C-NERGY Super C65 Conductive Carbon Black: Properties and Applications

C-NERGY Super C65 is a high-performance conductive carbon black designed for various industrial and technological applications, particularly those that require exceptional conductivity and electrical performance. This product is an advanced grade of carbon black, engineered to provide superior electrical conductivity, excellent dispersion properties, and versatility across multiple sectors, including electronics, batteries, coatings, and polymers.

In this article, we will explore the key properties of C-NERGY Super C65, its manufacturing process, and the broad range of applications where it has become a vital component.

What is C-NERGY Super C65 Conductive Carbon Black?

C-NERGY Super C65 is a type of conductive carbon black produced by Cabot Corporation, one of the leading manufacturers of specialty chemicals and performance materials. The material is engineered to deliver high electrical conductivity while maintaining a high surface area and excellent dispersion properties. Its structure and properties make it a highly effective material for applications requiring enhanced electrical conductivity, such as batteries, supercapacitors, conductive inks, and antistatic coatings.

The specific formulation of C-NERGY Super C65 allows it to provide the necessary conductivity without compromising other material properties such as mechanical strength, thermal stability, and optical transparency, making it suitable for a variety of demanding uses.

Key Properties of C-NERGY Super C65

1. High Conductivity

- One of the standout features of C-NERGY Super C65 is its high electrical conductivity, which is achieved through its nanostructured carbon network. This makes it ideal for applications where electrical conductivity is crucial, such as energy storage devices, conductive polymers, and antistatic coatings.

2. Large Surface Area

- C-NERGY Super C65 boasts a high surface area, which contributes to its ability to disperse evenly within a variety of matrix materials. This high surface area enhances its interaction with other components in applications like batteries and supercapacitors, improving overall performance.

3. Excellent Dispersion

- Proper dispersion of conductive carbon black in a host material is crucial to achieving consistent conductivity. C-NERGY Super C65 offers excellent dispersion properties, ensuring uniformity in conductive materials, which leads to enhanced mechanical properties and stability in the final product.

4. Thermal and Chemical Stability

- C-NERGY Super C65 offers superior thermal stability, which means it can operate effectively in high-temperature environments without degradation. Its chemical stability also makes it resistant to various environmental factors, such as moisture, which is essential for long-lasting performance in diverse applications.

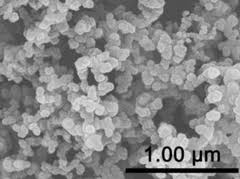

5. Particle Size Distribution

- The carbon black particles in C-NERGY Super C65 have a controlled and consistent particle size distribution. This allows for precise control over conductivity and ensures that the material can meet stringent performance standards.

Manufacturing Process of C-NERGY Super C65

The production of C-NERGY Super C65 involves the use of advanced carbon black manufacturing techniques, such as gas-phase pyrolysis and controlled oxidation, which allow for the precise control of particle size, surface area, and electrical conductivity. The process involves the following steps:

- Vaporization of Carbon Precursors: A hydrocarbon feedstock is vaporized in a high-temperature environment, breaking down the molecules to form carbon particles.

- Formation of Carbon Particles: These carbon particles then aggregate into clusters. Through carefully controlled conditions, the process produces nano-sized carbon aggregates, which are crucial for the material’s high conductivity and dispersibility.

- Surface Modification: The particles are often subjected to surface treatments to improve dispersion in different matrices. This is one of the key steps that ensure the material’s superior performance in various applications.

- Purification: Any residual impurities are removed during the production process to ensure that the final product is of the highest purity, enhancing its electrical and thermal conductivity.

Applications of C-NERGY Super C65

C-NERGY Super C65 is used across a wide range of applications that require conductive materials. Below are some of the most notable areas where this high-performance conductive carbon black is commonly applied:

1. Batteries and Supercapacitors

- Lithium-ion batteries and supercapacitors rely on conductive additives to improve the efficiency of electron and ion transport. C-NERGY Super C65 is used as a conductive additive in the electrode materials of batteries and supercapacitors, where its high conductivity and excellent dispersion enhance overall performance and capacity. It helps to reduce internal resistance and improve charge/discharge rates.

2. Conductive Polymers

- C-NERGY Super C65 is used in the formulation of conductive polymers, where its ability to disperse evenly in the polymer matrix ensures uniform electrical conductivity. These conductive polymers are used in electronic devices, antistatic coatings, and flexible electronics. It is especially useful in smart textiles, antistatic mats, and circuit boards.

3. Antistatic and Conductive Coatings

- One of the most common uses of conductive carbon black is in antistatic coatings and conductive coatings. C-NERGY Super C65 provides superior performance in protecting electronic devices from electrostatic discharge (ESD). It is used in coatings for electronics, automotive parts, and packaging materials.

4. Conductive Inks and Printing

- C-NERGY Super C65 is a key ingredient in the formulation of conductive inks, which are used in printed electronics, RFID tags, and flexible displays. The material’s ability to provide high conductivity while maintaining printability makes it an essential component in modern printing technologies.

5. Electromagnetic Interference (EMI) Shielding

- C-NERGY Super C65 can also be used in EMI shielding applications, where its conductive properties are employed to block or mitigate electromagnetic radiation. This is important in the electronics industry, where shielding is required to ensure the proper functioning of devices like smartphones, computers, and medical equipment.

6. Automotive and Aerospace

- In industries such as automotive and aerospace, C-NERGY Super C65 is used in coatings and composite materials to reduce the risk of electrostatic discharge and improve the performance of electronic systems in vehicles and aircraft. It is especially useful in antistatic coatings for interior components and fuel systems.

Advantages of C-NERGY Super C65 Over Other Conductive Carbon Blacks

While there are many types of conductive carbon blacks available on the market, C-NERGY Super C65 stands out for several reasons:

- Superior Dispersion: C-NERGY Super C65 offers excellent dispersion, which ensures uniform conductivity and better integration into various matrices. This results in improved mechanical properties and thermal performance.

- Higher Electrical Conductivity: Compared to conventional carbon blacks, C-NERGY Super C65 delivers higher conductivity with lower loadings, meaning you can achieve the same or better performance with less material.

- Versatility: The material is highly adaptable to various applications, including energy storage, coatings, and polymers, making it suitable for a wide range of industries.

- Enhanced Purity: The high purity of C-NERGY Super C65 ensures that there are no contaminants to interfere with the performance of sensitive applications, such as biomedical devices or electronics.

Conclusion

C-NERGY Super C65 is a high-performance conductive carbon black with a range of superior properties that make it ideal for advanced applications in energy storage, electronics, coatings, and composite materials. Its high electrical conductivity, excellent dispersion, and thermal stability position it as a leading material for industries that require efficient and reliable conductive additives.

With ongoing advancements in materials science, the demand for high-performance conductive carbon blacks like C-NERGY Super C65 is expected to grow, driven by the need for better performance in energy devices, electronics, and smart materials. As industries continue to innovate and evolve, C-NERGY Super C65 will play an essential role in shaping the future of advanced materials and technological applications.