How Graphene Can Be Used in Polymeric Applications

Introduction

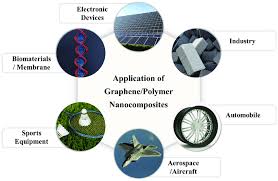

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has emerged as one of the most revolutionary materials of the 21st century. Due to its exceptional properties — including high electrical conductivity, mechanical strength, thermal conductivity, and lightweight nature — graphene is being incorporated into a wide range of industries. One of the most promising applications of graphene is in polymeric materials, where it enhances the properties of polymers for a variety of uses in industries like automotive, aerospace, electronics, and healthcare.

In this article, we will explore how graphene can be used in polymeric applications, including its effects on mechanical performance, conductivity, and other key characteristics that make polymer-graphene composites highly versatile.

1. What Is Graphene and Why Is It Important for Polymeric Applications?

Graphene is a two-dimensional material made of a single layer of carbon atoms, and it possesses unique properties that have the potential to revolutionize a wide array of industries. Some of these properties include:

- High tensile strength: Graphene is incredibly strong, yet lightweight.

- Electrical conductivity: It conducts electricity more efficiently than copper.

- Thermal conductivity: It dissipates heat efficiently.

- Flexibility and stretchability: Despite its strength, graphene can be incorporated into flexible composites.

In polymeric applications, graphene is often used as a filler or reinforcement to improve the polymer’s inherent properties, making it stronger, more durable, and more functional. The combination of graphene and polymer matrices can result in graphene-enhanced polymers, or polymer-graphene composites, with significant performance improvements.

2. Graphene in Polymers: How It Enhances Properties

a. Mechanical Strength

One of the most remarkable features of graphene is its extraordinary tensile strength, which is more than 100 times greater than that of steel. When graphene is added to polymers, it reinforces the polymer matrix, resulting in a significant improvement in its mechanical properties. Graphene can enhance the strength, stiffness, and toughness of polymers without adding significant weight, which is especially important in industries like aerospace, automotive, and construction.

Example applications:

- Lightweight, high-strength materials: Used in automotive body parts, aerospace components, and structural materials that require a balance of strength and lightness.

b. Electrical Conductivity

Polymers are typically insulating materials, which can be a limitation in various electronic applications. Graphene, however, is an excellent conductor of electricity. When incorporated into a polymer matrix, graphene can transform the material into a conductive composite, allowing polymers to be used in flexible electronics, printed circuits, and smart textiles. This property makes graphene-filled polymers ideal for sensors, antistatic coatings, and electromagnetic interference (EMI) shielding.

Example applications:

- Flexible circuits for wearable electronics.

- Antistatic coatings for packaging materials.

- Sensors and batteries for energy storage applications.

c. Thermal Conductivity

Graphene has exceptional thermal conductivity, meaning it can dissipate heat more efficiently than many metals. By incorporating graphene into polymers, the resulting composite materials exhibit improved heat dissipation properties. This is particularly useful in industries where overheating can be a major concern, such as in electronic devices, automotive components, and thermal management systems.

Example applications:

- Heat-resistant coatings for electronics and automotive components.

- Thermal management solutions in batteries, where efficient heat dissipation is crucial for performance and safety.

d. Barrier Properties

Graphene has an extremely low permeability to gases and liquids. When added to polymers, graphene can enhance the barrier properties of the material, making it ideal for packaging applications where protection from moisture, oxygen, or other environmental factors is important. This is particularly beneficial for food packaging, pharmaceuticals, and biomedical applications, where long shelf life and protective barriers are critical.

Example applications:

- Packaging materials for food and beverages.

- Biomedical packaging for drug delivery systems.

- Barrier films for electronic devices to protect from moisture.

3. Types of Polymers Used with Graphene

Graphene can be incorporated into a wide variety of polymers, each offering different benefits depending on the application. Here are some common polymer types used with graphene:

a. Thermoplastics

Thermoplastics are polymers that become soft and moldable when heated and harden when cooled. The addition of graphene to thermoplastics like polypropylene (PP), polymethyl methacrylate (PMMA), polycarbonate (PC), and polyethylene (PE) can significantly improve their mechanical strength, electrical conductivity, and heat resistance.

- Example: Graphene-enhanced polypropylene for lightweight automotive parts.

b. Thermosetting Polymers

Unlike thermoplastics, thermosetting polymers harden permanently after being molded. Graphene can enhance the properties of thermosetting polymers like epoxies, polyurethanes, and phenolic resins, which are commonly used in applications requiring high strength and durability.

- Example: Graphene-based epoxies used in aerospace for composite materials that require lightweight, high-strength properties.

c. Elastomers

Elastomers, such as rubber and silicone, can be enhanced with graphene to improve their mechanical properties, conductivity, and wear resistance. This makes graphene-filled elastomers particularly useful in applications like automotive tires, gaskets, and flexible electronics.

- Example: Graphene-enhanced rubber used in high-performance tires.

4. Key Applications of Graphene in Polymeric Materials

a. Automotive Industry

Graphene-reinforced polymers can significantly improve the lightweight and strength of automotive parts, contributing to better fuel efficiency and vehicle performance. The enhanced thermal conductivity also helps manage heat within automotive systems. Common applications include composite body parts, lightweight frames, and high-performance coatings.

b. Aerospace Industry

In aerospace, weight reduction is critical. Graphene-infused polymers can provide the strength required for structural components while keeping weight to a minimum. Additionally, the high thermal conductivity of graphene makes it valuable in engine parts and thermal management systems. Graphene composites also improve the durability and resilience of aerospace materials under extreme conditions.

c. Electronics and Wearables

Graphene-enhanced conductive polymers are ideal for use in flexible electronics, including wearable devices, flexible circuits, and printed sensors. Graphene’s excellent electrical conductivity, combined with the flexibility of polymers, allows for the creation of lightweight, stretchable, and high-performance electronic components.

- Example: Graphene-based sensors in smart clothing for health monitoring.

d. Packaging

Graphene can also be used to improve the barrier properties of polymeric materials, making them ideal for packaging applications. Food packaging, pharmaceutical packaging, and cosmetic containers all benefit from the enhanced moisture resistance, oxygen barrier, and strength that graphene provides.

e. Biomedical Applications

Graphene-enhanced polymers are being explored for biomedical applications such as drug delivery systems, implants, and biosensors. The unique properties of graphene enable biocompatibility, increased surface area for drug interaction, and the ability to conduct electrical signals, which are key in implantable medical devices and biosensing applications.

5. Challenges and Future Directions

While graphene’s potential in polymeric applications is vast, several challenges remain:

a. Dispersion of Graphene

One of the main challenges when incorporating graphene into polymers is ensuring that the graphene is uniformly dispersed throughout the polymer matrix. Poor dispersion can lead to inconsistent properties and reduced performance of the composite material.

b. Production Costs

Although graphene production has become more cost-effective in recent years, it remains relatively expensive compared to other fillers. As production techniques improve and scale up, the costs of incorporating graphene into polymers will likely decrease, making it more accessible for a wider range of applications.

c. Regulatory and Safety Considerations

Given the novel nature of graphene, more research is required to fully understand its long-term effects on health and the environment, particularly in biomedical applications. Regulatory bodies are working to establish standards for the safe use of graphene in various industries.

Conclusion

Graphene is an extraordinary material with immense potential for enhancing the properties of polymers. Its ability to improve mechanical strength, electrical conductivity, thermal performance, and barrier properties makes it a game-changer in a wide variety of industries, from automotive and aerospace to electronics, packaging, and biomedical fields. As research continues and production methods improve, the use of graphene in polymeric applications will likely expand, offering new, advanced materials that are stronger, smarter, and more sustainable.