Exploring the Power and Potential of Ultrasonic Homogenizers

Introduction to Ultrasonic Homogenizers

Ultrasonic homogenizers, also known as ultrasonic processors, are versatile tools used for the efficient mixing, emulsifying, dispersing, and breaking down of materials in various industries. Utilizing high-frequency sound waves (typically in the range of 20 kHz to 100 kHz), these devices produce ultrasonic waves that generate intense shear forces, leading to the breaking of large particles into smaller, more uniform sizes. The ability to control particle size distribution is essential in many fields, including nanotechnology, pharmaceuticals, food processing, and environmental applications.

Ultrasonic homogenizers have become integral to the preparation and processing of nanomaterials, where precise particle size control and dispersion are crucial for optimizing performance. This article will explore the power and potential of ultrasonic homogenizers in a variety of applications, with a particular focus on their role in nanomaterial synthesis and processing.

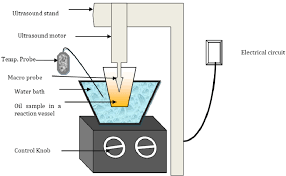

1. How Ultrasonic Homogenizers Work

Ultrasonic homogenizers operate through the principle of ultrasonic cavitation, a process in which high-frequency sound waves pass through liquids or slurries, causing the formation of microscopic bubbles. When these bubbles collapse, they generate intense heat, pressure, and shear forces, which can break down large particles, disperse aggregates, or promote chemical reactions. This process allows for highly efficient particle size reduction, emulsification, or dispersion, making ultrasonic homogenizers an indispensable tool in many applications.

- Cavitation Effects: The collapse of cavitation bubbles creates powerful shock waves that generate localized high temperatures and pressures. These forces break apart particles and promote homogenization at a molecular level, making the process suitable for applications in the creation of nanoparticles, emulsions, and suspensions.

- Temperature Control: Ultrasonic homogenizers also allow for temperature control, ensuring that sensitive materials are processed without degradation or loss of integrity due to heat.

2. Applications of Ultrasonic Homogenizers

A. Nanomaterial Synthesis and Dispersion

Ultrasonic homogenizers are widely used in the synthesis and dispersion of nanomaterials. Nanomaterials often exhibit unique properties due to their small size and large surface area, but achieving a uniform dispersion of nanoparticles is a challenging task. Ultrasonic homogenizers provide an efficient means of breaking down agglomerates and achieving uniformity in size, shape, and distribution.

- Carbon Nanotubes (CNTs): The dispersion of carbon nanotubes in various solvents is often challenging due to their tendency to aggregate. Ultrasonic homogenizers can be used to break these aggregates and ensure a stable dispersion, essential for their application in composites, electronics, and energy storage.

- Graphene and Graphene Oxide: Ultrasonic processing can be used to exfoliate graphite into graphene sheets and disperse graphene oxide in solvents, making it an essential process in producing high-performance materials for batteries, sensors, and conductive inks.

- Metal Nanoparticles: The synthesis of metal nanoparticles such as gold, silver, and platinum can benefit from ultrasonic homogenizers, which facilitate the creation of uniform and stable nanoparticle suspensions by preventing agglomeration during the synthesis process.

B. Pharmaceutical and Biomedical Applications

In the pharmaceutical industry, ultrasonic homogenizers play a key role in the preparation of drug formulations, including nanomedicines and nanoparticles for drug delivery systems. These systems require precise control over particle size to ensure proper absorption and distribution within the body.

- Nanoparticle Drug Delivery: Ultrasonic homogenizers are used to create stable dispersions of drug-loaded nanoparticles, enhancing bioavailability and providing controlled release profiles for drugs.

- Vaccine Formulation: The ability of ultrasonic homogenizers to create stable, uniform emulsions is critical in vaccine formulation, especially when dealing with liposomes and other nanoparticulate delivery systems.

- Emulsions for Topical Treatments: In cosmetics and skincare, ultrasonic homogenizers are used to prepare nanoemulsions for better skin penetration and longer-lasting effects of active ingredients.

C. Food Processing

In the food industry, ultrasonic homogenizers offer solutions for emulsifying, dispersing, and extracting bioactive compounds in food products. The ability to produce nanoscale emulsions and suspensions opens up new possibilities for improving food textures, flavors, and nutritional content.

- Food Emulsions: Ultrasonic homogenizers can be used to create fine emulsions of oils, water, and other ingredients, enhancing the texture and stability of products such as sauces, dressings, and beverages.

- Nutraceuticals: Nanoparticles produced using ultrasonic homogenizers can encapsulate bioactive compounds, such as vitamins and antioxidants, improving their bioavailability and absorption in the body.

- Homogenization of Dairy Products: Ultrasonic homogenization can enhance the stability of dairy products by breaking down fat globules, resulting in smoother textures and improved shelf life.

D. Environmental Applications

Ultrasonic homogenizers also have significant potential in environmental applications, particularly in water and wastewater treatment, and the removal of contaminants from industrial effluents. The powerful cavitation effects generated by ultrasonic waves can aid in the breakdown of pollutants, emulsification of oils, and even disinfection processes.

- Pollution Control: Ultrasonic homogenizers can aid in the degradation of pollutants such as heavy metals, organic contaminants, and petrochemical products in water bodies.

- Wastewater Treatment: In wastewater treatment, ultrasonic homogenizers are used for breaking down suspended particles, aiding in the removal of oils, greases, and other harmful substances from water.

- Oil Spill Cleanup: Ultrasonic cavitation can be used to break down oil slicks in water, facilitating the cleanup of oil spills and reducing the impact on marine life.

3. Advantages of Ultrasonic Homogenizers

A. High Efficiency and Speed

Ultrasonic homogenizers offer fast processing times compared to traditional mechanical mixing methods. This efficiency makes them ideal for high-throughput applications, where time is critical, such as in pharmaceuticals or nanomaterial synthesis.

B. Precise Control Over Particle Size

The ability to precisely control the particle size distribution is one of the major advantages of ultrasonic homogenizers. The intensity, duration, and frequency of the ultrasound waves can be adjusted to achieve the desired particle size, which is crucial in many applications like drug delivery systems, food emulsions, and nanomaterial synthesis.

C. Versatility

Ultrasonic homogenizers can be used for a wide range of materials, from liquids and suspensions to powders and pastes. Their versatility makes them valuable tools in various industries, including biotechnology, environmental science, and materials engineering.

D. Minimal Contamination

Unlike other methods of processing that may introduce contaminants (such as mechanical parts), ultrasonic homogenizers do not have moving parts in direct contact with the material, minimizing the risk of contamination during the process.

4. Challenges and Limitations

Despite their many benefits, ultrasonic homogenizers are not without challenges. Some of the main limitations include:

- Heat Generation: Prolonged ultrasonic processing can generate excessive heat, which may degrade sensitive materials. However, this issue can be mitigated through cooling systems or by controlling the processing time.

- Scalability: While ultrasonic homogenizers are highly effective on a small scale, scaling up the process for large-volume production can be challenging and may require specialized equipment.

- High Energy Consumption: Ultrasonic homogenization can consume significant amounts of energy, especially when processing large quantities, which may make it less cost-effective for certain applications.

5. Conclusion

Ultrasonic homogenizers are powerful tools with immense potential across a wide range of industries. From nanomaterial synthesis and pharmaceutical formulations to food processing and environmental applications, ultrasonic homogenizers provide efficient, versatile, and precise processing capabilities that significantly enhance product quality and performance. With ongoing advancements in ultrasonic technology, the power and potential of ultrasonic homogenizers are expected to grow, further cementing their role as indispensable tools in the modern industrial landscape.