Mesocarbon Microbeads (MCMB) Graphite Micron Powder for Lithium-Ion Batteries

Introduction

As the world moves towards renewable energy solutions and electric vehicles (EVs), lithium-ion batteries (LIBs) have emerged as the cornerstone of energy storage systems. The search for high-performance materials for LIBs continues to drive advancements in battery technologies. Among these, Mesocarbon Microbeads (MCMB), a type of graphite micron powder, have shown great promise as a key material for anodes in lithium-ion batteries. With their unique properties, MCMB graphite micron powder is revolutionizing the performance of LIBs, contributing to longer-lasting, more efficient, and cost-effective energy storage solutions.

In this article, we will explore the composition, properties, and applications of Mesocarbon Microbeads (MCMB) graphite micron powder, especially in the context of its role in lithium-ion batteries.

1. What are Mesocarbon Microbeads (MCMB)?

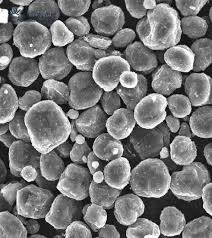

Mesocarbon Microbeads (MCMB) are a specific form of graphite that features spherical, micron-sized particles, which are produced through a thermal mesophase pitch carbonization process. MCMBs are an important form of micron-sized graphite powder, with several distinct structural and functional properties that make them suitable for various high-performance applications, including their use as anode materials in lithium-ion batteries.

Formation of MCMB

MCMB is typically synthesized from mesophase pitch, a precursor material derived from petroleum-based sources. Through a controlled carbonization process, mesophase pitch is heated at high temperatures, resulting in the formation of spherical carbon beads with unique graphitic microstructure. The beads are characterized by their uniform size, porosity, and graphite-like structure.

2. Properties of MCMB Graphite Micron Powder

The properties of MCMB graphite powder play a critical role in its performance as an anode material in lithium-ion batteries. Here are some of the key properties that make MCMB an excellent choice for LIB applications:

a. High Electrical Conductivity

MCMB particles exhibit excellent electrical conductivity due to their graphitic structure. This property is essential for efficient electron transfer during charging and discharging cycles in lithium-ion batteries, which contributes to their high power output and rapid charging times.

b. High Surface Area

The spherical shape of MCMB particles increases the overall surface area compared to other graphite materials. This allows for better interaction between the lithium ions and the anode, enhancing the battery’s energy storage capacity and cycle stability.

c. High Capacity and Long Cycle Life

Due to its graphitic and mesophase structure, MCMB offers higher lithium ion insertion capacity, which translates to higher energy density and longer battery life. This makes MCMB an excellent material for high-performance lithium-ion batteries used in electric vehicles (EVs), smartphones, and renewable energy storage systems.

d. Thermal Stability

MCMB shows strong thermal stability under high temperatures, making it more resistant to thermal degradation during the intense charging and discharging cycles in lithium-ion batteries. This contributes to improved battery safety and longer operational lifespan.

e. Lightweight

MCMB graphite powder is relatively light in weight, making it ideal for applications where weight is a critical factor, such as in electric vehicles and portable electronics. The lightness of the material aids in reducing the overall weight of the battery, enhancing energy density.

3. Advantages of MCMB in Lithium-Ion Batteries

The advantages of using MCMB as an anode material in lithium-ion batteries are numerous and contribute to the advancement of modern energy storage technology. Key benefits include:

a. Improved Electrochemical Performance

MCMB enhances the electrochemical properties of lithium-ion batteries. The spherical shape and well-defined microstructure of MCMB particles allow for faster ion diffusion and better charge retention, ensuring the battery performs efficiently even after many cycles.

b. Enhanced Rate Capability

Because of its high conductivity and efficient charge transfer, MCMB-based anodes exhibit improved rate capability. This means batteries can be charged and discharged quickly without losing significant energy or efficiency, making MCMB ideal for high-power applications like electric vehicles.

c. Better Cycle Stability

MCMB graphite powder has shown outstanding cycle stability compared to traditional graphite anode materials. This is crucial for applications in electric vehicles, laptops, and power tools, where a battery needs to endure hundreds or thousands of charge/discharge cycles without substantial degradation.

d. Cost-Effectiveness

While MCMB may be more expensive than some other forms of graphite, its superior performance and longer lifespan can justify the investment in high-end applications. Additionally, ongoing research and production scaling may reduce the cost of MCMB in the future, making it an increasingly viable option for mainstream energy storage solutions.

4. Applications of MCMB Graphite Micron Powder

MCMB graphite micron powder has found applications across several industries, particularly in the energy storage sector. Below are the primary applications of MCMB in lithium-ion batteries:

a. Electric Vehicles (EVs)

The rise of electric vehicles has greatly benefited from the use of MCMB as an anode material in lithium-ion batteries. MCMB provides EV batteries with high energy density, fast charging capability, and long cycle life, all critical factors for achieving longer driving ranges, shorter charging times, and sustainability in the electric mobility market.

b. Renewable Energy Storage

With the increasing shift toward renewable energy sources like solar and wind, efficient energy storage systems are necessary to ensure continuous power supply. MCMB is used in lithium-ion batteries for grid energy storage and solar energy storage systems, where its long cycle life and high energy density are crucial for reliable energy storage.

c. Portable Electronics

MCMB graphite micron powder is commonly used in lithium-ion batteries powering smartphones, laptops, and wearables. Its excellent charge retention and high capacity make it ideal for powering devices that require compact, long-lasting batteries.

d. Power Tools and Consumer Electronics

MCMB-based batteries are used in cordless power tools and other consumer electronics. The fast charge rates and lightweight properties of MCMB make it well-suited for these applications where quick, efficient power is required.

e. Electric Bicycles (eBikes) and Drones

The growing popularity of eBikes and drones in both recreational and commercial settings has led to an increased demand for efficient, lightweight batteries. MCMB’s high energy density and fast charging properties make it ideal for these applications, providing a powerful, durable battery solution for these devices.

5. Challenges and Future Prospects

While MCMB offers significant advantages for lithium-ion batteries, there are still challenges to address in its development and commercial scaling:

a. Cost and Manufacturing Complexity

The production of MCMB graphite powder can be more costly than other materials due to the complexity of its carbonization process. As demand increases, however, innovations in manufacturing processes may help reduce costs.

b. Potential Improvements in Conductivity

While MCMB already exhibits excellent electrical conductivity, further enhancements may be necessary to optimize it for ultra-high-performance applications, such as in high-speed charging stations and large-scale energy storage systems.

c. Environmental Impact

As with all materials, the environmental impact of MCMB production must be considered. Research into sustainable sources for MCMB production and recycling of MCMB-based batteries will help ensure that their widespread adoption is environmentally responsible.

Conclusion

Mesocarbon Microbeads (MCMB) graphite micron powder is a revolutionary material for lithium-ion batteries, offering enhanced energy density, cycle stability, high conductivity, and thermal stability. With applications ranging from electric vehicles to renewable energy storage systems and portable electronics, MCMB is poised to play a pivotal role in advancing energy storage technologies. As research and manufacturing processes continue to evolve, MCMB-based batteries will likely become more cost-effective and accessible, supporting a wide range of industries in their transition to more sustainable and efficient energy storage solutions.

With its superior properties, MCMB graphite powder is not just a material for today—it is a material for the future of energy storage.