Conversion Techniques of Cellulose into Biofuel: A Comprehensive Overview

Cellulosic biofuels, derived from the carbohydrate polymer cellulose, represent a promising renewable energy source. Unlike traditional biofuels, which are produced from food crops like corn and sugarcane, cellulosic biofuels are made from non-food plant materials such as agricultural residues, forest waste, and even algae. This offers a solution to the “food vs. fuel” debate, as it doesn’t compete with food production. The conversion of cellulose into biofuels involves several complex biochemical and thermochemical processes, each of which plays a critical role in maximizing the efficiency and sustainability of biofuel production.

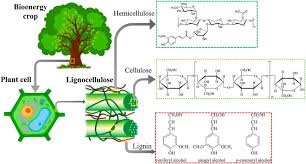

Understanding Cellulose and its Challenges

Cellulose is the most abundant biopolymer on Earth, composed of long chains of glucose molecules. Its structure is highly crystalline and resistant to degradation, which makes it difficult to break down and convert into usable biofuels. Therefore, the development of efficient conversion methods is a key challenge in the field of cellulosic biofuels.

Key Conversion Techniques

There are three primary conversion techniques used to transform cellulose into biofuels: enzymatic hydrolysis, thermochemical conversion, and fermentation. Each of these methods targets different components of biomass and utilizes different mechanisms to break down cellulose into fermentable sugars, which can then be processed into biofuels like ethanol, butanol, or even hydrogen.

1. Enzymatic Hydrolysis

Enzymatic hydrolysis is a biological process where enzymes are used to break down cellulose into its constituent sugars (primarily glucose). This process involves the following stages:

- Pretreatment: Cellulosic biomass is often treated to break down its complex structure and make it more accessible to enzymes. Common pretreatment methods include:

- Steam explosion

- Acid or alkaline treatment

- Ionic liquid-based pretreatment

- Organosolv treatment

- Enzyme Action: After pretreatment, cellulase enzymes, such as cellulase, β-glucosidase, and endoglucanase, are introduced. These enzymes hydrolyze the cellulose into fermentable sugars like glucose.

- Hydrolysis Efficiency: The efficiency of enzymatic hydrolysis is impacted by several factors, including the structure of the biomass, the type and concentration of enzymes, and the temperature and pH of the reaction.

- Challenges: The high cost of enzymes and the inefficiency of enzymatic conversion for certain biomass types are major obstacles in the commercialization of enzymatic hydrolysis for large-scale biofuel production.

2. Thermochemical Conversion

Thermochemical conversion involves the application of heat and chemicals to break down cellulose into biofuels. There are three primary thermochemical processes: pyrolysis, gasification, and hydrothermal liquefaction.

- Pyrolysis: This process involves the thermal decomposition of cellulose in the absence of oxygen. The high heat breaks down the cellulose into smaller molecules, producing bio-oil, syngas (synthetic gas), and biochar.

- Bio-oil produced through pyrolysis can be further refined into biofuels such as diesel, ethanol, and gasoline.

- Biochar can be used as a soil amendment, offering additional benefits to agricultural practices.

- Gasification: In gasification, cellulose is heated at high temperatures in a controlled, oxygen-limited environment, producing syngas—a mixture of hydrogen, carbon monoxide, and methane. This syngas can be further processed into fuels such as methanol or synthetic natural gas (SNG).

- Hydrothermal Liquefaction (HTL): This process uses water at high temperatures and pressures to break down cellulose into bio-oil. HTL is particularly effective for wet feedstocks like algae and food waste, as it does not require the drying of biomass before processing.

- Challenges: Thermochemical conversion methods often require high energy inputs, and the complexity of refining the by-products can increase production costs. Additionally, controlling the distribution of products (such as bio-oil versus syngas) remains a challenge.

3. Fermentation

Fermentation is a biochemical process by which microorganisms such as yeast or bacteria convert sugars into biofuels like ethanol or butanol. In the context of cellulosic biofuel production, fermentation typically follows the breakdown of cellulose into fermentable sugars.

- Direct Fermentation: This process involves the fermentation of sugars directly obtained from cellulose. However, due to the crystalline nature of cellulose, this approach is not straightforward and often requires enzymatic hydrolysis to release sugars first.

- Consolidated Bioprocessing (CBP): CBP is an emerging technology that integrates both the saccharification (conversion of cellulose to sugars) and fermentation steps into a single process. This is achieved by using genetically engineered microbes that can produce both cellulases (to break down cellulose) and fermenting enzymes in one step.

- Advantages: CBP could significantly reduce the costs and complexity of biofuel production, as it eliminates the need for separate enzyme applications and hydrolysis steps.

- Challenges: The development of robust, high-yielding microorganisms capable of efficiently performing both steps is still under research.

- Co-fermentation: In some cases, both hexoses (like glucose) and pentoses (like xylose) are produced from the breakdown of cellulose. Co-fermentation methods use microbes that can ferment both types of sugars simultaneously to enhance biofuel production.

4. Biochemical Upgrading

After the fermentation process, further upgrading is often needed to improve the yield and quality of the biofuel. This can include distillation, dehydration, and chemical upgrading processes to refine the raw biofuels into usable fuels like ethanol, butanol, or even advanced biofuels such as biodiesel.

Future Trends and Research Directions

As demand for renewable energy sources continues to grow, research into improving the efficiency and cost-effectiveness of cellulose-based biofuel production is ongoing. Some promising developments include:

- Advanced Enzymes and Microorganisms: Genetic engineering of microorganisms and enzymes could lead to more efficient conversion processes. Novel strains of bacteria or fungi capable of breaking down cellulose more effectively are a key area of exploration.

- Integrated Biorefineries: The integration of multiple biofuel production pathways within a single facility can optimize the overall yield and reduce costs. For example, integrating thermochemical and biochemical methods in a single process could improve the efficiency of biomass conversion.

- Second-Generation Feedstocks: Researchers are focusing on using a wider variety of non-food feedstocks, including algae, municipal waste, and dedicated energy crops like switchgrass, to enhance the sustainability of cellulosic biofuel production.

Conclusion

The conversion of cellulose into biofuel holds great promise for sustainable energy production. While significant technological advancements have been made, challenges remain, particularly in terms of cost-efficiency and scalability. However, with continued research and development, cellulosic biofuels may become a cornerstone of the global renewable energy landscape, providing a cleaner alternative to fossil fuels and helping to mitigate climate change.

By improving the various conversion techniques, including enzymatic hydrolysis, thermochemical methods, and fermentation processes, we can unlock the full potential of cellulose as a biofuel feedstock and pave the way toward a more sustainable energy future.