Nitrogen-Containing Graphene Ribbons: Properties, Synthesis, and Applications

Graphene—a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice—has garnered widespread attention for its exceptional electrical conductivity, mechanical strength, and thermal properties. By doping graphene with various elements, researchers have been able to further tailor its properties to suit a broader range of applications. One such modification is the incorporation of nitrogen atoms into the graphene structure, leading to the creation of nitrogen-containing graphene ribbons (NGRs).

This article delves into the properties, synthesis methods, and applications of nitrogen-doped graphene ribbons, and explores how this material is revolutionizing various industries, including energy storage, electronics, and catalysis.

What Are Nitrogen-Containing Graphene Ribbons?

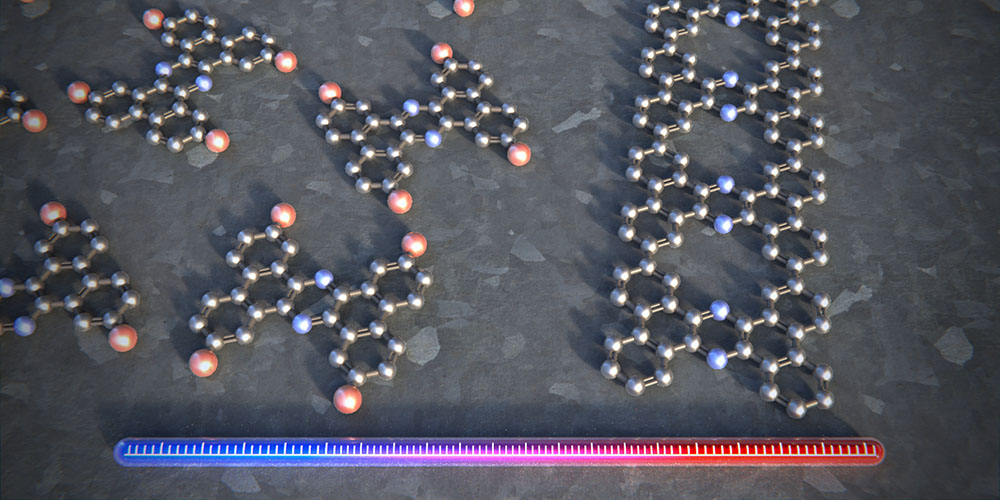

Nitrogen-containing graphene ribbons (NGRs) are graphene sheets with nitrogen atoms integrated into their carbon lattice. This nitrogen doping introduces functional groups such as pyrrolic, pyridinic, or quaternary nitrogen, which significantly alter the electronic, chemical, and mechanical properties of graphene.

When these nitrogen-doped graphene structures are synthesized as ribbons—i.e., narrow, elongated graphene strips—this shape provides additional advantages, such as enhanced surface area, edge effects, and confinement of electron flow, all of which contribute to improved material performance in various applications.

Properties of Nitrogen-Containing Graphene Ribbons

The introduction of nitrogen into the graphene lattice imparts several unique properties to the material, making it highly versatile for different technological applications:

1. Improved Electrical Conductivity

The nitrogen atoms can introduce additional charge carriers to the graphene structure, leading to enhanced electrical conductivity. Nitrogen doping can create localized charge density states in the material, which improve electron transport properties. This makes NGRs highly suitable for electronic devices, supercapacitors, and sensors.

2. Enhanced Catalytic Activity

Nitrogen-containing functional groups, such as pyridinic nitrogen, can act as active sites for catalysis. This makes nitrogen-doped graphene ribbons highly efficient for a variety of catalytic reactions, such as oxygen reduction reactions (ORR), hydrogen evolution reactions (HER), and CO2 reduction reactions. Nitrogen doping can enhance the material’s performance in fuel cells and batteries, where catalytic efficiency is crucial.

3. Superior Chemical Reactivity

The presence of nitrogen atoms in the graphene lattice increases the chemical reactivity of the material. This is particularly useful for energy storage devices (like batteries and supercapacitors) and in the environmental remediation industry, where the material can help remove pollutants.

4. High Mechanical Strength

Despite doping, the mechanical properties of nitrogen-doped graphene ribbons remain excellent. The material retains its remarkable strength and flexibility, which makes it ideal for use in composites, flexible electronics, and wearable devices.

5. Magnetic Properties

In some cases, nitrogen doping can induce magnetic behavior in graphene, especially when nitrogen atoms are incorporated into defect sites or on the edges of graphene ribbons. This makes NGRs suitable for spintronics and other applications that rely on the manipulation of electron spin.

Synthesis of Nitrogen-Containing Graphene Ribbons

Several methods can be used to synthesize nitrogen-doped graphene ribbons, each offering different levels of control over the doping process, morphology, and overall material quality. Below are the main approaches:

1. Chemical Vapor Deposition (CVD)

One of the most popular methods for synthesizing nitrogen-doped graphene ribbons is CVD. In this process, a carbon source (such as methane) and a nitrogen-containing precursor (such as ammonia or pyridine) are passed over a catalyst, typically a copper or nickel substrate. The carbon source decomposes and forms graphene, while nitrogen atoms are incorporated into the graphene lattice, either during or after the deposition process.

- Advantages: High-quality graphene ribbons can be produced with precise control over the nitrogen doping level.

- Challenges: This process can be expensive and requires specialized equipment.

2. Hydrothermal and Solvothermal Methods

Hydrothermal synthesis involves the reaction of organic carbon sources (like glucose or citric acid) with nitrogen sources (like urea or ammonium nitrate) in an aqueous solution under high temperature and pressure. This method can be scaled up for larger production volumes and can produce graphene ribbons with nitrogen-doped functional groups.

- Advantages: Simpler and cost-effective compared to CVD.

- Challenges: Less control over the size and uniformity of the graphene ribbons.

3. Exfoliation of Nitrogen-Doped Graphene Oxide

Graphene oxide (GO) can be treated with nitrogen-containing compounds such as ammonia or urea to introduce nitrogen functional groups. This can be followed by a chemical reduction or thermal treatment to exfoliate the graphene oxide into nitrogen-doped graphene. The final material can then be processed into graphene ribbons by controlled cutting or exfoliation techniques.

- Advantages: Relatively simple and inexpensive.

- Challenges: The quality of the graphene ribbons may be lower compared to those produced by CVD.

4. Laser Ablation and Plasma-Assisted Methods

Laser ablation or plasma-assisted methods can also be employed to create nitrogen-doped graphene ribbons. In these methods, laser irradiation or plasma exposure can induce nitrogen incorporation into the graphene structure by treating graphite or graphene oxide with nitrogen-containing gases.

- Advantages: Can create high-quality, defect-free nitrogen-doped graphene ribbons.

- Challenges: High energy consumption and equipment cost.

Applications of Nitrogen-Containing Graphene Ribbons

Nitrogen-containing graphene ribbons combine the unique properties of graphene with the added benefits of nitrogen doping, leading to several key applications across various industries:

1. Energy Storage and Conversion

- Supercapacitors: The enhanced electrical conductivity and high surface area of nitrogen-doped graphene ribbons make them excellent candidates for supercapacitors. NGRs can store more energy and provide faster charge/discharge cycles compared to traditional materials.

- Batteries: In lithium-ion and sodium-ion batteries, nitrogen-doped graphene ribbons can serve as both anode and cathode materials, improving charge storage and enhancing cycling stability.

- Fuel Cells: NGRs can serve as catalysts in fuel cells, particularly for the oxygen reduction reaction (ORR), improving the overall efficiency of fuel cell systems.

2. Electronics and Flexible Devices

Due to their high conductivity and mechanical strength, nitrogen-containing graphene ribbons are ideal for use in flexible electronics, such as wearable devices, flexible displays, and bendable sensors. Their combination of electrical performance and structural integrity enables lightweight and durable electronic components.

3. Sensors and Biosensors

The high surface area and tunable chemical properties of nitrogen-doped graphene ribbons make them ideal for chemical sensors and biosensors. These materials can be used for the detection of gases, toxic chemicals, or biological molecules in medical diagnostics, environmental monitoring, and industrial applications.

4. Catalysis

Nitrogen doping enhances the catalytic activity of graphene, making NGRs ideal for applications in energy conversion, fuel production, and environmental remediation. Nitrogen-containing graphene ribbons can act as catalysts for hydrogenation reactions, CO2 reduction, and water splitting.

5. Water Purification

Nitrogen-doped graphene ribbons, due to their hydrophilic nature and high surface area, can be used in water filtration systems, particularly for removing heavy metals, organic pollutants, and pathogens. The enhanced reactivity of nitrogen-doped materials allows them to effectively adsorb contaminants and purify water.

Challenges and Future Prospects

While nitrogen-containing graphene ribbons exhibit numerous benefits, there are still challenges to address:

- Control Over Doping Levels: Achieving uniform nitrogen doping and controlling the type of nitrogen functional group incorporated into the graphene lattice is critical for tuning the material’s properties for specific applications.

- Scalability: Many of the synthesis methods for nitrogen-doped graphene ribbons, particularly CVD, can be expensive and difficult to scale up for industrial production.

- Environmental Impact: The long-term environmental impact of large-scale use of nitrogen-doped graphene is still an area of ongoing research. Ensuring that these materials are biodegradable or non-toxic is essential for their safe integration into industrial processes.

Despite these challenges, the future of nitrogen-containing graphene ribbons is bright. As research progresses, new methods for cost-effective, large-scale synthesis are likely to emerge, making NGRs more accessible for industrial applications.

Conclusion

Nitrogen-containing graphene ribbons are a highly promising class of nanomaterials with extraordinary potential in energy storage, electronics, catalysis, and environmental applications. By combining the remarkable properties of graphene with the benefits of nitrogen doping, NGRs offer enhanced electrical conductivity, catalytic activity, and mechanical strength, making them ideal candidates for a wide array of cutting-edge technologies.

As the field of nanotechnology continues to evolve, nitrogen-doped graphene ribbons are expected to play a key role in shaping the future of industries such as energy, electronics, and environmental sustainability.