Porous Metallic Foams as an Electrode for Supercapacitor Applications

Supercapacitors, also known as ultracapacitors, have emerged as one of the most promising energy storage devices due to their high power density, long cycle life, and fast charge-discharge capabilities. One of the key components of supercapacitors is the electrode material, which plays a crucial role in determining their performance. Porous metallic foams have recently gained attention as ideal electrode materials for supercapacitors due to their exceptional properties, including high surface area, high conductivity, and mechanical strength. In this article, we will explore the characteristics, advantages, and potential applications of porous metallic foams in supercapacitor technology.

What Are Porous Metallic Foams?

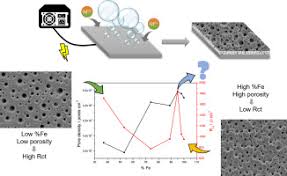

Porous metallic foams are materials that have a porous structure, typically with a high percentage of voids (pores) within the material, creating a sponge-like appearance. They are made from metals or metal alloys and are fabricated through various methods such as powder metallurgy, gas expansion, and direct foaming. The porosity in these foams allows for a large surface area, which is a desirable trait for supercapacitor electrodes, where a high surface area is critical for charge storage.

Some common materials used to make porous metallic foams include nickel (Ni), cobalt (Co), aluminum (Al), titanium (Ti), and copper (Cu). These materials are selected based on factors such as electrical conductivity, mechanical strength, and chemical stability, which are important for the long-term performance of supercapacitors.

Key Properties of Porous Metallic Foams for Supercapacitor Electrodes

Several properties of porous metallic foams make them attractive candidates for supercapacitor electrodes. Some of the most important ones include:

1. High Surface Area

Porous metallic foams have a high specific surface area due to their porous nature, which allows for more electrochemical reactions to take place on the surface. The increased surface area leads to a higher energy storage capacity, making them ideal for supercapacitor applications.

2. Good Electrical Conductivity

Metals, especially those like copper, nickel, and titanium, have high electrical conductivity. This ensures that electrons can flow easily through the material, facilitating efficient charge-discharge cycles in the supercapacitor. The conductivity of porous metallic foams is comparable to that of solid metals, which is crucial for high-performance energy storage devices.

3. Mechanical Strength

The mechanical properties of porous metallic foams are excellent. They are lightweight but strong, and their foam structure provides them with resilience and durability. These materials can withstand mechanical stress, making them suitable for applications where high cyclic stability is needed.

4. Tailorable Porosity

The porosity of metallic foams can be controlled during fabrication, allowing the structure to be tailored to suit specific applications. The pore size distribution can be adjusted to optimize the electrochemical performance of the electrode material, such as enhancing ion transport and improving electrode-electrolyte interaction.

5. Corrosion Resistance

Many metallic foams, especially those made from titanium and nickel, exhibit high corrosion resistance. This property is important for supercapacitor electrodes, as the material needs to remain stable and perform well in the electrolyte over a long period, even under harsh operating conditions.

Advantages of Porous Metallic Foams as Supercapacitor Electrodes

Using porous metallic foams as electrodes for supercapacitors offers several advantages:

1. Enhanced Charge Storage Capacity

The large surface area and porosity of metallic foams enable them to store more charge compared to traditional electrodes. This results in higher capacitance and improved energy storage capabilities for supercapacitors, allowing them to store more energy without compromising on performance.

2. Improved Power Density

Due to the high electrical conductivity of metals, the power density of supercapacitors with metallic foam electrodes is significantly improved. This enables fast charging and discharging, which is a critical feature for many applications requiring rapid energy release, such as electric vehicles (EVs), consumer electronics, and smart grids.

3. Long Cycle Life

The mechanical strength and corrosion resistance of metallic foams contribute to their long cycle life. Supercapacitors with metallic foam electrodes can endure many charge-discharge cycles without significant degradation of performance, making them highly reliable for long-term applications.

4. Customization of Performance

The ability to tailor the pore structure and material composition allows for the optimization of the supercapacitor’s performance. For example, by choosing different metal alloys or modifying the porosity, the supercapacitor’s energy density, power density, and operating voltage can be fine-tuned to meet specific application requirements.

5. Lightweight Nature

Porous metallic foams are lightweight, which is essential for applications like electric vehicles, where reducing the overall weight of energy storage systems can improve overall efficiency and driving range.

Applications of Porous Metallic Foams in Supercapacitors

The exceptional properties of porous metallic foams make them suitable for a wide range of applications in energy storage systems, particularly in supercapacitors. Some of the key areas of application include:

1. Electric Vehicles (EVs)

In electric vehicles, supercapacitors are used to provide rapid bursts of power, especially for applications like acceleration and regenerative braking. Porous metallic foams make an excellent choice for supercapacitor electrodes in EVs due to their high power density and long cycle life, which are crucial for maintaining vehicle performance and durability.

2. Consumer Electronics

Supercapacitors are increasingly being used in consumer electronics like smartphones, laptops, and wearable devices to provide quick energy bursts and extend battery life. The high charge-discharge efficiency of porous metallic foam-based electrodes enhances the performance of supercapacitors in these devices, making them more efficient and longer-lasting.

3. Energy Storage Systems

In grid energy storage systems, supercapacitors are used to store and release energy rapidly, supporting renewable energy sources like solar and wind power. Porous metallic foam electrodes help enhance the energy storage capacity and cycling stability of these systems, enabling them to support intermittent energy sources effectively.

4. Military and Aerospace Applications

Supercapacitors with metallic foam electrodes are also finding applications in military and aerospace industries, where reliable, high-power energy storage is essential. The high energy density and mechanical robustness of porous metallic foams make them suitable for these demanding environments, where weight and performance are critical.

Challenges and Future Directions

While porous metallic foams offer numerous benefits, there are still challenges to overcome. These include the cost of fabrication, scalability of production, and ensuring the uniformity of porosity in large-scale applications. Future research is focused on improving fabrication techniques, exploring new metal alloys, and further optimizing the pore structure to enhance the performance of supercapacitors.

Conclusion

Porous metallic foams are a promising material for supercapacitor electrodes due to their high surface area, excellent electrical conductivity, mechanical strength, and corrosion resistance. Their ability to enhance charge storage capacity, power density, and cycle life makes them ideal for applications in electric vehicles, consumer electronics, grid energy storage, and aerospace. As research continues to improve the production and performance of porous metallic foams, we can expect to see their increasing use in next-generation supercapacitors that will drive innovation across various industries.