Aluminium Nanoparticles For Solar Cell

Aluminium Nanoparticles Improved thermoelectric properties of Aluminum Zinc Oxide (AZO) thin films

deposited by radio frequency (RF) and pulsed Direct Current (DC) magnetron sputtering at room temperature

are reported. In both techniques films were deposited using sintered and non-sintered targets produced from

nano-powders. It is confirmed that both the Al doping concentration and film thickness control the

thermoelectric, optical and structural properties of these films.

SOLAR CELL SENSOR Delafossite CuAlO2 belongs to a family of transparent conducting oxides (TCOs) – oxides

with low electrical resistivity and high visual light transparency – that show promise in multiple applications

including: liquid crystal displays, touch screens, gas sensors, thermoelectric devices, solar cells, dilute magnetic

semiconductors, light-emitting diodes, etc. CuAlO2 nanoparticles have also been used as thermo-catalysts in the

thermal photo-catalytic reactions for the evolution of hydrogen gas from water splitting. p–n junction

photovoltaic using CuAlO2 and In2O3, respectively, would allow visible light to pass through the cell while

producing electricity via the absorption of ultraviolet radiation.

Aluminium Nanoparticles has a layered crystal structure with Cu atoms between AlO2 layers forming O–Cu–O

pillars CuAlO2 has indirect and direct band gaps of 1.2 and 3.6 eV respectively, high transparency (80%) in the

visible region, and high light-to-electricity conversion efficiencies in solar cells . Photocurrents ranging from 0.02

mA/cm2 to 0.08 mA/cm2 have been observed when CuAlO2 nanoparticles (300 nm) were used as the

photocathode materials in p-type DSSCs, while delafossite CuGaO2 nanoplates produced comparatively high

photocurrents (0.384 mA/cm2) in the region of visible light using polypyridyl Co3+/2+(dtb-bpy) as the

electrolyte and the organic P1 dye Higher cathodic photocurrents (Jsc = 0.954 mA/cm2 under AM1.5 sun) were

observed in p-type dye sensitized solar cells (DSSCs) fabricated using these CuAlO2 nanoparticles compared to

the previous reports on delafossite CuBO2 (B = Al, Ga) nanoparticles. Enhanced current efficiency in these solar

cells is attributed to the nano-sized particles and narrow particle size distributions of nanocrystalline delafossite

Aluminium Nanoparticles thermoelectric properties of Aluminum Zinc Oxide (AZO) thin films deposited by

radio frequency(RF) and pulsed Direct Current (DC) magnetron sputtering at room temperature are reported. In

bothtechniques films were deposited using sintered and non sintered targets produced from nano-powders. It is

confirmed that both the Al doping concentration and film thickness control the thermoelectric, optical and

structural properties of these films. An efficient application of thermoelectric (TE) materials in devices requires

materials with high Seebeck coefficients (S ¼DV/DT), low thermal conductivity (k), and low resistivity (r) to attain

a large gure of merit (ZT ¼ S2T/kr). By nanostructuring materials the ZT value has improved to over 1 at 300 K,

taking Bi2Te2/Sb2Te2 superlattices (ZT > 2) and n-type PbSeTe (ZT ¼ 1.5) materials as examples.

TE applications it has mainly been explored with bulk dimensions and with different dopants: Zn1_xMxO, AZO if

M ¼ Al and GZO if M ¼ Ga,5 Zn1_(x+y)GaxInyO (x + y ¼ 0.007)6 or ZnAlO/In– ZnAlO quantum well multilayers.

Although this power output power is small for most applications, it is already comparable to full devices

comprising 100 thin lm thermocouples of Sb2Te3/Bi2Te3, also with planar geometry, which for DT ¼ 20 K have a

maximum power output of 7 nW.35 By connecting this n-type thermoelectric element with a compatible p-type

element, such as Cr : V2O5 20 and using an appropriate combination of series and parallel interconnections

between the TE elements it will be possible to design devices with higher output powers to meet the needs of

low power TE module applications.

Enhanced Ionic Liquids (NEILs) for Concentrated Solar Power (CSP)

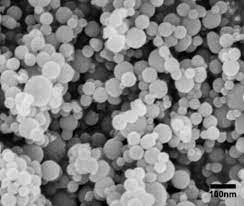

Aluminium Nanoparticles Enhanced Ionic Liquids (NEILs) were synthesized by dispersing aluminum

oxide(Al2O3) Nanoparticles in 1-butyl-3-methylimidazolium bis {(trifluoromethyl) sulfonyl}imide, ([C4mim]

[NTf2]) ionic liquids (ILs). Concentrated Solar Power (CSP) is one of the developing alternative energy

technology, where mirrors or lenses are used to concentrate sunlight from a large area and are stored in a

collector filled with heat transfer fluid (HTF). Later on the energy of those HTF is used to produce steam for

power generation. Commonly used HTF such as Therminol VP-1 (eutectic mixture of biphenyl and diphenyl

oxide), thermal oil, and molten salt have low decomposition temperature and high melting point, which are

affecting the energy storage capacity and reducing the overall system efficiency, resulting in an increase of the

operating cost. Therefore, there is an acute need for the new energy-efficient HTFIonic liquids (ILs) are a class of

molten salt, which has melting point below 100 _C, high thermal stability, and negligible vapour pressure.

Aluminium Nanoparticles

These properties make them as a potential candidate for CSP applications over the currently used HTF addition,

nanofluids, which are defined as dispersion of metallic (Cu, Ag, and Au) or non-metallic (Al2O3, CuO, TiO2)

particles with one dimension less than 100 nmM in a base liquid, have great attraction due to their enhanced

thermophysical properties and enhanced ththeir potential applicability as cooling media for high heat

generating Melectronic device, nuclear plant, automobile industry. These enhanced heat transfer properties of

nanofluids encourage the researchers to combine these two (nanoparticles and ionic liquids) growing interests,

forming the Nanoparticle Enhanced Ionic Liquids (NEILs) by dispersing small amounts of nanoparticles into base

ILs. The practical applications of NEILs are as heat transfer fluids; and can be used for heat exchange in chemical

plants, absorption cooling cycle systems, and solar thermal power generationermal performance.