How Tough Graphene Is: Improving the Toughness of Graphene Films

Graphene, often described as a “wonder material,” is a single layer of carbon atoms arranged in a two-dimensional hexagonal lattice. Renowned for its remarkable electrical conductivity, thermal properties, and mechanical strength, graphene has captured the attention of researchers and industries alike. However, despite its many advantages, graphene films and other graphene-based materials face challenges related to their toughness, which refers to the material’s ability to absorb energy and resist fracture under stress.

In this article, we will explore how tough graphene is, the factors that influence its toughness, and the ongoing research to improve the toughness of graphene films for a wider range of applications.

1. Understanding Graphene’s Strength and Toughness

Graphene’s individual atomic structure provides it with exceptional strength. The bonds between carbon atoms in the graphene lattice (known as sp2 bonds) are incredibly strong, making graphene one of the strongest known materials. On a theoretical level, graphene has a tensile strength of approximately 130 gigapascals (GPa), far surpassing that of steel, which has a tensile strength of around 2 GPa.

However, while graphene films exhibit outstanding strength, they can be relatively brittle when it comes to toughness, particularly in bulk form or when produced in large sheets. Toughness refers to a material’s ability to absorb impact or strain energy before breaking. Strength is about how much force a material can withstand without breaking, while toughness considers both strength and the material’s ability to deform without fracturing.

2. Challenges in Improving Graphene Toughness

The main challenge in improving the toughness of graphene films lies in the intrinsic nature of graphene’s atomic structure and how it behaves when scaled up to macroscopic levels. While a single sheet of graphene may exhibit incredible strength, defects, irregularities, and interfaces between layers in graphene films can reduce their ability to absorb energy before breaking.

Here are some factors that influence the toughness of graphene:

- Defects and Imperfections: Vacancies (missing atoms) and structural defects (such as grain boundaries) can create weak points in the graphene film, making it more prone to cracking under stress.

- Interlayer Interactions: In graphene oxide films or multi-layer graphene films, weak interactions between layers can cause delamination or peeling, reducing the material’s overall toughness.

- Size and Geometry: The larger the graphene sheet, the more susceptible it can be to imperfections, which may impact its performance under stress.

3. Strategies for Enhancing Graphene Toughness

To unlock the full potential of graphene, researchers have explored various techniques for improving the toughness of graphene films. Some of these strategies involve altering the material’s structure, introducing composites, and using external agents to improve its resistance to cracking and breakage.

a. Introducing Graphene Composites

One of the most effective ways to improve the toughness of graphene is by combining it with other materials to create composites. These composite materials combine the superior mechanical properties of graphene with the ductility or energy-absorbing characteristics of other substances. Some key graphene composites include:

- Graphene-Polymer Composites: Incorporating graphene into polymer matrices (like epoxy, polyethylene, or polystyrene) can significantly improve toughness. The polymer matrix acts as a matrix that distributes stress, preventing cracks from propagating throughout the graphene layers. These composites are used in various lightweight, high-performance applications, such as automotive and aerospace industries.

- Graphene-Carbon Nanotube (CNT) Composites: Combining graphene with carbon nanotubes results in a hybrid material that inherits the strength of both materials while benefiting from enhanced toughness and flexibility. The CNTs help to distribute strain more effectively, making the material more resistant to fractures.

- Graphene-Ceramic Composites: Adding ceramics like silicon carbide to graphene films enhances their thermal stability and impact resistance, improving toughness without sacrificing strength.

b. Functionalizing Graphene for Toughness Enhancement

Another promising approach is functionalizing graphene by modifying its surface properties. This involves attaching different functional groups to the graphene sheet to improve interlayer bonding or strain tolerance. Methods for functionalizing graphene include:

- Chemical Functionalization: By attaching functional groups (such as hydroxyl or amine groups) to the graphene surface, researchers can improve the adhesion between graphene layers or between graphene and other materials in composite structures. This can prevent delamination, enhance the toughness, and improve the interfacial strength between layers.

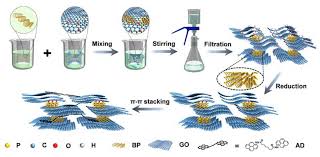

- Graphene Oxide Reduction: Graphene oxide (GO) is a precursor to graphene that can be reduced to graphene through chemical or thermal treatments. Reduced graphene oxide (rGO) films exhibit improved mechanical properties and enhanced toughness, as the reduction process restores some of the material’s intrinsic strength while preserving its flexibility.

c. Using Crosslinking and Bonding Networks

- Crosslinking refers to the creation of chemical bonds between polymer chains or graphene sheets, forming a more three-dimensional network. By using crosslinking agents in graphene-based composites, the elasticity and toughness of the material can be enhanced, making it more capable of absorbing and dissipating energy without breaking.

- Hybrid Networks: Hybridizing graphene with conductive polymers like polypyrrole or polyaniline can lead to the creation of a flexible and stretchable material that retains high toughness due to the interplay between the polymer’s flexibility and graphene’s strength.

d. Nanostructuring Graphene Films

Nanostructuring involves altering the structure of graphene at the nanoscale level to improve its mechanical performance. By patterning graphene or incorporating nanodots or nanoparticles into the graphene matrix, the microstructure can be engineered to increase its resilience to stress.

- Self-healing Graphene Films: Researchers are working on self-healing graphene films, which incorporate nanoparticles or microscopic networks that can heal cracks or damages in the material when subjected to stress. This self-repair capability is a groundbreaking approach to improving the longevity and toughness of graphene films.

4. Real-World Applications of Toughened Graphene Films

Improving the toughness of graphene films unlocks a wide range of potential applications across various industries, including:

- Flexible Electronics: Graphene films with enhanced toughness are ideal for flexible electronics, where materials need to bend and withstand mechanical stress without breaking. Applications include wearable devices, smart textiles, and flexible displays.

- Energy Storage Devices: In supercapacitors and batteries, toughened graphene films can enhance the mechanical stability of electrodes, improving charge cycles and overall performance.

- Composite Materials: Toughened graphene composites are being utilized in lightweight armor, automotive parts, and aerospace materials, offering superior strength, flexibility, and durability.

- Medical Devices: Graphene-based materials with improved toughness can be used in the creation of biocompatible implants and prosthetics, where the combination of strength and flexibility is crucial.

5. Conclusion

Graphene is undoubtedly one of the strongest materials known to humanity, but its brittleness when used in large-scale applications has posed a significant challenge. By utilizing various strategies such as creating graphene composites, functionalizing graphene, and nanostructuring graphene films, researchers are making great strides in enhancing its toughness. As these advancements continue, graphene’s potential to revolutionize fields such as electronics, energy storage, medicine, and manufacturing will be fully realized, making it a truly transformational material for the future.