Bulk Graphene Production from Waste Materials

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is a revolutionary material known for its extraordinary mechanical, electrical, and thermal properties. Despite its remarkable potential across industries, large-scale production of high-quality graphene remains a significant challenge, particularly due to high costs and environmental concerns associated with traditional manufacturing methods. Recent advances have focused on producing bulk graphene from waste materials, presenting a sustainable and cost-effective alternative.

Why Bulk Graphene Production is Important

- Industrial Demand:

- Graphene’s applications span electronics, energy storage, composites, water purification, and medical devices. Meeting industrial demand requires scalable production methods.

- Cost Constraints:

- High costs of graphene production limit its widespread adoption in commercial applications. Utilizing waste materials offers a cost-effective solution.

- Environmental Sustainability:

- Conventional methods often involve energy-intensive processes and harmful chemicals. Recycling waste materials reduces environmental impact and promotes sustainability.

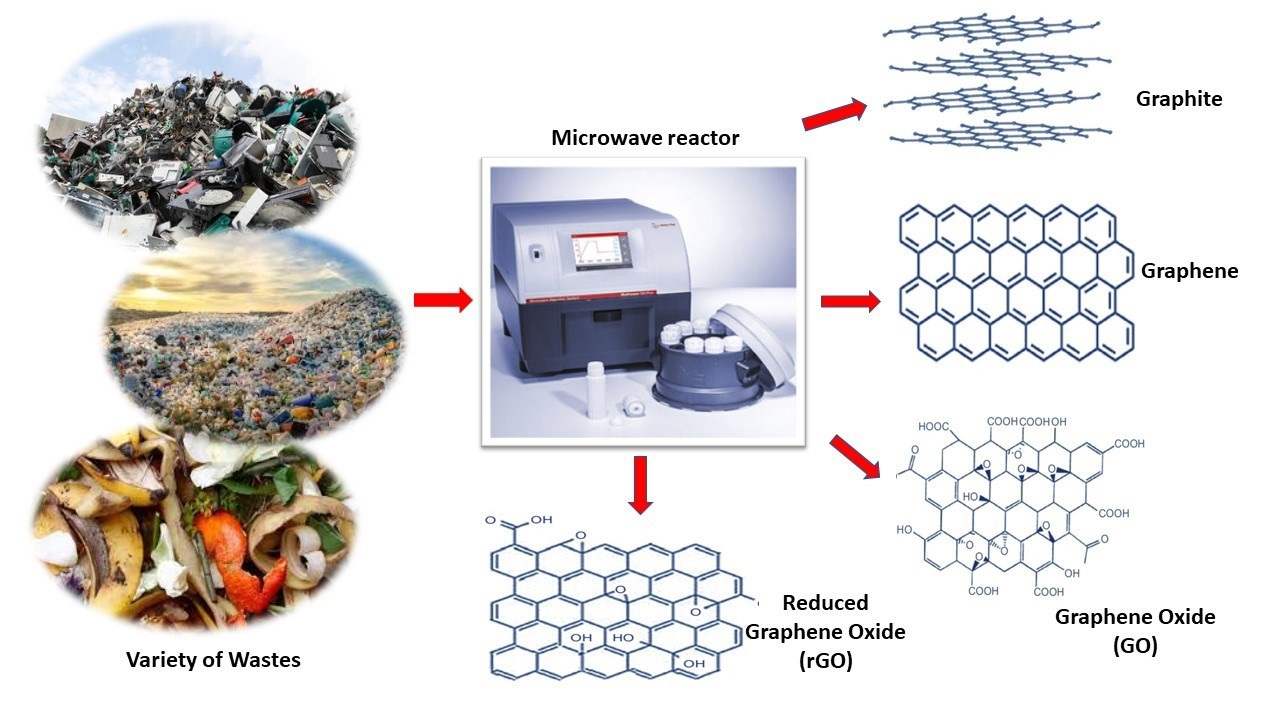

Sources of Waste Materials for Graphene Production

- Plastic Waste:

- Techniques like pyrolysis and chemical vapor deposition (CVD) can convert plastic waste into graphene, offering a dual benefit of waste management and material synthesis.

- Organic Waste:

- Agricultural residues, such as corn husks and banana peels, have been used to produce graphene via pyrolysis, leveraging their high carbon content.

- Coal and Petroleum By-products:

- Waste from the coal and petroleum industries, such as coke and tar, can be processed into graphene, providing value-added utilization of industrial by-products.

- Electronic Waste:

- Carbon-rich components from discarded electronics can serve as precursors for graphene synthesis.

Methods for Producing Graphene from Waste Materials

- Thermal Processes:

- Pyrolysis involves heating carbon-rich waste materials in an oxygen-free environment to produce graphene or graphene oxide.

- Chemical Exfoliation:

- Liquid-phase exfoliation uses solvents to separate graphene layers from waste-derived graphite.

- Electrochemical Methods:

- Electrolysis of carbon-containing waste can produce graphene with controlled layer thickness and quality.

- Plasma-Assisted Techniques:

- Plasma methods use high-energy plasmas to break down carbon-rich waste into graphene, offering high purity and scalability.

Potential Applications of Waste-Derived Graphene

- Energy Storage:

- Graphene-based batteries and supercapacitors benefit from the material’s high conductivity and surface area.

- Water Purification:

- Graphene membranes enable efficient filtration and desalination, offering sustainable solutions for clean water.

- Composites:

- Waste-derived graphene enhances the strength and flexibility of polymer composites for automotive and aerospace industries.

- Electronics:

- Flexible and lightweight graphene-based electronics can be fabricated using cost-effective methods.

- Sensors:

- Graphene’s sensitivity to various chemicals and biological agents makes it ideal for environmental and medical sensing applications.

Challenges in Bulk Graphene Production from Waste

- Material Quality:

- Achieving consistent quality and desired properties from waste-derived graphene remains a challenge.

- Scalability:

- Transitioning from laboratory-scale production to industrial-scale manufacturing requires further optimization.

- Contamination:

- Waste materials may introduce impurities, necessitating additional purification steps.

- Economic Viability:

- While waste materials are inexpensive, the cost of processing and purification must be competitive with traditional methods.

Future Directions and Opportunities

- Improved Techniques:

- Developing more efficient and scalable methods for waste-to-graphene conversion is critical.

- Policy and Collaboration:

- Government incentives and partnerships between academia and industry can accelerate advancements in this field.

- Integration with Circular Economy:

- Waste-derived graphene production aligns with the principles of a circular economy, promoting resource efficiency and sustainability.

- New Markets:

- As costs decrease and production scales up, waste-derived graphene can enable innovative applications in emerging industries like wearable technology and green energy.

Conclusion

Producing bulk graphene from waste materials offers a promising pathway to meet industrial demands sustainably and cost-effectively. By leveraging advancements in processing techniques and fostering collaborations, this approach has the potential to revolutionize graphene production while addressing global waste management challenges. The future of graphene lies not only in its exceptional properties but also in its ability to drive sustainable innovation across industries.