Use of Graphene Sheets in Nanoelectromechanical Systems (NEMS)

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has garnered tremendous attention due to its exceptional mechanical, electrical, and thermal properties. Among its various applications, Graphene Sheets have shown significant potential in the development of Nanoelectromechanical Systems (NEMS). NEMS are miniature devices that integrate mechanical and electrical components on the nanoscale. These systems are revolutionizing fields such as sensors, actuators, communication devices, and energy harvesting. In this article, we explore the role of graphene sheets in NEMS and how their remarkable properties are making them a critical material for advancing nanotechnology.

What Are Nanoelectromechanical Systems (NEMS)?

Nanoelectromechanical Systems (NEMS) are extremely small mechanical devices that combine electrical and mechanical functionalities at the nanoscale. NEMS consist of components such as sensors, actuators, and oscillators, which can detect, manipulate, or transmit signals at incredibly small sizes. These systems operate at extremely high frequencies and are often designed to perform specialized tasks, such as precision measurements, data transmission, or energy conversion.

NEMS devices have applications in various industries, including biotechnology, communications, electronics, and environmental monitoring. The development of NEMS has been facilitated by the integration of materials that can offer both mechanical strength and electrical conductivity, making graphene an ideal candidate for these applications.

Properties of Graphene Sheets

Graphene sheets exhibit several remarkable properties that make them highly suitable for NEMS applications:

- High Mechanical Strength

- Graphene is known for its exceptional mechanical properties, including a tensile strength that is more than 100 times greater than steel. This strength, combined with its flexibility, makes graphene ideal for use in mechanical components that need to withstand high stress while maintaining structural integrity at the nanoscale.

- High Electrical Conductivity

- Graphene has high electrical conductivity, enabling efficient charge transport within NEMS devices. This property is crucial for integrating electrical and mechanical functionalities in NEMS, especially for sensors, actuators, and energy harvesting systems where rapid electrical responses are required.

- High Surface Area

- Graphene’s large surface area (around 2630 m² per gram) provides substantial room for interaction with other materials or molecules. This makes graphene sheets particularly effective in applications such as sensors where high surface interaction is critical for sensitivity and detection accuracy.

- Excellent Thermal Conductivity

- Graphene has remarkable thermal conductivity, making it an excellent material for heat dissipation. This property is particularly valuable in NEMS devices where heat management is essential to ensure stable and efficient operation.

- Flexibility and Thinness

- Graphene is a two-dimensional material, only one atom thick, giving it outstanding flexibility and lightness. This allows it to be used in extremely compact NEMS devices, which are crucial for applications where size and weight are key constraints.

Applications of Graphene Sheets in NEMS

- Graphene-Based NEMS Sensors

- Graphene sheets are widely used in the development of ultra-sensitive sensors. Due to their large surface area and high mechanical strength, graphene-based sensors can detect small changes in environmental conditions such as temperature, pressure, and chemical concentrations. These sensors can be used in a variety of applications, including biomolecular sensing, environmental monitoring, and health diagnostics.

- The sensitivity of graphene-based sensors is enhanced due to the strong interaction between the material and the target molecules, enabling precise measurements at the nanoscale. For example, graphene can be used to detect gas molecules, biomarkers, and toxic compounds at low concentrations.

- Graphene Actuators and Membranes

- Graphene-based actuators can convert electrical energy into mechanical motion with high precision, enabling applications in microelectronics and nano-robotics. In NEMS, actuators made from graphene sheets can be used to perform mechanical tasks such as vibration control, precise positioning, or surface manipulation.

- Graphene membranes, which are extremely thin and flexible, are also used in filtering and separation processes. These membranes can be used to selectively allow the passage of specific molecules while blocking others, making them useful for applications in water purification and molecular sieving.

- Energy Harvesting in NEMS

- Graphene sheets can play a significant role in energy harvesting systems within NEMS. Their ability to generate electricity from mechanical motion makes them suitable for use in piezoelectric and triboelectric nanogenerators, which convert mechanical energy into electrical energy. This technology can be used to power small devices, sensors, or wearables by harnessing ambient vibrations or motion.

- Graphene-Based NEMS Resonators

- Graphene sheets can be used as resonators in NEMS applications, where they vibrate at specific frequencies. These resonators are useful for precise measurements, such as mass sensing, frequency detection, and timekeeping. The high mechanical strength and stability of graphene make it an ideal material for such applications, as it can maintain its performance over long periods without degradation.

- Graphene-Based NEMS Transistors and Memory Devices

- Graphene transistors are gaining traction for use in NEMS because of their ability to operate at high speeds while consuming very low power. This makes graphene-based transistors ideal for high-frequency switching applications and could be a foundation for the development of ultra-fast, energy-efficient memory devices in nanoelectronics.

- Graphene’s electrical properties also make it a strong candidate for use in quantum memory and quantum computing systems, where materials need to support fast processing and high coherence times.

- Integrated NEMS Devices

- The integration of graphene sheets into multi-functional NEMS devices, such as those combining sensing, actuation, and communication, could pave the way for highly compact, all-in-one systems. These integrated devices could be used in various applications, including wearable electronics, health monitoring, and environmental sensing, where small size and efficiency are crucial.

Challenges and Future Prospects

While graphene holds great promise for NEMS applications, there are several challenges to overcome:

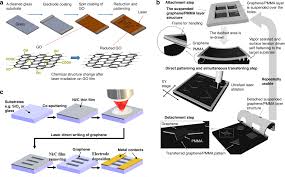

- Scalability: Manufacturing high-quality graphene sheets at large scales for commercial applications remains a challenge. Efficient production methods, such as chemical vapor deposition (CVD) or liquid-phase exfoliation, need to be optimized to reduce costs and increase scalability.

- Integration with Other Materials: Integrating graphene with other materials in NEMS devices requires careful consideration of compatibility, especially when combining graphene with metals, semiconductors, or polymers. This is important for ensuring the performance, durability, and stability of NEMS devices.

- Cost: Despite its potential, the cost of high-quality graphene remains a barrier for widespread use in commercial NEMS applications. As production methods improve and economies of scale come into play, the cost of graphene-based systems is expected to decrease.

Conclusion

Graphene sheets are paving the way for advancements in Nanoelectromechanical Systems (NEMS) due to their exceptional mechanical, electrical, and thermal properties. Applications in sensing, actuation, energy harvesting, and nanoelectronics highlight the versatility of graphene in the development of highly compact and efficient NEMS devices. Although challenges such as scalability and cost remain, the future of graphene in NEMS holds immense potential, with ongoing research likely to lead to groundbreaking innovations across various industries. As production techniques evolve, the integration of graphene in NEMS will play a key role in advancing the capabilities of nanoelectronics, healthcare, environmental monitoring, and energy systems.