Using Nanoimprinting with Applications in Optics

Nanoimprinting is a nanofabrication technique that has revolutionized the production of nanostructures, particularly in the fields of optics, electronics, and biotechnology. By utilizing nano-scale patterns, nanoimprinting can achieve high precision and low-cost fabrication, which are critical for advancing the performance of optical devices and systems.

This article explores the process of nanoimprinting, its applications in optical technologies, and how it is enabling innovations in lens design, photonic devices, displays, and more.

What is Nanoimprinting?

Nanoimprint lithography (NIL) is a top-down fabrication technique used to create highly detailed nano-patterns on various surfaces. Unlike traditional photolithography, which relies on light exposure to a photoresist material, nanoimprinting uses a stamp or mold with nanoscale features to physically imprint these features onto a substrate, typically with the use of pressure and heat.

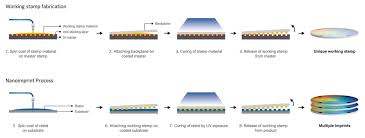

The process can be broken down into the following key steps:

- Mold Preparation: A mold with the desired nano-pattern (such as lines, holes, or complex structures) is prepared, often using electron beam lithography.

- Resist Coating: A thin layer of a thermoplastic or UV-curable polymer is applied to the substrate.

- Imprinting: The mold is brought into contact with the resist, and pressure is applied. The resist deforms and adopts the shape of the mold.

- Curing and Release: If UV-curable resists are used, the material is cured with UV light. The mold is then carefully removed, leaving behind the nanoscale pattern on the substrate.

Nanoimprinting offers several advantages, including high resolution, low cost, high throughput, and compatibility with a variety of materials.

Applications of Nanoimprinting in Optics

The precision and versatility of nanoimprinting make it an ideal tool for creating advanced optical components. Here are some of the key areas where nanoimprinting is currently being applied or has the potential to revolutionize the optics industry:

1. Photonic Devices

Photonic devices are components that manipulate and utilize light for various applications, such as in telecommunications, computing, and sensing. Nanoimprinting is instrumental in producing the intricate structures required for these devices, particularly for photonic crystals, optical waveguides, and light-emitting diodes (LEDs).

- Photonic Crystals: Nanoimprinting is used to fabricate two-dimensional (2D) and three-dimensional (3D) photonic crystals, which are materials with a periodic structure on the scale of the wavelength of light. These structures can control the flow of light and are used in optical fibers, light switches, and cavity resonators for quantum computing.

- Waveguides: Nanoimprinting enables the creation of precise optical waveguides that can direct light with minimal loss and distortion. These waveguides are integral in on-chip optical interconnects, improving the speed and efficiency of data transfer in optical communications.

2. Lens and Mirror Fabrication

In traditional optics, lenses and mirrors are fabricated using milling or casting methods, which are time-consuming and expensive. Nanoimprinting can provide a more efficient way to produce micro-lenses and nano-lenses with high precision.

- Focusing Lenses: Nanoimprinting can produce aspherical micro-lenses that can focus light with higher efficiency and at smaller scales than traditional methods. This is particularly useful for miniaturized cameras, microscopy, and endoscopic devices.

- Reflective Surfaces: Nanoimprinting is also used for creating nano-structured reflective surfaces that improve light control. Micro-mirrors and nano-mirrors can enhance optical devices such as display systems and high-resolution imaging systems.

3. Metamaterials and Plasmonics

Metamaterials are materials engineered to have properties not typically found in natural materials, particularly in their interaction with electromagnetic waves. Plasmonics, a sub-field of metamaterials, focuses on the manipulation of surface plasmons—collective oscillations of electrons that are excited by light at metal-dielectric interfaces.

- Nanoimprinted Metamaterials: By imprinting nanoscale structures, nanoimprinting allows the creation of metamaterials with unique properties, such as negative refractive index or perfect absorption. These materials have vast applications in invisibility cloaks, superlenses, and optical sensors.

- Plasmonic Structures: Nanoimprinting can also be used to fabricate plasmonic nanostructures that enhance light-matter interactions. These structures are used in biosensors, surface-enhanced Raman spectroscopy (SERS), and other advanced optical sensing applications.

4. Display Technology

Nanoimprinting is increasingly used in the development of next-generation display technologies, particularly in OLEDs (organic light-emitting diodes) and micro-LEDs. The technique allows for the creation of nanostructured electrodes, light extraction layers, and optical films, which significantly enhance the brightness, efficiency, and performance of displays.

- OLED Displays: By using nanoimprinted patterns on the electrode surfaces of OLEDs, light extraction efficiency can be improved, resulting in brighter displays with lower power consumption.

- Micro-LEDs: Nanoimprinting is used to create uniform micro-LED arrays that can be used in high-definition displays and AR/VR (augmented reality/virtual reality) systems. This technique enables the precise placement and patterning of LEDs, leading to higher resolution and better color accuracy.

5. Holography and 3D Displays

Holography is a technique used to record and reproduce 3D images using light interference. Nanoimprinting is helping to make holographic displays more affordable and efficient.

- Holographic Elements: Nanoimprinting allows the precise creation of holographic optical elements (HOEs), which are used to manipulate light in 3D displays and projection systems.

- 3D Optical Data Storage: Nanoimprinted structures can also be used for 3D optical data storage, where data is encoded in the form of 3D holograms. This approach can significantly increase the storage density of optical disks.

6. Quantum Optics

Quantum optics is an emerging field that leverages the quantum properties of light for a variety of advanced technologies, including quantum computing, quantum communication, and quantum sensing. Nanoimprinting plays a key role in creating the nanostructures needed for controlling quantum light states.

- Quantum Dots: Nanoimprinting is used to create quantum dots and nanowires for applications in quantum information and photonics. These nanostructures can be used for single-photon sources and quantum sensors, which are vital for quantum computing.

Advantages of Nanoimprinting in Optics

- High Resolution: Nanoimprinting can achieve sub-10 nm resolution, allowing for the fabrication of intricate structures that are necessary for advanced optical applications.

- Scalability: Nanoimprinting is highly scalable, enabling the mass production of optical components, from nanostructured coatings to optical components for consumer electronics.

- Low Cost: Compared to traditional photolithography and other high-precision fabrication techniques, nanoimprinting is relatively cost-effective, making it suitable for large-scale commercial production.

- Flexibility: Nanoimprinting can be applied to a wide range of materials, including polymers, semiconductors, metals, and dielectrics, allowing for a broad array of optical applications.

Challenges and Future Outlook

While nanoimprinting offers numerous benefits, there are still challenges to overcome, particularly in material selection, pattern fidelity, and process optimization for large-area patterning. Additionally, alignment precision and mold durability are key areas of focus for improving the overall efficiency and yield of nanoimprinting processes.

However, as the technology matures, nanoimprinting is expected to play a critical role in the future of optics, enabling the development of smaller, more efficient, and higher-performance optical devices. With further advancements in nanomaterial engineering and process control, nanoimprinting could become a cornerstone technology for the next generation of optical communication, displays, and quantum devices.

Conclusion

Nanoimprinting has the potential to revolutionize the field of optics by enabling the precise and cost-effective production of complex nanostructures. From photonic devices and displays to quantum optics and metamaterials, nanoimprinting is paving the way for innovations that will enhance the performance and functionality of optical systems. As the technique continues to evolve, its role in next-generation optics is likely to become even more critical, offering novel solutions to meet the growing demands of the optical and photonics industries.