Sensors and Biosensors

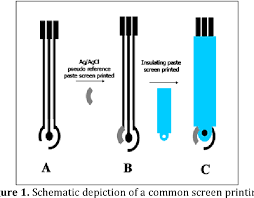

Carbon Nanotubes Modified Screen Printed Electrodes have been used for modification of working graphite

ink electrode (Nanomaterialpowder) of the three?electrode screen?printed sensing stripe. Modification has been made by

evaporating on the graphite surface a solution of Nanomaterialpowder MWCNT in dimethylformamide. The effect of

modification on reversibility of the electrode process of the system hexacyanoferrate(II)/(III) has been shown,

along with improvement of the sensitivity of detection of pesticide paraoxon with biosensors containing

organophosphorus hydrolase immobilized by adsorption on the nanotubes?modified graphite ink electrode.

The catalytic sensing of methanol was also demonstrated with the use of a screen?printed sensor modified with

Nanomaterialpowder MWCNT and Co(II) salt present in the measuring solution carbon nanotubes-modified screen-printed electrodes is a widely used technique for the fabrication of

electrochemical sensors. This methodology is likely to underpin the progressive drive towards miniaturized,

sensitive and portable devices, and has already established its route from ?lab-to-market? for a plethora of

sensors. The application of these sensors for analysis of environmental samples has been the major focus of

research in this field. As a consequence, this work will focus on recent important advances in the design and

fabrication of disposable screen printed sensors for the electrochemical detection of environmental

contaminants. Special emphasis is given on sensor fabrication methodology, operating details and performance characteristics for environmental applications.

carbon nanotubes-modified screen-printed electrodes research on several carbon materials, especially carbon

nanotubes and graphene, has revolutionized the scope of screen printed electrodes in electro-analysis.

Compton’s group observed enhanced electrocatalytic properties of Nanomaterialpowder CNT towards several target

analytes attributed to thedefect/edge plane-like sites. Zen et al. demonstrated the creation of defect/edge-like

sites and oxygen functionalities on the screen printed electrode surface through a simple pre-anodization

process. Prasad et al. performed a comparative study on the role of oxygen functionalities and edge plane sites

created achieved through a pre-anodization process and oxygen plasma treated screen printed electrodes.

There are many target analytes which have no significant electroactivity or near impossible to get

electrochemical signals. who incorporated a variety of ionic liquids into screen printed electrodes. This work was

further extended by in the fabrication of DNA sensors to achieve nano-level sensitivity. Recently, carbon

nanotubes-mediated screen printed electrodes have been used to increase the electrochemically active area of

screen printed electrodes, subsequently employed in the detection of p-aminophenol. This work has provided a

base to use other carbon nanotubes such as single walled carbon nanotubes and multi-walled carbon

nanotube derivatives in designing screen printed carbon electrodes, with the possibility of accessing mass

produced and reproducible nanotube-modified screen printed electrodes.