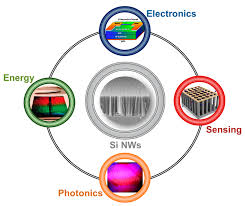

Silicon Nanowires: Synthesis and Application Areas

Silicon nanowires, ultra-thin wire-like structures composed of silicon atoms, have gained substantial attention in the field of nanotechnology due to their unique properties, such as high surface area, excellent electrical conductivity, and flexibility. These characteristics make them suitable for a variety of applications across industries, including electronics, energy storage, sensors, and medical devices. This article explores the synthesis methods of silicon nanowires and their diverse applications.

What Are Silicon Nanowires?

Silicon nanowires (SiNWs) are semiconductor nanostructures with a diameter typically ranging from a few nanometers to several hundred nanometers. Unlike bulk silicon, which is used in conventional electronics, silicon nanowires exhibit novel quantum properties due to their reduced dimensionality, making them valuable for nanoelectronics and other advanced technologies.

These nanowires are characterized by:

- High surface-to-volume ratio

- High electrical and thermal conductivity

- Enhanced mechanical properties

- Quantum confinement effects, which are more pronounced due to their reduced size

The unique attributes of silicon nanowires make them ideal candidates for a wide range of applications in various fields, from energy storage systems to biomedical devices.

Synthesis of Silicon Nanowires

The synthesis of silicon nanowires can be achieved through several techniques, each offering different advantages in terms of scalability, control over size and morphology, and ease of integration into devices.

1. Vapor-Liquid-Solid (VLS) Method

The VLS method is one of the most widely used techniques for the synthesis of silicon nanowires. In this process:

- A silicon precursor, typically silane (SiH₄), is vaporized.

- The vapor is exposed to a catalytic metal, such as gold (Au), which forms a liquid alloy.

- Silicon atoms then precipitate from the vapor, forming nanowires with a controlled diameter.

Advantages: This method allows for high control over the nanowire diameter and length and is scalable for industrial production.

2. Electrochemical Deposition

Electrochemical deposition involves using an electrochemical cell where a silicon-containing electrolyte is deposited onto a substrate in the presence of an electric current. This method enables precise control over the nanowire growth, making it ideal for applications that require uniformity and scalability.

Advantages: This technique is often used for creating vertically aligned silicon nanowires and can be integrated with other microfabrication processes.

3. Laser Ablation

In laser ablation, a high-powered laser is used to vaporize a silicon target, and the vaporized material is then allowed to condense into nanowires. This technique can be used to produce high-purity nanowires and is often employed in laboratory-scale experiments.

Advantages: It allows for the rapid production of high-quality silicon nanowires.

4. Chemical Vapor Deposition (CVD)

In CVD, a silicon precursor gas is passed over a heated substrate, where it decomposes, and silicon is deposited as nanowires. This method is particularly advantageous for producing high-purity silicon nanowires in a controlled environment.

Advantages: CVD provides good control over the structure and morphology of the nanowires.

Applications of Silicon Nanowires

Silicon nanowires are being explored for a wide range of applications due to their versatile properties. Below are some of the most significant fields where they are showing potential:

1. Energy Storage and Conversion

Silicon nanowires have found applications in batteries and supercapacitors due to their high surface area and enhanced electrochemical performance.

- Lithium-Ion Batteries: Silicon is an excellent material for anodes in lithium-ion batteries, but it tends to expand during cycling, leading to capacity loss. Silicon nanowires, due to their nanostructure, can accommodate expansion, leading to improved cycle stability and capacity retention.

- Supercapacitors: Silicon nanowires can increase the overall surface area and charge storage capacity, enhancing the performance of supercapacitors.

2. Nanoelectronics

Silicon nanowires are being studied for use in field-effect transistors (FETs), solar cells, and logic circuits. Their high surface-to-volume ratio and conductivity make them ideal for smaller, more efficient electronic components.

- Transistors: Silicon nanowire-based transistors can potentially replace traditional silicon-based devices in high-performance computing and nanoelectronics.

- Photovoltaic Devices: In solar cells, silicon nanowires enhance light absorption, improving the efficiency of solar energy conversion.

3. Sensors and Biosensors

The high surface-to-volume ratio of silicon nanowires also makes them attractive for use in sensors and biosensors. These devices can be utilized for chemical detection, environmental monitoring, and even in medical diagnostics.

- Chemical Sensors: Silicon nanowires can detect gases, chemicals, and other substances at low concentrations, making them highly sensitive.

- Biosensors: In the medical field, silicon nanowires can be used in biosensors for detecting specific biomolecules or pathogens, providing early diagnosis and monitoring.

4. Biomedical Applications

Silicon nanowires hold significant promise in drug delivery, gene therapy, and tissue engineering. Their biocompatibility, combined with their unique electrical and mechanical properties, allows them to be integrated with biological systems.

- Drug Delivery: Nanowires can be used to deliver drugs more effectively to targeted areas in the body, enhancing the precision of treatment.

- Gene Therapy: Silicon nanowires are being investigated as a potential gene delivery system due to their ability to carry and release genetic material into cells efficiently.

5. Thermal Management

The excellent thermal conductivity of silicon nanowires makes them suitable for use in thermal management systems, particularly in microelectronics and optical devices where heat dissipation is a critical concern.

- Thermal Conductivity: Silicon nanowires can help reduce overheating in electronic devices, improving their reliability and performance.

6. Optical Applications

Due to their unique optical properties, silicon nanowires can be utilized in applications involving light emission and optical waveguides. They can be integrated into light-emitting diodes (LEDs) and optical sensors.

- LEDs: The ability of silicon nanowires to emit light makes them suitable for next-generation LEDs with improved efficiency.

- Photodetectors: Silicon nanowires can also be used in photodetectors, which are critical in communication and imaging technologies.

Challenges and Future Outlook

While silicon nanowires offer tremendous potential, there are several challenges that need to be addressed for widespread adoption:

- Scalability: Producing silicon nanowires in large quantities while maintaining uniform quality remains a significant challenge.

- Integration: Integrating silicon nanowires into existing technologies and industrial processes is another hurdle that must be overcome for commercial applications.

- Cost: The high cost of production techniques such as chemical vapor deposition and laser ablation needs to be reduced to make silicon nanowires more cost-effective for large-scale use.

Despite these challenges, the future of silicon nanowires looks promising. Ongoing research is focused on improving synthesis methods, optimizing the performance of nanowire-based devices, and exploring new application areas. As technology advances, silicon nanowires are poised to become a cornerstone of next-generation electronics, energy storage, and biomedical innovations.

Conclusion

Silicon nanowires are a remarkable material with numerous potential applications across various industries, from energy storage and nanoelectronics to biomedicine and sensors. Their unique properties, including high surface area, excellent conductivity, and mechanical strength, make them invaluable for the development of more efficient and advanced technologies. While challenges remain in scaling up production and reducing costs, the future of silicon nanowires is bright, and ongoing research will continue to unlock new possibilities for these versatile nanostructures.