Carbon Nanotube Composite Electrodes for Fuel Cell Applications

Fuel cells are considered one of the most promising technologies for clean energy production, offering a highly efficient and environmentally friendly alternative to conventional energy sources. The performance of fuel cells heavily depends on the properties of the electrodes, which are responsible for the electrochemical reactions that generate electricity. Recent advances in nanotechnology have led to the development of carbon nanotube (CNT) composite electrodes, which significantly enhance the performance of fuel cells. This article explores the role of carbon nanotubes (CNTs) in composite electrodes for fuel cell applications, focusing on their properties, benefits, challenges, and future prospects.

1. What Are Carbon Nanotubes (CNTs)?

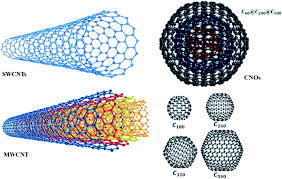

Carbon nanotubes (CNTs) are nano-sized structures composed of rolled-up sheets of graphene, a two-dimensional carbon material. There are two primary types of CNTs:

- Single-Walled Carbon Nanotubes (SWCNTs): These consist of a single graphene sheet rolled into a cylinder.

- Multi-Walled Carbon Nanotubes (MWCNTs): These consist of several concentric graphene cylinders.

CNTs exhibit a range of exceptional properties, including:

- High electrical conductivity

- High surface area

- Mechanical strength

- Thermal conductivity

- Chemical stability

These characteristics make CNTs an ideal material for fuel cell electrodes, where they are used to facilitate the electrochemical reactions that generate energy.

2. The Role of Carbon Nanotube Composite Electrodes in Fuel Cells

In fuel cell systems, electrodes play a critical role in energy conversion. The anode and cathode are where the oxidation and reduction reactions occur, respectively. For efficient fuel cell operation, the electrodes must possess high electrical conductivity, large surface area, chemical stability, and the ability to facilitate ion transfer.

Carbon nanotube composite electrodes combine CNTs with other materials (such as metals, polymers, or ceramics) to enhance these properties. CNTs are incorporated into the electrode matrix to improve electrochemical performance and provide:

- High electrical conductivity to promote efficient electron transfer.

- Large surface area to support a high number of active sites for reaction catalysis.

- Mechanical strength to ensure structural integrity during operation.

3. Benefits of Using Carbon Nanotube Composites in Fuel Cells

The integration of CNTs into composite electrodes offers several distinct advantages for fuel cell applications:

a. Enhanced Electrical Conductivity

One of the primary advantages of using CNTs in composite electrodes is their high electrical conductivity. This allows for efficient electron transport between the electrode and the electrolyte, improving the overall efficiency of the fuel cell. The conductivity of CNTs ensures that electrons can flow freely, which is particularly important for the anode in fuel cells where the oxidation of fuel occurs.

b. Increased Surface Area

CNTs have an incredibly high surface area, which provides a larger number of active sites for electrochemical reactions. This increased surface area improves the fuel cell’s reaction kinetics, making it more efficient at converting fuel (such as hydrogen) into electricity.

c. Enhanced Catalytic Activity

The high surface area and the defects present on CNT surfaces can act as catalytic sites for the reactions that occur in the fuel cell. When CNTs are combined with catalyst materials like platinum (Pt) or platinum alloys, they can enhance the overall catalytic activity of the electrodes, reducing the need for large amounts of expensive catalysts.

d. Mechanical Strength and Durability

CNTs are known for their exceptional mechanical properties, including high tensile strength and flexibility. These properties contribute to the overall structural stability of composite electrodes, ensuring that they can withstand the harsh operating conditions of fuel cells, such as high temperature and pressure.

e. Improved Proton Conductivity

When combined with proton-conducting materials (such as polymer electrolytes), CNT composites can also enhance the proton conductivity in fuel cell electrodes. This facilitates more efficient ion transfer, further improving the fuel cell’s overall performance.

4. Synthesis Methods for Carbon Nanotube Composite Electrodes

The synthesis of carbon nanotube composite electrodes typically involves combining CNTs with other materials through various methods. Some common techniques include:

a. Solution Mixing

In this method, CNTs are dispersed in a solvent and mixed with other components such as polymers, catalysts, or conducting materials. The mixture is then dried or cured to form the composite material. Solution mixing is relatively simple and can be scaled up for large-scale production.

b. Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a popular method for producing CNTs directly onto substrates such as metal foils or electrode materials. In CVD, carbon-containing gases are introduced into a reaction chamber, where they decompose to form CNTs on the substrate surface. This method allows for precise control over the CNT structure and density, which is important for optimizing the electrode’s performance.

c. Electrochemical Deposition

Electrochemical deposition is used to deposit CNTs onto an electrode surface by applying an electric current in an electrolyte containing carbon precursors. This technique can be used to create CNT films on electrodes, which can then be used in fuel cell applications.

d. Sol-Gel Process

In the sol-gel method, metal oxide precursors are mixed with CNTs and then processed into a gel. The gel is subsequently heat-treated to form a solid composite material. This method is useful for creating nanostructured composite electrodes with enhanced catalytic properties.

5. Applications of Carbon Nanotube Composite Electrodes in Fuel Cells

a. Proton Exchange Membrane Fuel Cells (PEMFC)

In PEMFCs, carbon nanotube composite electrodes can significantly enhance the fuel cell’s performance by improving electronic conductivity and catalytic activity. The combination of CNTs with platinum-based catalysts increases the efficiency of the catalytic reaction, reducing the amount of platinum needed and lowering fuel cell costs.

b. Direct Methanol Fuel Cells (DMFC)

In DMFCs, which use methanol as the fuel, CNT-based composite electrodes are used to improve the oxidation of methanol at the anode and oxygen reduction at the cathode. The high surface area and catalytic properties of CNTs enable faster reaction rates, enhancing the overall performance of the DMFC.

c. Alkaline Fuel Cells (AFC)

In alkaline fuel cells, CNTs are used to improve the conductivity and catalytic efficiency of the electrodes. The incorporation of CNTs can also reduce the crossover of fuel molecules, improving the efficiency of these fuel cells.

d. Microbial Fuel Cells (MFC)

In microbial fuel cells, which use microorganisms to catalyze the breakdown of organic matter to generate electricity, CNT composites are used to create high-performance electrodes that facilitate electron transfer from the microbes to the electrode surface.

e. Solid Oxide Fuel Cells (SOFC)

For SOFCs, CNT composites can be used as anode materials. The conductive nature and stability of CNTs make them ideal for improving the efficiency and durability of solid oxide fuel cells, especially at high operating temperatures.

6. Challenges and Future Directions

While CNT composite electrodes offer numerous advantages, there are still challenges that need to be addressed for their widespread adoption in fuel cell technology:

a. High Cost of CNTs

Despite their outstanding properties, CNTs remain expensive to produce, which adds to the cost of fuel cells. Researchers are working on improving the synthesis methods to make CNT production more cost-effective and scalable.

b. Dispersion Issues

Achieving a uniform dispersion of CNTs in composite materials can be difficult due to their tendency to agglomerate. Methods like surface functionalization and dispersing agents are being explored to address this issue.

c. Catalyst Utilization

While CNTs enhance the catalytic properties of fuel cell electrodes, optimizing their interaction with catalyst materials (such as platinum) to achieve maximum efficiency is an ongoing area of research.

7. Conclusion

Carbon nanotube composite electrodes hold significant promise for enhancing the performance of fuel cells, particularly in terms of electrical conductivity, catalytic activity, mechanical strength, and chemical stability. Their use in fuel cell technologies, such as PEMFCs, DMFCs, and SOFCs, is expected to lead to more efficient and cost-effective energy conversion systems. While challenges like cost and dispersion issues remain, ongoing advancements in nanotechnology and materials science are likely to overcome these hurdles, paving the way for the future widespread use of CNT composites in fuel cells.