Cellulose Nanocrystals (CNC) in the Food Industry

Cellulose nanocrystals (CNC) are an emerging class of nanomaterials derived from natural cellulose fibers, and they have garnered significant interest due to their unique properties, such as high mechanical strength, biodegradability, and versatility. CNCs are being explored for a wide range of applications, with one of the most promising sectors being the food industry. Their use in food processing, packaging, and as food additives has the potential to revolutionize the industry by providing eco-friendly alternatives to conventional materials while improving the quality and functionality of food products.

This article delves into the role of cellulose nanocrystals in the food industry, discussing their properties, applications, and potential benefits.

1. Introduction to Cellulose Nanocrystals (CNC)

Cellulose is the most abundant natural polymer on Earth, found in the cell walls of plants. When cellulose is subjected to specific chemical or mechanical processes, it can be broken down into smaller, nanoscale particles, known as cellulose nanocrystals. These nanoparticles are crystalline structures with highly ordered molecular arrangements that confer remarkable properties, such as:

- High surface area: CNCs have a large surface-to-volume ratio, which makes them highly reactive and adaptable to a variety of applications.

- Mechanical strength: CNCs exhibit excellent mechanical properties, making them strong, lightweight materials.

- Biodegradability: As a natural material, CNCs are biodegradable and environmentally friendly.

- Non-toxicity: CNCs are non-toxic and safe for consumption, making them ideal for food-related applications.

These properties make CNCs a promising material in a variety of industries, especially in food science and technology.

2. Synthesis of Cellulose Nanocrystals

CNCs are typically extracted from natural sources such as wood, cotton, or other plant fibers through methods such as acid hydrolysis or mechanical processing. The most common method of CNC extraction is acid hydrolysis, where strong acids like sulfuric acid are used to break down the amorphous regions of cellulose, leaving behind the crystalline portions. This process results in the production of highly ordered nanocrystals with a rod-like or needle-like shape.

In addition to acid hydrolysis, other methods such as mechanical grinding, ultrasonication, and enzymatic treatments can also be used to produce CNCs. These techniques allow for the production of CNCs with varying sizes and surface charges, depending on the desired application.

3. Properties of Cellulose Nanocrystals

The distinctive properties of CNCs make them highly desirable for a wide range of food applications:

A. High Mechanical Strength

CNCs possess exceptional mechanical strength and stiffness due to their crystalline structure, which makes them suitable for reinforcing other materials, such as biodegradable films and coatings in the food industry.

B. Biodegradability and Sustainability

CNCs are derived from renewable plant sources, making them an eco-friendly alternative to synthetic materials. Their biodegradability ensures minimal environmental impact, which is crucial in industries that are striving for sustainability.

C. High Surface Area and Reactivity

The large surface area of CNCs allows them to interact with other substances, such as proteins, lipids, and polysaccharides, making them versatile in various food applications, including emulsions and stabilizing agents.

D. Non-Toxic and Safe for Consumption

CNCs are non-toxic and safe for use in food products, which is a critical requirement for any material used in the food industry. Their natural origin and the use of mild extraction methods make them ideal candidates for food-related applications.

4. Applications of Cellulose Nanocrystals in the Food Industry

Cellulose nanocrystals are finding numerous applications in the food industry, ranging from food packaging to functional food ingredients. Some of the key areas where CNCs are being utilized include:

A. Food Packaging

One of the most promising uses of CNCs in the food industry is in food packaging. Due to their high mechanical strength, CNCs can be incorporated into biodegradable films and coatings to enhance their performance. These nanocomposites offer several benefits over conventional packaging materials:

- Enhanced strength and durability: CNCs reinforce packaging materials, improving their tensile strength and flexibility.

- Barrier properties: CNC-based films can act as effective barriers to moisture, gases, and light, which helps prolong the shelf life of food products.

- Biodegradability: Unlike conventional plastic packaging, CNC-based films are biodegradable, reducing the environmental impact of food packaging waste.

The use of CNCs in food packaging aligns with the growing trend toward sustainable packaging solutions in the food industry.

B. Food Additives and Emulsifiers

CNCs have the ability to stabilize emulsions, making them useful as emulsifying agents in food products such as dressings, sauces, and beverages. Their high surface area and surface charge allow them to interact with both oil and water phases, improving the stability and texture of emulsions.

- Emulsification: CNCs can help create stable emulsions in food products, preventing phase separation and improving texture.

- Fat replacement: CNCs can also be used to reduce the fat content in food products while maintaining desired texture and mouthfeel.

C. Nutrient Delivery Systems

CNCs can be used as carriers for the controlled release of nutrients, vitamins, or bioactive compounds in functional foods. The structure and surface properties of CNCs allow them to encapsulate active ingredients and release them gradually, which can enhance the bioavailability and effectiveness of these compounds in the body.

- Encapsulation: CNCs can encapsulate sensitive ingredients like vitamins, minerals, and antioxidants, protecting them from degradation and ensuring their stability during storage and processing.

- Controlled release: The slow release of nutrients from CNC-based systems can provide sustained benefits for health and wellness.

D. Food Texture and Rheology Modifiers

In addition to emulsification, CNCs can be used to modify the texture and rheological properties of food products. They can be added to various food matrices to adjust their viscosity, improve mouthfeel, and enhance sensory properties. CNCs are especially useful in products like yogurts, ice creams, and gels.

- Viscosity control: CNCs can increase the viscosity of food products, enhancing their creaminess and texture.

- Improved mouthfeel: The inclusion of CNCs can improve the sensory attributes of foods, providing a smoother or more consistent texture.

E. Antioxidant and Antimicrobial Properties

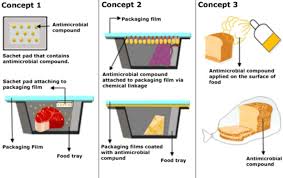

Cellulose nanocrystals have also been explored for their antioxidant and antimicrobial properties, which can help extend the shelf life of food products. By incorporating CNCs with natural antimicrobial agents, such as essential oils or polyphenols, food manufacturers can create food packaging materials that protect against microbial growth and oxidative damage.

- Antioxidant packaging: CNCs can be incorporated with antioxidants to help preserve the freshness and nutritional value of food.

- Antimicrobial coatings: CNC-based coatings can provide protection against microbial contamination in fresh produce, meats, and dairy products.

5. Challenges and Future Directions

While cellulose nanocrystals hold significant promise in the food industry, there are still several challenges to overcome:

- Scalability: The production of CNCs on a large scale for the food industry remains a challenge, as efficient and cost-effective methods for mass production need to be developed.

- Regulatory approval: The use of CNCs in food products and packaging must meet regulatory standards for safety and labeling, which may vary across regions.

- Consumer acceptance: As with any new technology, the acceptance of CNCs in food applications depends on consumer perceptions of safety, sustainability, and health benefits.

However, ongoing research and development in the field of nanotechnology are expected to address these challenges, leading to broader adoption of CNCs in the food industry.

6. Conclusion

Cellulose nanocrystals (CNCs) are emerging as versatile, eco-friendly materials with significant potential for improving food products and processes. From enhancing food packaging to stabilizing emulsions and delivering nutrients, CNCs offer innovative solutions that align with the growing demand for sustainability and functional foods. As research and production methods continue to advance, the role of CNCs in the food industry is expected to expand, contributing to more efficient, sustainable, and health-conscious food production.