Graphene Aerogel: Applications and Properties

Graphene, the remarkable two-dimensional carbon material composed of a single layer of carbon atoms arranged in a honeycomb lattice, has sparked immense interest across various scientific disciplines due to its exceptional electrical, mechanical, and thermal properties. When this extraordinary material is turned into an aerogel, it takes on even more exciting characteristics that broaden its potential applications. Graphene aerogels are lightweight, highly porous materials with outstanding mechanical strength, electrical conductivity, and thermal properties, making them suitable for a wide range of applications from energy storage to environmental cleanup and aerospace engineering.

In this article, we explore the properties, production methods, and various applications of graphene aerogels, as well as the future prospects of this versatile material.

What is Graphene Aerogel?

A graphene aerogel is a lightweight, highly porous material derived from graphene that retains all the exceptional properties of graphene but with added versatility due to its aerogel structure. Aerogels are ultra-light materials created by removing the liquid component from a gel while keeping its solid framework intact. The result is a material with an extremely low density, high surface area, and exceptional porosity.

In the case of graphene aerogels, graphene sheets are interconnected to form a 3D network that holds air within its pores, making the material incredibly light—often less than 0.2 g/cm³, which is lighter than air. This makes graphene aerogels among the lightest solids known to man. Despite their lightness, they can have significant mechanical strength and excellent thermal and electrical conductivity due to the inherent properties of graphene.

Properties of Graphene Aerogels

Graphene aerogels possess several remarkable properties that make them highly versatile and suitable for a wide range of industrial applications:

1. Ultra-Low Density

- Graphene aerogels are known for their extreme lightness. Their density can be as low as 0.16 g/cm³, which is significantly lower than traditional aerogels or most materials.

- This makes them ideal for lightweight applications, particularly in industries where weight reduction is critical.

2. High Surface Area

- The surface area of graphene aerogels can be extremely high—up to 1000 m²/g or more. This high surface area allows for greater interaction with gases, liquids, or other materials, making them ideal for adsorption and catalysis.

3. Mechanical Strength

- Despite their low density, graphene aerogels have remarkable mechanical properties. They can withstand significant stress while maintaining their structure, making them suitable for use in structural applications where weight and strength are both crucial.

4. High Thermal and Electrical Conductivity

- Graphene itself is an excellent conductor of heat and electricity, and these properties are retained in graphene aerogels. This makes them ideal for thermal management and energy storage applications, where good conductivity is important.

5. Super Absorbency

- Due to their porous structure, graphene aerogels have a high absorption capacity for both liquids and gases. This makes them highly effective in applications such as oil spill cleanup or filtering toxic substances from water or air.

6. Superelasticity

- Graphene aerogels can exhibit superelasticity, meaning they can compress to a fraction of their original size and return to their original shape without damage. This property makes them ideal for applications that require materials to undergo significant deformation without losing their integrity.

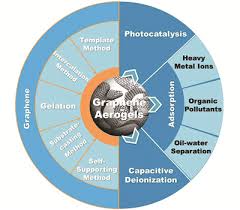

Production Methods of Graphene Aerogels

The production of graphene aerogels typically involves the following steps:

1. Synthesis of Graphene Oxide

- Graphene oxide (GO) is usually the precursor for graphene aerogels. It is produced by oxidizing graphite to introduce oxygen-containing functional groups such as epoxides, hydroxyls, and carboxyls. This makes the graphene oxide sheets dispersible in water and allows for the creation of a gel-like structure.

2. Gelation Process

- Once the graphene oxide is dispersed in water, a hydrogel is formed by adding a crosslinking agent. This results in a gel-like structure where the graphene oxide sheets are interconnected.

3. Reduction

- The graphene oxide gel is then reduced, often through chemical reduction or thermal treatment, to convert it into reduced graphene oxide (rGO). This process restores the conductivity of the material and enhances its properties.

4. Freeze Drying

- The final step in creating a graphene aerogel is freeze-drying, which removes the solvent from the gel and leaves behind the porous structure of the aerogel. The result is a highly porous, low-density material with the desired characteristics of graphene.

Applications of Graphene Aerogels

Graphene aerogels have a wide range of applications in diverse fields due to their unique properties. Some of the most exciting and promising applications include:

1. Energy Storage

- Supercapacitors: Graphene aerogels are being explored as electrode materials in supercapacitors due to their high surface area and electrical conductivity. They can store large amounts of energy and deliver rapid bursts of power, making them ideal for applications like electric vehicles and renewable energy storage.

- Batteries: The excellent conductivity and porosity of graphene aerogels make them suitable for use in lithium-ion batteries and other advanced battery systems. They help to enhance the performance, charging speed, and lifetime of batteries.

2. Environmental Cleanup

- Oil Spill Cleanup: Graphene aerogels can absorb up to 900 times their weight in oil, making them incredibly effective in oil spill cleanup and hazardous waste management.

- Water Purification: Due to their high surface area and adsorptive capacity, graphene aerogels can be used for water filtration and removing heavy metals or toxins from water. They can also filter gases in polluted air, improving environmental protection efforts.

3. Aerospace Engineering

- Lightweight Structural Components: The extreme lightness and high strength of graphene aerogels make them ideal for use in aerospace and spacecraft applications. They can be used as thermal insulators or in lightweight composites for the construction of aircraft and satellites.

- Thermal Insulation: Graphene aerogels are excellent thermal insulators. Their low thermal conductivity makes them ideal for applications requiring heat shielding, such as in space missions or high-performance vehicles.

4. Heat Management and Conductive Materials

- Thermal Conductive Materials: The high thermal conductivity of graphene aerogels makes them ideal for managing heat in electronic devices, computers, and batteries. They can be used as cooling materials or heat sinks to ensure the safe operation of sensitive components.

- Conductive Fabrics: Graphene aerogels can be incorporated into fabrics to create conductive textiles, which can be used in wearable electronics or smart clothing.

5. Sensors and Actuators

- Gas and Chemical Sensors: The adsorptive properties and high surface area of graphene aerogels make them highly effective as sensing materials for detecting gases, chemicals, or even biological agents. They can be used in environmental monitoring or healthcare applications for detecting pollutants and toxins.

- Flexible Actuators: Graphene aerogels are also being studied for use in flexible actuators that can respond to external stimuli such as heat, electricity, or moisture.

Challenges and Future Directions

While the properties and applications of graphene aerogels are extremely promising, there are still some challenges that need to be addressed:

- Scalability: The production of high-quality graphene aerogels in large quantities can be difficult and expensive. Scaling up production methods while maintaining the material’s performance is an ongoing challenge.

- Cost: The high cost of graphene and the complex manufacturing processes can limit the widespread adoption of graphene aerogels in certain industries. More efficient production methods and reductions in material costs are needed.

- Durability: Although graphene aerogels are strong and flexible, their long-term durability under various environmental conditions (such as moisture, extreme temperatures, or mechanical stress) remains a topic of research.

Conclusion

Graphene aerogels are a game-changing material with a broad range of applications across industries, including energy storage, environmental cleanup, aerospace, and electronic devices. Their unique combination of lightweight, high surface area, superabsorbency, and electrical and thermal conductivity positions them as one of the most promising advanced materials for the future.

With ongoing advancements in production methods and material optimization, graphene aerogels have the potential to revolutionize industries, improve energy efficiency, and enhance environmental sustainability. As these materials become more cost-effective and accessible, they will undoubtedly play a key role in addressing some of the most pressing challenges in energy, environmental management, and high-performance engineering.