What is Conductive Carbon Paste? – Nanomaterial

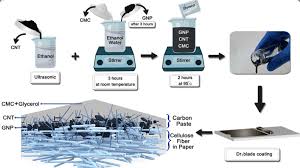

Conductive Carbon Paste is a type of nanomaterial that incorporates carbon-based elements such as graphite, carbon black, or carbon nanotubes to enhance electrical conductivity. It is commonly used in various industrial and technological applications, including electronics, energy storage, sensors, and conductive coatings. The paste typically consists of fine carbon particles suspended in a binder or solvent, making it versatile and easy to apply in a variety of forms and onto different surfaces.

1. Composition of Conductive Carbon Paste

Conductive carbon paste is composed of:

- Carbon fillers: These include carbon black, graphite, graphene, or carbon nanotubes, which are responsible for the paste’s electrical conductivity. The choice of carbon filler depends on the desired conductivity and application.

- Binder: A resin or polymer is used to hold the carbon particles together and provide adhesion to the substrate. Common binders include epoxy, acrylic, or polyvinyl chloride (PVC).

- Solvent or carrier: This helps to make the paste workable and provides the right consistency for application. The solvent evaporates after the paste is applied, leaving behind a conductive carbon layer.

2. Properties of Conductive Carbon Paste

The key properties of conductive carbon paste include:

- Electrical conductivity: The primary property that makes carbon paste valuable in various applications. The conductivity is determined by the type and amount of carbon filler used.

- Viscosity: Conductive carbon pastes typically have a controlled viscosity to ensure they can be applied smoothly and uniformly.

- Adhesion: The paste must adhere to various surfaces, including metals, ceramics, and plastics, without peeling or cracking over time.

- Flexibility: Some conductive carbon pastes are designed to maintain flexibility after curing, which is useful in applications where the substrate might undergo mechanical stress or deformation.

- Durability: The paste must be resistant to environmental factors such as heat, moisture, and chemical exposure, especially in long-term applications like electronics.

3. Applications of Conductive Carbon Paste

A. Electronics and Electrical Components

- Conductive adhesives: Carbon paste is used in the manufacture of conductive adhesives for bonding electrical components, such as sensors, circuit boards, and electronic devices.

- Printed circuit boards (PCBs): Conductive carbon paste is applied in some PCB manufacturing processes to create conductive pathways on the surface.

- Flexible electronics: Carbon pastes are often used in the creation of flexible electronics, where the paste forms conductive traces that bend with the substrate.

B. Energy Storage and Batteries

- Electrodes for batteries: Conductive carbon paste is used in the manufacturing of electrodes for lithium-ion and other types of batteries. The carbon paste ensures good electrical conductivity between the electrode material and current collectors.

- Supercapacitors: In energy storage devices like supercapacitors, conductive carbon paste helps in maintaining high conductivity, which is essential for charge and discharge cycles.

C. Sensors

- Gas sensors: Conductive carbon pastes are applied in gas sensors to detect gases such as carbon dioxide, oxygen, or volatile organic compounds. The paste’s conductivity can change in the presence of certain gases, allowing for detection.

- Biosensors: In biosensors, carbon paste is used as a conductive layer that can interact with biological substances. For example, in glucose sensors, the paste can act as a transducer for electrical signals generated by enzymatic reactions.

D. Conductive Coatings

- Antistatic coatings: Carbon paste can be used to coat surfaces, providing electrical conductivity to prevent static buildup in sensitive environments, such as in electronics manufacturing.

- Electromagnetic shielding: Conductive carbon paste is applied to materials that require protection from electromagnetic interference (EMI). This is commonly used in aerospace, automotive, and telecommunications industries.

E. Thermal Conductivity

- Conductive carbon pastes also play a role in improving thermal conductivity in various industrial applications. Carbon-based materials are well-known for their ability to conduct heat, and when used in paste form, they can be applied to manage heat flow in electronic devices, motors, or machinery.

4. Advantages of Using Conductive Carbon Paste

- Cost-Effective: Compared to other conductive materials like silver or copper, carbon-based materials are relatively inexpensive, making conductive carbon paste a more affordable solution for many applications.

- Easy Application: The paste form allows for easy application on various surfaces and can be used in both large-scale industrial settings and precision-based applications.

- Customization: The paste can be formulated with different types and amounts of carbon to achieve specific conductivity levels, making it versatile for a range of applications.

- Environmental Friendliness: Many conductive carbon pastes use non-toxic, environmentally friendly carbon sources, making them safer for industrial and consumer applications compared to some metal-based alternatives.

5. Challenges of Conductive Carbon Paste

- Limited Conductivity Compared to Metals: While conductive carbon paste is effective for many applications, its electrical conductivity is still lower than that of metals like copper or silver. Therefore, its use is limited to applications where extremely high conductivity is not required.

- Durability in Harsh Conditions: The paste’s durability in harsh conditions (e.g., extreme temperatures, exposure to chemicals, or mechanical wear) can sometimes be a concern, depending on the binder and carbon material used.

- Consistency in Manufacturing: Ensuring the consistency of paste composition during large-scale production is a challenge, as variations in the particle size of the carbon fillers or binder materials can affect the final performance.

6. Future Directions in Conductive Carbon Paste

- Nanomaterial Integration: The integration of advanced carbon nanomaterials, such as graphene or carbon nanotubes, into the paste can significantly enhance its conductivity and mechanical properties. This can open up new applications in high-performance electronics, energy storage, and sensors.

- Environmentally Friendly Formulations: Researchers are exploring eco-friendly solvents and binders to make carbon pastes more sustainable and reduce the environmental impact of their production and disposal.

- Advanced Coatings for Specific Applications: With the rise of flexible and wearable electronics, conductive carbon pastes are being researched for use in applications where materials must withstand bending, stretching, or wear over time.

7. Conclusion

Conductive carbon paste is a versatile nanomaterial with a wide range of applications in electronics, energy storage, sensors, and coatings. Its unique properties, such as high surface area, tunable conductivity, and ease of application, make it an attractive solution for many industries. However, challenges related to its conductivity, durability, and consistency must be addressed to unlock its full potential in advanced technological applications. With continued research and development, conductive carbon paste is poised to play a significant role in future innovations in materials science and electronics.