Carbon Nanofibers for Superior Conductivity in Supercapacitors: Advancing Energy Storage Technology

In the search for more efficient and sustainable energy storage solutions, supercapacitors have emerged as a promising alternative to traditional batteries. These energy storage devices are capable of delivering rapid bursts of power, making them ideal for applications such as electric vehicles, portable electronics, and renewable energy systems. One of the key challenges in enhancing the performance of supercapacitors lies in improving their conductivity, which directly impacts their efficiency and energy density.

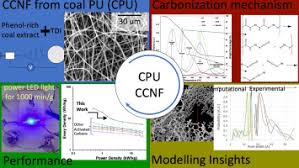

Enter carbon nanofibers (CNFs)—a material that has garnered significant attention for its exceptional electrical conductivity, mechanical strength, and flexibility. By incorporating carbon nanofibers into the design of supercapacitors, researchers are unlocking new possibilities for faster charging, higher energy storage capacity, and longer lifespans. This article explores the role of carbon nanofibers in enhancing the conductivity of supercapacitors and examines their potential for revolutionizing energy storage technologies.

What Are Carbon Nanofibers?

Carbon nanofibers are cylindrical structures composed of carbon atoms, typically arranged in a graphitic structure, and are often referred to as nanotubes or nanowires due to their nanometer-scale diameters. These nanofibers possess remarkable properties, including high surface area, excellent electrical conductivity, and outstanding mechanical strength, making them ideal candidates for use in energy storage devices such as supercapacitors.

Carbon nanofibers are typically synthesized using techniques such as chemical vapor deposition (CVD), electrospinning, or arc discharge. The resulting fibers can vary in size, length, and structure, which allows for customization depending on the intended application. These nanofibers are typically used as conductive additives in electrode materials, improving the overall performance of supercapacitors.

How Do Carbon Nanofibers Improve Conductivity in Supercapacitors?

Supercapacitors store energy electrostatically, unlike batteries, which rely on chemical reactions to store and release energy. In supercapacitors, energy is stored in the form of electric charge between two electrodes, with an electrolyte separating them. The performance of supercapacitors depends heavily on the materials used for the electrodes, particularly their conductivity and surface area.

Carbon nanofibers contribute to superior conductivity in supercapacitors in the following ways:

- Enhanced Electrical Conductivity: Carbon nanofibers have an excellent ability to conduct electricity due to their graphitic structure. By incorporating CNFs into the electrode material, the electrical conductivity of the supercapacitor is significantly improved, allowing for faster electron movement between the electrode and electrolyte. This results in enhanced power delivery and faster charging and discharging cycles.

- High Surface Area for Charge Storage: Carbon nanofibers have a large surface area, which increases the amount of charge that can be stored within the supercapacitor. The high surface area of CNFs allows for more electrostatic charge to accumulate at the electrode-electrolyte interface, improving the energy density of the supercapacitor.

- Improved Electrode-Material Conductivity: Carbon nanofibers can be used as a conductive matrix or coating for electrode materials, improving the overall conductivity of the electrode material. This conductive network allows for better electron transfer during charge and discharge cycles, leading to faster and more efficient energy storage.

- Flexible and Lightweight: The flexibility and lightweight nature of carbon nanofibers make them ideal for use in flexible and portable supercapacitors. These properties allow for the development of next-generation supercapacitors that can be integrated into various devices, from wearable electronics to flexible solar panels.

Advantages of Using Carbon Nanofibers in Supercapacitors

The incorporation of carbon nanofibers into supercapacitors offers several advantages that enhance the performance, efficiency, and versatility of these energy storage devices:

- Increased Power Density: The high conductivity of carbon nanofibers enables faster electron movement, which leads to improved power density. Supercapacitors with higher power density can deliver more rapid bursts of energy, making them suitable for applications that require quick energy release, such as in regenerative braking systems in electric vehicles.

- Enhanced Cycle Life: One of the key advantages of supercapacitors over traditional batteries is their ability to endure many charge and discharge cycles without significant degradation. Carbon nanofibers contribute to this enhanced cycle life by improving the mechanical properties and stability of the electrode material. This makes supercapacitors with CNFs more durable and longer-lasting.

- Faster Charging and Discharging: Carbon nanofibers enable rapid electron transport, which reduces the time required for charging and discharging. This faster response time makes supercapacitors with CNFs ideal for applications that demand quick energy delivery, such as in electric vehicles, power backup systems, and mobile devices.

- Lightweight and Flexible Designs: Carbon nanofibers are both lightweight and flexible, making them suitable for applications in portable and wearable electronics. Supercapacitors can be designed to be thin and flexible without sacrificing performance, opening up possibilities for integration into flexible electronics, wearable devices, and even clothing with embedded energy storage.

- Environmentally Friendly: Carbon nanofibers, particularly when derived from renewable sources such as biomass, can offer an environmentally friendly alternative to conventional electrode materials. The sustainability of carbon nanofiber-based supercapacitors is a key factor in the growing interest in these devices for green energy applications.

Applications of Carbon Nanofibers in Supercapacitors

Carbon nanofibers are being incorporated into a wide range of supercapacitor applications due to their ability to improve performance and efficiency. Some of the most promising applications include:

- Electric Vehicles (EVs): In electric vehicles, supercapacitors equipped with carbon nanofibers can deliver rapid bursts of power during acceleration and regenerative braking. These supercapacitors complement the traditional battery systems by providing quick power during short-duration events, extending the battery life and improving overall vehicle performance.

- Portable Electronics: Carbon nanofiber-based supercapacitors can be used to power portable electronics such as smartphones, laptops, and wearable devices. Their fast charge and discharge capabilities make them ideal for applications where quick bursts of energy are needed to power high-performance electronics.

- Renewable Energy Systems: In solar and wind energy systems, supercapacitors with carbon nanofibers can be used to store energy generated during peak production and release it during periods of low generation. This helps balance the intermittent nature of renewable energy sources and ensures a stable energy supply.

- Power Backup Systems: Carbon nanofiber-based supercapacitors are ideal for use in power backup systems, providing instant power when the main power source fails. Their ability to charge and discharge rapidly makes them effective for short-term energy storage during power outages or grid instability.

- Wearable Technology: The flexible nature of carbon nanofibers enables the creation of supercapacitors that can be integrated into clothing, accessories, or even human implants to power wearable technology. These energy storage devices can be used to power sensors, health monitoring devices, or fitness trackers.

Challenges and Future Directions

While carbon nanofibers offer tremendous potential for improving the performance of supercapacitors, several challenges need to be addressed:

- Manufacturing Cost: The production of high-quality carbon nanofibers can be expensive, particularly when compared to traditional materials used in supercapacitors. Reducing the cost of production is crucial for making carbon nanofiber-based supercapacitors commercially viable on a large scale.

- Material Stability: Although carbon nanofibers contribute to enhanced conductivity and cycle life, ensuring their long-term stability in supercapacitors remains a challenge. Researchers are working to improve the durability of CNFs in various environmental conditions to maximize their lifespan.

- Scaling Up Production: Scaling up the production of carbon nanofibers while maintaining their high quality is essential for large-scale applications. Efforts are underway to develop more efficient and cost-effective manufacturing processes for CNFs.

- Energy Density: While carbon nanofibers significantly improve the power density and efficiency of supercapacitors, further research is needed to enhance the energy density of CNF-based supercapacitors. Increasing the energy storage capacity will make them more competitive with traditional battery technologies.

Conclusion

Carbon nanofibers are a transformative material for improving the conductivity and performance of supercapacitors. With their exceptional electrical conductivity, high surface area, and mechanical strength, CNFs are helping to create more efficient, durable, and fast-charging energy storage devices. From electric vehicles and portable electronics to renewable energy systems and wearable technologies, the applications of carbon nanofiber-based supercapacitors are vast and varied.

As research continues to address challenges such as cost, scalability, and energy density, carbon nanofibers have the potential to revolutionize the energy storage industry, providing a sustainable and efficient solution for the growing global demand for clean energy. The future of energy storage is bright, and carbon nanofibers will play a key role in shaping that future.