Simulation and Modeling of Material Properties

In the field of materials science and engineering, understanding and predicting the behavior of materials under various conditions is essential for designing and manufacturing new products. Simulation and modeling of material properties have become indispensable tools in this process, enabling researchers and engineers to predict how materials will perform without the need for extensive and expensive physical testing. This article delves into the significance of simulation and modeling in the study of material properties, the types of models used, and the advancements in computational techniques that have enhanced the accuracy and efficiency of material design.

1. Introduction to Simulation and Modeling in Material Science

Simulation and modeling refer to the use of computational methods to represent the behavior of materials under different conditions, such as stress, temperature, pressure, and chemical environments. These techniques help predict material properties like strength, elasticity, thermal conductivity, and corrosion resistance, among others. By understanding these properties, engineers can design materials and products that meet specific performance criteria.

The traditional approach to material testing involves physical experimentation, but it can be time-consuming and costly. Simulation and modeling provide an alternative by offering insights into material behavior at the molecular, atomic, and macroscopic levels. These techniques can also be used to design new materials, optimize manufacturing processes, and assess the environmental impact of different materials.

2. Types of Simulation and Modeling Techniques

Several computational methods are used to simulate and model material properties. These techniques can be broadly classified into the following categories:

A. Molecular Dynamics (MD) Simulations

Molecular dynamics simulations are a widely used computational technique for studying the behavior of materials at the atomic and molecular scale. In this method, the positions and velocities of atoms are calculated over time by solving the equations of motion. MD simulations provide insights into how atomic interactions contribute to material properties such as strength, elasticity, and thermal conductivity.

- Applications: MD simulations are often used to study the properties of polymers, nanomaterials, metals, and alloys. They help to understand atomic interactions, phase transitions, diffusion processes, and the effects of temperature and pressure on material behavior.

B. Finite Element Method (FEM) Simulations

The Finite Element Method is a powerful computational technique used to solve complex structural and mechanical problems. FEM divides a material or structure into smaller elements and analyzes the behavior of each element under specific conditions. The results are then aggregated to predict the overall behavior of the material or system.

- Applications: FEM is commonly used to predict the mechanical properties of materials, such as stress, strain, and deformation. It is also useful for simulating thermal and fluid dynamics, helping to optimize material designs for specific applications like aerospace, automotive, and civil engineering.

C. Density Functional Theory (DFT) Simulations

Density Functional Theory is a quantum mechanical method used to calculate the electronic structure of materials. DFT allows researchers to study the behavior of electrons within atoms and molecules, which plays a crucial role in determining the material’s properties such as conductivity, magnetism, and optical characteristics.

- Applications: DFT simulations are particularly useful for designing new materials, such as semiconductors, superconductors, and catalysts, by predicting how they will behave under different conditions. This method helps in understanding how atomic-level interactions influence macroscopic material properties.

D. Monte Carlo (MC) Simulations

Monte Carlo simulations use random sampling methods to simulate complex systems and predict the behavior of materials. In this technique, many random configurations are tested, and the average result is used to estimate the material’s properties. MC simulations are often used to model systems with a large number of interacting particles or atoms.

- Applications: MC simulations are commonly applied in the study of phase transitions, diffusion processes, and material failure. They are also used in analyzing the thermodynamic properties of materials and predicting how different factors, such as temperature or pressure, affect the material’s behavior.

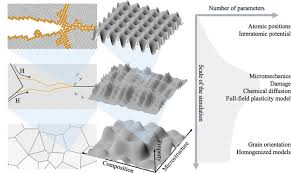

E. Multiscale Modeling

Multiscale modeling combines different computational techniques to study materials at various scales, from the atomic to the macroscopic. This approach provides a more comprehensive understanding of material behavior by linking the microstructure of a material to its macroscopic properties.

- Applications: Multiscale modeling is used in the design of advanced materials such as nanocomposites, biomaterials, and high-performance alloys. It allows for the study of the interactions between different levels of material structure and how these interactions influence material properties at larger scales.

3. Key Material Properties Modeled and Simulated

Simulation and modeling can be used to predict a wide range of material properties that are essential for designing and optimizing materials for specific applications. Some of the key material properties that are commonly modeled and simulated include:

A. Mechanical Properties

- Elasticity and Strength: Simulations can predict how materials deform under stress, including elastic modulus, yield strength, and fracture toughness. This helps in designing materials that can withstand mechanical forces without failure.

- Fatigue and Crack Propagation: Predicting how materials will behave under repeated loading or when cracks form is crucial for applications in aerospace, automotive, and civil engineering.

B. Thermal Properties

- Thermal Conductivity: Simulations help predict how efficiently a material conducts heat, which is important in applications such as heat exchangers, electronic devices, and thermal insulators.

- Thermal Expansion: Modeling material expansion under temperature changes is essential for designing materials that must maintain structural integrity under varying temperature conditions.

C. Electrical and Magnetic Properties

- Conductivity and Resistivity: Materials used in electronics or energy storage must have specific electrical properties. Simulations can predict how materials will conduct or resist the flow of electrical current.

- Magnetic Behavior: For materials used in magnetic applications, such as data storage and sensors, simulations help predict magnetic properties like coercivity and saturation magnetization.

D. Optical Properties

- Absorption and Reflection: Simulation methods can predict how materials interact with light, including how they absorb or reflect specific wavelengths. This is critical for materials used in coatings, lenses, and solar cells.

- Band Gap: For semiconductor materials, simulating the electronic band gap is crucial for determining their electrical conductivity and optical properties.

E. Corrosion and Degradation

- Chemical Stability: Simulations are used to predict how materials will react with environmental factors such as moisture, oxygen, and acids. This helps in designing materials that are resistant to corrosion or degradation.

- Oxidation Behavior: Modeling the oxidation of materials helps predict the long-term performance of materials exposed to high-temperature or reactive environments.

4. Advancements in Computational Techniques

Recent advancements in computational power and algorithms have significantly enhanced the accuracy and efficiency of material simulations. Some of these advancements include:

- High-Performance Computing (HPC): The use of supercomputers and parallel computing has enabled the simulation of larger, more complex systems with higher accuracy. This allows for the modeling of materials with thousands or even millions of atoms or molecules.

- Machine Learning and Artificial Intelligence: Machine learning algorithms are increasingly being applied to materials science to optimize the prediction of material properties. AI can be used to identify patterns in data, predict new materials, and even optimize material designs based on performance criteria.

- Quantum Computing: Quantum computing promises to revolutionize material simulations by enabling calculations of material properties at the quantum level with unprecedented speed and accuracy. Although still in its early stages, quantum computing holds great potential for simulating complex material behaviors and discovering new materials.

5. Applications of Material Simulation and Modeling

Simulation and modeling play a critical role in several industries, including:

- Aerospace and Defense: Predicting the mechanical, thermal, and electrical properties of materials for aircraft and spacecraft is essential for ensuring safety and performance.

- Electronics and Semiconductors: Simulations are used to design materials with specific electrical properties, improving the performance of devices such as transistors, solar cells, and batteries.

- Energy and Sustainability: In energy storage, simulations help design better batteries and supercapacitors, while in renewable energy, they aid in the development of more efficient solar cells and wind turbine materials.

- Automotive Industry: Material modeling is used to develop lightweight, durable materials that improve fuel efficiency and vehicle safety.

6. Conclusion

The simulation and modeling of material properties are indispensable tools in modern materials science and engineering. By leveraging advanced computational techniques such as molecular dynamics, finite element analysis, and density functional theory, researchers can predict and optimize material properties before physical testing. This accelerates the development of new materials, enhances product performance, and reduces costs. As computational power continues to improve, the accuracy and scope of material simulations will expand, offering exciting possibilities for innovation across various industries.