Molybdenum Disulfide (MoS2): Properties and Applications

Molybdenum disulfide (MoS₂) is a fascinating compound that has garnered significant attention in various scientific and industrial fields due to its unique properties. As a transition metal dichalcogenide (TMD), MoS₂ exhibits distinct physical, chemical, and electronic characteristics, making it highly suitable for a broad range of applications, from lubrication to electronics and energy storage. This article provides an in-depth look at the properties, synthesis methods, and diverse applications of MoS₂.

1. Introduction to Molybdenum Disulfide (MoS₂)

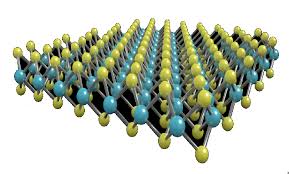

Molybdenum disulfide (MoS₂) is a layered material composed of molybdenum (Mo) atoms sandwiched between two layers of sulfur (S) atoms. It belongs to a group of materials known as transition metal dichalcogenides (TMDs), which share a similar structure but vary in their electronic properties depending on the metal and chalcogen elements used. MoS₂ is one of the most studied TMDs due to its remarkable versatility and unique two-dimensional (2D) properties when reduced to nanoscale thickness.

2. Key Properties of MoS₂

2.1 Structural Properties

- Layered Structure: MoS₂ exhibits a layered crystal structure in which each layer consists of a hexagonal arrangement of Mo atoms between two layers of S atoms. The layers are bound by weak van der Waals forces, allowing them to be easily exfoliated into thin sheets. This feature is similar to graphene, a carbon-based 2D material.

- Exfoliation: Due to the weak interlayer forces, MoS₂ can be exfoliated into monolayers or few-layer sheets, which significantly alters its properties compared to its bulk form.

2.2 Electronic Properties

- Semiconducting Behavior: Bulk MoS₂ is an indirect bandgap semiconductor with a bandgap of around 1.2 eV, which makes it unsuitable for high-efficiency electronic applications. However, when exfoliated to monolayers, MoS₂ exhibits a direct bandgap of approximately 1.8 eV, which allows it to absorb light and emit photons, making it highly promising for optoelectronic devices.

- High Carrier Mobility: MoS₂, especially in its monolayer form, exhibits high electron mobility, making it ideal for high-speed electronic applications.

2.3 Mechanical Properties

- Strong Yet Flexible: MoS₂ is mechanically strong, but its 2D nature allows it to be highly flexible. The monolayer MoS₂ sheets retain their mechanical strength while exhibiting flexibility, which is useful for a variety of applications such as flexible electronics.

2.4 Optical Properties

- Photoluminescence: MoS₂ exhibits strong photoluminescence, especially in its monolayer form, making it a valuable material for optoelectronic applications, including light-emitting diodes (LEDs) and photodetectors.

- Tunable Optical Absorption: The bandgap of MoS₂ is tunable by controlling the number of layers, which allows for modulation of its optical properties. This tunability is important in developing devices that require specific light absorption or emission characteristics.

2.5 Catalytic Properties

- Hydrogen Evolution Reaction (HER): MoS₂ is a promising catalyst for hydrogen production via water splitting. The molybdenum atoms in MoS₂ can serve as active sites for the hydrogen evolution reaction (HER), making it a potential material for sustainable energy applications.

- Electrocatalysis: MoS₂ has shown significant promise in other electrocatalytic applications, such as in fuel cells and batteries.

3. Synthesis Methods of MoS₂

The synthesis of MoS₂ can be achieved through various methods, each of which is chosen based on the desired size, morphology, and application of the material.

3.1 Chemical Vapor Deposition (CVD)

- CVD is one of the most common methods used to grow high-quality MoS₂ monolayers. It involves the decomposition of molybdenum-containing precursors (such as molybdenum hexacarbonyl) in the presence of sulfur-containing gases (such as hydrogen sulfide or sulfur vapor) at elevated temperatures.

- This method allows for the controlled growth of large-area MoS₂ monolayers and is widely used for fabricating electronic and optoelectronic devices.

3.2 Exfoliation Techniques

- Mechanical Exfoliation: Similar to the method used for graphene, MoS₂ can be exfoliated from bulk crystals using mechanical exfoliation techniques, such as the Scotch tape method. This produces few-layer and monolayer MoS₂ flakes that are useful for experimental and device fabrication purposes.

- Liquid-phase Exfoliation: This method involves dispersing MoS₂ powder in a solvent and applying shear forces (such as sonication) to break apart the bulk material into individual nanosheets. This technique is scalable and suitable for mass production of MoS₂ nanomaterials.

3.3 Hydrothermal Synthesis

- Hydrothermal or solvothermal synthesis involves the reaction of molybdenum precursors with sulfur or sulfur-containing compounds in a solvent at high temperature and pressure. This method can produce MoS₂ nanomaterials with tailored morphologies, such as nanoparticles, nanosheets, or nanowires, for specific applications.

4. Applications of MoS₂

The unique combination of electronic, optical, and mechanical properties makes MoS₂ highly versatile and applicable in numerous fields. Below are some of the most significant applications of MoS₂:

4.1 Lubrication and Tribology

- Solid Lubricant: MoS₂ has been widely used as a solid lubricant due to its layered structure, which allows the layers to slide over one another easily. This reduces friction and wear in mechanical systems. It is commonly used in high-temperature and high-pressure environments where traditional liquid lubricants may fail.

- High-Performance Coatings: MoS₂ is often used as a coating for mechanical parts, such as gears, bearings, and aerospace components, to reduce friction and increase the lifespan of these parts.

4.2 Electronics and Optoelectronics

- Transistors and Logic Gates: MoS₂ is being explored for use in field-effect transistors (FETs) and other electronic components due to its semiconducting properties and high carrier mobility in monolayer form. MoS₂-based transistors are smaller, more efficient, and can operate at lower power compared to traditional silicon-based transistors.

- Photodetectors and Light Emitters: The direct bandgap of monolayer MoS₂ makes it ideal for optoelectronic applications, such as photodetectors, LEDs, and light-emitting diodes. MoS₂ is also used in flexible and wearable optoelectronic devices.

4.3 Energy Storage and Conversion

- Batteries: MoS₂ is being studied for use in lithium-ion batteries and sodium-ion batteries due to its high electrical conductivity and structural stability. MoS₂ can improve the performance of these batteries, particularly in terms of charge/discharge efficiency and capacity retention.

- Supercapacitors: MoS₂ is also being explored as an electrode material in supercapacitors, where its high surface area and electrical conductivity can help store and release large amounts of energy quickly.

- Hydrogen Production (Water Splitting): As mentioned earlier, MoS₂ is an excellent electrocatalyst for hydrogen evolution, making it a potential material for hydrogen production through water splitting, a key technology for renewable energy.

4.4 Catalysis

- MoS₂ is used as a catalyst in various chemical reactions, particularly in petroleum refining and the production of chemicals. Its catalytic activity in hydrogenation reactions makes it a valuable material in the oil and gas industry.

4.5 Sensing and Detection

- Gas Sensors: MoS₂ has been used in gas sensing applications due to its ability to change its electronic properties when exposed to different gases, such as nitrogen dioxide (NO₂) or hydrogen sulfide (H₂S). This makes MoS₂-based sensors suitable for environmental monitoring and industrial safety.

- Biosensors: MoS₂ can also be functionalized with biomolecules to create highly sensitive biosensors for detecting diseases or monitoring biological reactions.

5. Future Outlook

Molybdenum disulfide (MoS₂) has opened up new possibilities in a wide range of fields, including electronics, energy storage, catalysis, and lubrication. As research continues, the scalability of MoS₂ production methods and its integration into commercial devices will be key to unlocking its full potential. With ongoing advancements in synthesis techniques, MoS₂-based materials could become a cornerstone of future nanotechnology and energy-efficient systems.

In conclusion, MoS₂’s combination of unique properties and versatile applications positions it as one of the most promising materials for future technological innovations across multiple industries.