The Use of Iron Oxide Nanoparticles in Separation Processes in the Petroleum Industry

The petroleum industry plays a pivotal role in global energy production, and ensuring the efficient separation of oil, water, and other contaminants is crucial for optimizing production and minimizing environmental impact. In this regard, iron oxide nanoparticles (Fe3O4 NPs) have emerged as an innovative solution for improving the separation processes within the petroleum industry. This article explores how iron oxide nanoparticles are utilized to enhance oil-water separation, reduce contamination, and promote environmental sustainability in petroleum operations.

1. What Are Iron Oxide Nanoparticles?

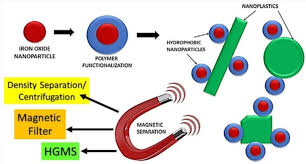

Iron oxide nanoparticles are nanoscale particles of iron oxide, commonly in the forms of magnetite (Fe3O4) or hematite (Fe2O3). These nanoparticles have unique properties such as high surface area, magnetic characteristics, and tunable chemical reactivity, which make them highly effective in various industrial applications, including catalysis, water treatment, and separation processes in the petroleum sector.

The small size of these particles allows them to interact effectively with oil and water molecules, enabling efficient separation and purification. They also possess magnetic properties that allow for easy recovery from complex systems, making them a sustainable solution for repeated use in separation processes.

2. Applications of Iron Oxide Nanoparticles in Petroleum Separation Processes

The petroleum industry requires effective methods to separate crude oil from water, gas, and other impurities. Iron oxide nanoparticles are used in various stages of petroleum processing for their unique abilities to enhance separation and purification:

A. Oil-Water Separation

One of the most important applications of iron oxide nanoparticles is in oil-water separation. In many petroleum extraction and refining processes, large amounts of water are mixed with crude oil. Efficient separation of these two phases is critical to avoid contamination and ensure the quality of the extracted oil.

Iron oxide nanoparticles, particularly magnetite, are highly effective in adsorbing water molecules and aiding in the separation of water from oil. Their magnetic properties allow for easy removal from the system using an external magnetic field, thus reducing the need for chemical additives or complex filtration systems. This process can be applied to both emulsified oil-water mixtures and free water in crude oil production.

B. Heavy Metal Removal and Contaminant Adsorption

Iron oxide nanoparticles are highly effective at removing heavy metals and other toxic contaminants from water in the petroleum industry. They have a large surface area and high affinity for certain metals, such as lead (Pb), cadmium (Cd), and arsenic (As), which are often present in produced water from oil extraction. The adsorption of these toxic metals onto the surface of iron oxide nanoparticles not only helps clean the water but also ensures that the produced water meets environmental standards before disposal or reuse.

In addition to metals, these nanoparticles can also adsorb organic pollutants, such as hydrocarbons and polycyclic aromatic hydrocarbons (PAHs), that can be harmful to the environment.

C. Enhanced Demulsification

In some cases, crude oil emulsions are difficult to separate due to the formation of stable oil-water mixtures. Iron oxide nanoparticles can enhance the demulsification process by destabilizing the emulsion. Their high surface energy and the ability to adsorb onto the emulsion droplets help in breaking the emulsion into separate phases. This process is typically enhanced by combining the nanoparticles with certain surfactants or coalescing agents.

The use of iron oxide nanoparticles in demulsification reduces the need for harsh chemicals and mechanical separation methods, offering a more environmentally friendly and cost-effective solution.

D. Magnetically Enhanced Filtration

Iron oxide nanoparticles are also incorporated into magnetic filtration systems used to separate particulate matter and contaminants from petroleum fluids. The magnetic properties of these nanoparticles allow them to be incorporated into filters, which can then be removed using an external magnetic field, making the process more efficient and reducing the need for traditional filtration media.

These magnetic filters can be employed to remove solid particles such as sand or scale that accumulate during the extraction and refining process, improving the quality of the petroleum product and extending the life of machinery and equipment.

3. Advantages of Iron Oxide Nanoparticles in Petroleum Separation

The use of iron oxide nanoparticles in petroleum separation processes offers several key benefits:

A. High Efficiency and Selectivity

Due to their large surface area, high magnetic properties, and chemical reactivity, iron oxide nanoparticles are highly efficient in separating oil and water phases, as well as adsorbing toxic metals and organic pollutants. Their ability to selectively interact with specific molecules makes them ideal for targeted separation processes in complex petroleum systems.

B. Easy Recovery and Reusability

Iron oxide nanoparticles are easily recoverable through the use of magnetic fields, which eliminates the need for costly filtration systems or chemicals. This allows for the reuse of the nanoparticles in multiple cycles, reducing both operational costs and environmental impact.

C. Environmental Sustainability

Iron oxide nanoparticles can significantly reduce the use of hazardous chemicals in the petroleum separation process. Traditional oil-water separation often requires the use of chemical agents like surfactants or coalescing agents, which can be harmful to the environment. In contrast, the magnetic recovery of iron oxide nanoparticles minimizes waste generation and helps ensure that the separation process is more sustainable.

D. Cost-Effectiveness

Iron oxide nanoparticles are relatively inexpensive to produce and can be used in large-scale industrial applications. Their ability to improve the efficiency of separation processes, reduce waste, and minimize the need for chemical additives results in cost savings for petroleum operators.

4. Challenges and Limitations

While iron oxide nanoparticles hold great promise for enhancing separation processes in the petroleum industry, there are some challenges to their widespread adoption:

A. Scaling Up Production

Manufacturing large quantities of high-quality iron oxide nanoparticles that are uniform in size and shape can be challenging. Additionally, ensuring their stability in harsh industrial conditions (e.g., high temperatures, pressure, and acidic/basic environments) requires further optimization.

B. Environmental and Health Concerns

As with all nanomaterials, the potential environmental and health impacts of iron oxide nanoparticles need to be carefully studied. Although iron oxide is generally considered non-toxic, their behavior in the environment, especially when released into water systems, requires further investigation to ensure that there are no unintended consequences.

C. Cost of Integration

Integrating iron oxide nanoparticles into existing separation systems and processes may require initial investment in new technologies or infrastructure. However, the long-term benefits in terms of efficiency and cost savings often outweigh these initial costs.

5. Future Directions and Research

Ongoing research is focused on improving the efficiency and sustainability of iron oxide nanoparticles in petroleum applications. Innovations may include:

- Functionalization of nanoparticles to enhance their selectivity and stability in specific separation tasks.

- Hybrid materials, combining iron oxide with other nanomaterials, to improve performance in extreme conditions.

- Development of eco-friendly production methods to minimize the environmental impact of nanoparticle synthesis.

6. Conclusion

Iron oxide nanoparticles are a promising tool for enhancing separation processes in the petroleum industry, offering solutions for oil-water separation, heavy metal removal, demulsification, and magnetic filtration. Their high efficiency, ease of recovery, and environmental sustainability make them an attractive option for improving both the cost-effectiveness and environmental performance of petroleum operations. As research advances and challenges are addressed, iron oxide nanoparticles are poised to play an even more significant role in transforming the way the petroleum industry handles complex separation tasks.