Holey Graphene: A Promising Graphene Derivative for Advanced Technologies

Graphene, often referred to as the “wonder material,” has sparked immense interest in scientific and technological communities due to its remarkable properties. This single layer of carbon atoms arranged in a two-dimensional lattice exhibits extraordinary strength, conductivity, and flexibility. However, researchers are constantly seeking to push the boundaries of graphene’s potential, and one exciting development in this area is the creation of holey graphene.

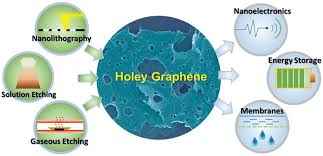

Holey graphene, a derivative of graphene, has gained attention as a promising material for various advanced technologies, including energy storage, water filtration, and environmental remediation. By introducing controlled holes or defects into the graphene lattice, scientists have created a material with unique properties that open up new possibilities across several industries. This article explores the characteristics, production methods, and potential applications of holey graphene.

What is Holey Graphene?

Holey graphene is a modified form of graphene in which nanometer-sized pores or holes are introduced into the structure of the material. These holes disrupt the uniform arrangement of carbon atoms in the graphene sheet, allowing for new properties and functionalities to emerge. The size, shape, and distribution of these holes can be carefully controlled during the manufacturing process, leading to tunable properties for specific applications.

The concept of holey graphene comes from the idea that introducing controlled defects into the perfect graphene lattice could optimize the material’s performance in various domains. These “holes” serve as active sites that increase the surface area and reactivity of the material, giving it advantages over pristine graphene in certain uses.

How is Holey Graphene Produced?

There are several methods to create holey graphene, each focusing on the controlled introduction of defects into the graphene sheet. Some of the most common techniques include:

- Chemical Etching: One of the most widely used methods to produce holey graphene is through chemical etching. In this process, a graphene oxide or reduced graphene oxide sheet is exposed to certain chemicals (such as acids) that selectively etch away parts of the material. The result is a graphene sheet with controlled pores of varying sizes.

- Plasma Treatment: Plasma-based methods can also be used to create holey graphene. This involves using plasma (ionized gas) to bombard graphene with high-energy particles, which creates defects and pores. Plasma treatment is particularly useful for creating highly ordered or uniform hole structures.

- Thermal Treatment: High-temperature processes can be employed to introduce holes into graphene. For example, exposing graphene to a controlled amount of heat in the presence of specific gases can selectively remove carbon atoms, creating pores.

- Laser Irradiation: Laser irradiation is another technique that can be used to create holey graphene. By focusing a laser beam onto graphene, researchers can induce localized damage to the graphene lattice, leading to the formation of holes. The size and distribution of these holes can be fine-tuned by adjusting the laser intensity and exposure time.

- Intercalation with Other Molecules: This method involves inserting specific molecules between the graphene layers, which can cause local disruption in the graphene structure, leading to the formation of holes or pores.

Each of these methods offers unique advantages depending on the intended application and desired properties of the holey graphene.

Advantages of Holey Graphene

The introduction of holes into the graphene structure enhances its properties in several ways, making holey graphene a highly versatile material for a range of applications:

- Increased Surface Area: The creation of pores in the graphene lattice dramatically increases its surface area. This is particularly useful for applications where high surface area is crucial, such as in energy storage devices like batteries and supercapacitors, as well as in adsorption processes like water filtration.

- Improved Porosity for Ion Transport: In applications like energy storage, holey graphene’s porous structure facilitates better ion transport. This allows for faster charge and discharge cycles in batteries and supercapacitors, improving the overall efficiency and performance of these devices.

- Enhanced Reactivity and Catalysis: The holes in the graphene lattice create new active sites for chemical reactions. This makes holey graphene an excellent candidate for catalytic applications, such as in fuel cells or for environmental remediation. The increased reactivity of holey graphene could also enable more efficient chemical processes, reducing energy consumption and waste production.

- Lightweight and Flexible: Like pristine graphene, holey graphene retains the lightweight and flexible characteristics of the original material. This makes it an ideal candidate for flexible electronics and wearable devices, where flexibility, strength, and conductivity are essential.

- Tunable Properties: By controlling the size, shape, and distribution of the holes, researchers can tailor the properties of holey graphene to suit specific applications. This tunability offers significant advantages in areas like sensors, filtration, and electronics, where customization of material properties is key.

Potential Applications of Holey Graphene

Holey graphene’s unique properties open up a wide range of potential applications across various industries. Some of the most promising areas of application include:

- Energy Storage and Supercapacitors: The increased surface area and improved ion transport properties of holey graphene make it an excellent material for use in energy storage devices such as lithium-ion batteries and supercapacitors. By enhancing the efficiency of these devices, holey graphene could lead to batteries that charge faster, last longer, and store more energy.

- Water Filtration and Desalination: The porous structure of holey graphene makes it an ideal candidate for water filtration and desalination processes. The material’s ability to selectively filter molecules means that holey graphene can be used to remove contaminants, salts, and other impurities from water. This has the potential to revolutionize water purification technologies, particularly in areas facing water scarcity.

- Catalysis and Fuel Cells: Holey graphene’s enhanced reactivity and increased surface area make it a promising material for use in catalytic applications, such as fuel cells. It can facilitate more efficient chemical reactions, leading to cleaner energy production and more efficient fuel cell technologies.

- Sensors and Biosensors: The tunable properties of holey graphene, combined with its excellent conductivity, make it highly suitable for sensor applications. Whether for detecting gases, chemicals, or biological markers, holey graphene can be used to create highly sensitive and fast-responding sensors. This could lead to advancements in environmental monitoring, healthcare diagnostics, and security applications.

- Flexible Electronics and Wearable Devices: Holey graphene retains the flexibility and strength of pristine graphene, making it ideal for use in flexible electronics. This includes wearable technology, flexible displays, and advanced circuits that could be used in everything from medical monitoring devices to interactive clothing.

- Environmental Remediation: Due to its high surface area and reactivity, holey graphene can be used to adsorb and remove toxic pollutants from the environment. This includes the removal of heavy metals, organic pollutants, and other hazardous substances from air, water, and soil.

Challenges and Future Directions

While holey graphene offers numerous advantages, there are still challenges that need to be addressed before it can be widely adopted in commercial applications:

- Scalability: Producing holey graphene on a large scale while maintaining consistent quality and control over the properties of the material remains a challenge. Efforts to develop scalable and cost-effective manufacturing processes are ongoing.

- Cost: The production of holey graphene, particularly using advanced methods like laser irradiation or plasma treatment, can be expensive. Reducing the production cost while preserving the material’s properties is a key focus for researchers.

- Durability: Although holey graphene has enhanced properties, the introduction of holes may also lead to decreased mechanical strength in some cases. Ensuring that holey graphene maintains its durability under stress is crucial for its widespread use.

Conclusion

Holey graphene represents a promising advancement in graphene-based materials, offering a unique combination of properties that can be tailored for a variety of applications. With its enhanced surface area, improved porosity, increased reactivity, and flexibility, holey graphene has the potential to revolutionize industries ranging from energy storage and water filtration to catalysis and environmental remediation. While challenges remain in scaling production and reducing costs, ongoing research and innovation suggest that holey graphene could play a central role in the next generation of advanced materials and technologies. As the material continues to evolve, its potential applications are only expected to grow, offering exciting possibilities for both industry and society.