The Future of Materials: Graphene Reinforced Polymer Composites

The world of material science is evolving at a rapid pace, and one of the most promising advancements is the integration of graphene into polymer composites. Graphene-reinforced polymer composites are poised to revolutionize industries by enhancing the properties of polymers, making them stronger, lighter, and more versatile. In this article, we explore how graphene, a one-atom-thick material with exceptional properties, is shaping the future of materials.

What is Graphene?

Graphene is a two-dimensional structure made up of carbon atoms arranged in a honeycomb lattice. Since its discovery, it has garnered widespread attention due to its remarkable properties: it’s incredibly strong (about 200 times stronger than steel), lightweight, conductive, and flexible. These attributes make graphene a prime candidate for enhancing various materials, particularly polymers.

Polymer Composites: A Strong Foundation

Polymers are a group of materials known for their flexibility, durability, and lightweight nature. However, their mechanical strength and thermal properties can sometimes be limiting in demanding applications. This is where graphene-enhanced polymers come into play. When combined with graphene, polymer composites gain significant improvements in strength, electrical conductivity, and heat resistance, making them suitable for high-performance applications across various sectors.

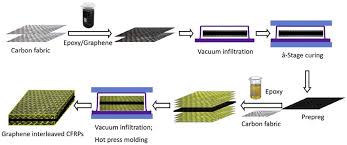

How Graphene Reinforces Polymer Composites

Incorporating graphene nanopowder into polymer matrices can lead to a significant enhancement in the properties of the composite. Graphene’s high surface area and excellent mechanical strength provide reinforcement at the molecular level. This integration results in several key benefits:

- Increased Strength: Graphene’s remarkable tensile strength improves the mechanical properties of polymer composites, making them more durable and resistant to wear and tear.

- Lightweight: Despite the added strength, graphene is extremely light. This makes graphene-reinforced composites ideal for industries where weight reduction is critical, such as aerospace and automotive sectors.

- Thermal and Electrical Conductivity: Graphene is an excellent conductor of both heat and electricity. When added to polymers, it transforms these materials into highly conductive composites, opening up new possibilities in electronics, sensors, and energy storage applications.

- Enhanced Durability: Graphene can improve the resistance of polymer composites to environmental factors like UV radiation, chemical exposure, and temperature extremes, increasing their longevity in outdoor and industrial settings.

Applications of Graphene Reinforced Polymer Composites

The integration of graphene into polymers is already showing promise in a variety of industries:

- Aerospace: Graphene-enhanced polymer composites are being explored for use in aircraft components. Their light weight and strength help reduce fuel consumption while maintaining structural integrity.

- Automotive: Car manufacturers are increasingly using graphene-reinforced composites to reduce vehicle weight, which contributes to improved fuel efficiency and performance. Additionally, these composites can improve the longevity and safety of automotive components.

- Electronics: The conductivity of graphene makes it an excellent material for use in electronics. Graphene-reinforced polymers can be used for flexible electronics, sensors, and even energy storage devices, such as batteries and capacitors.

- Sports Equipment: In the sporting world, graphene composites are being used to create lightweight, high-strength equipment like bicycles, tennis rackets, and golf clubs, offering enhanced performance and durability.

- Medical Devices: Graphene’s biocompatibility and strength make it suitable for medical applications such as prosthetics, implants, and drug delivery systems.

The Role of Nanomaterial Powder

Graphene nanopowder plays a crucial role in the development of graphene-reinforced polymer composites. The powder form of graphene allows for easy dispersion in the polymer matrix, ensuring uniform reinforcement. The fine particle size of graphene nanopowder increases its surface area, making it more effective at enhancing the properties of the polymer.

The use of nanomaterials is a significant advancement in material science, as they allow for fine-tuning of material properties at the molecular or atomic level. Nanomaterials like graphene can improve properties that are otherwise difficult to achieve with traditional materials.

Challenges and Future Prospects

While the potential of graphene-reinforced polymer composites is immense, there are still challenges to overcome. One of the major hurdles is the cost of producing high-quality graphene in large quantities. Additionally, achieving uniform dispersion of graphene in the polymer matrix remains a key challenge for manufacturers.

However, advancements in graphene production methods and the development of more efficient processing techniques are expected to drive down costs and improve the scalability of graphene-reinforced polymers. As research and development continue, we can expect to see more widespread adoption of these materials across a range of industries.

Conclusion

Graphene-reinforced polymer composites are transforming the landscape of materials science. With their enhanced strength, lightweight properties, conductivity, and durability, these advanced materials are opening up new possibilities for innovation in aerospace, automotive, electronics, sports, and beyond. As the production of graphene continues to evolve and nanotechnology advances, the future of graphene composites looks incredibly promising. The integration of graphene into polymer matrices will undoubtedly play a pivotal role in the development of next-generation materials, propelling industries toward more sustainable, efficient, and high-performance solutions.