Graphite Nanoparticles and Nanopowder: Transforming Material Science

Graphite nanoparticles and nanopowders are revolutionizing material science with their exceptional properties and versatile applications. Derived from natural graphite, these nanoscale materials exhibit unique mechanical, thermal, and electrical characteristics, making them essential in industries ranging from energy storage to electronics and advanced manufacturing.

What Are Graphite Nanoparticles and Nanopowder?

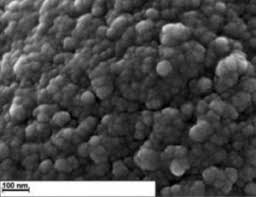

Graphite nanoparticles are extremely small particles of graphite, typically less than 100 nanometers in size. Nanopowder refers to a fine, powdered form of these nanoparticles. Due to their nanoscale dimensions, these materials possess high surface area, enhanced reactivity, and superior conductivity compared to bulk graphite.

Properties of Graphite Nanoparticles and Nanopowder

- High Electrical Conductivity:

- Excellent conductivity makes these materials ideal for use in batteries, supercapacitors, and conductive inks.

- Thermal Stability:

- Exceptional thermal resistance enables their application in high-temperature environments.

- Lightweight and Strong:

- Their low density and high strength make them suitable for composite materials.

- Chemical Stability:

- Resistance to chemical degradation ensures durability in demanding conditions.

- High Surface Area:

- Enhanced surface area improves reactivity and performance in catalysis and adsorption applications.

Applications of Graphite Nanoparticles and Nanopowder

- Energy Storage:

- Used in lithium-ion batteries and supercapacitors to enhance energy density and cycling stability.

- Electronics:

- Graphite nanopowder is integrated into conductive inks and coatings for flexible and wearable electronics.

- Advanced Composites:

- Reinforces polymers and metals, creating lightweight, high-strength materials for aerospace and automotive industries.

- Lubricants:

- Acts as a solid lubricant in high-performance applications, reducing wear and friction.

- Thermal Management:

- Utilized in heat sinks and thermal interface materials for efficient heat dissipation.

- Catalysis:

- Serves as a catalyst or catalyst support in chemical reactions due to its high surface area.

- Water Purification:

- Nanopowders are employed in filters and membranes to remove contaminants effectively.

Advantages of Graphite Nanoparticles and Nanopowder

- Versatility:

- Applicable in a wide range of industries and technologies.

- Cost-Effective:

- Sourced from natural graphite, making them more affordable than synthetic alternatives.

- Environmentally Friendly:

- Potential for use in sustainable energy and green technologies.

- Scalable Production:

- Advanced manufacturing techniques enable large-scale production to meet industrial demands.

Challenges in Using Graphite Nanoparticles

- Aggregation:

- Tendency of nanoparticles to clump together can reduce their effectiveness.

- Dispersion:

- Achieving uniform dispersion in composites and other matrices requires advanced techniques.

- Cost of Processing:

- While raw materials are inexpensive, processing them into usable nanopowders can add to costs.

- Health and Safety:

- Ensuring safe handling and minimizing potential risks to workers and the environment are critical.

Future Prospects

- Energy Innovations:

- Continued research into enhancing battery performance and creating next-generation energy storage solutions.

- Smart Materials:

- Integration into smart materials for responsive and adaptive technologies.

- Green Manufacturing:

- Utilizing graphite nanopowders in eco-friendly production processes and sustainable technologies.

- Medical Applications:

- Exploring biocompatibility for potential use in drug delivery systems and medical devices.

Conclusion

Graphite nanoparticles and nanopowders are reshaping industries with their unique properties and broad applications. As research and technology advance, their role in energy, electronics, and sustainable manufacturing will only grow. By addressing challenges such as dispersion and scalability, these materials hold the promise to drive innovation across diverse sectors, making them indispensable to the future of material science.