Battery Coating with Nanotechnology: Revolutionizing Energy Storage

The growing demand for efficient, safe, and long-lasting energy storage solutions has fueled innovations in battery technology. Among the various advancements, nanotechnology has emerged as a transformative tool, offering a way to enhance battery performance through the development of advanced coatings. These nanostructured coatings can improve a battery’s efficiency, lifespan, safety, and energy density, marking a significant leap in the capabilities of lithium-ion batteries, sodium-ion batteries, and other energy storage systems.

This article explores how battery coating with nanotechnology is changing the landscape of energy storage, with a focus on how nanocoatings enhance battery functionality and the future prospects of this innovative approach.

What is Battery Coating with Nanotechnology?

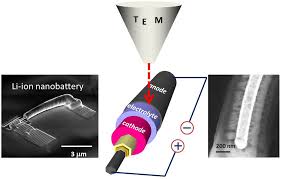

Battery coating with nanotechnology involves the application of nano-sized materials to the surface of battery components such as electrodes, separators, and current collectors. These nanocoatings can improve the electrochemical properties, structural integrity, and safety of the battery, all while maintaining or improving performance over extended charge/discharge cycles.

Nanotechnology-based coatings typically utilize nanomaterials like carbon nanotubes (CNTs), graphene, nanoparticles, and nanostructured polymers. These materials are chosen for their exceptional properties, such as high conductivity, thermal stability, mechanical strength, and flexibility.

How Nanotechnology Coatings Enhance Battery Performance

Nanotechnology coatings play a crucial role in improving several key attributes of batteries, including energy density, cycle life, safety, and charging speed.

1. Improved Energy Density

One of the primary goals in battery development is to increase energy density, or the amount of energy a battery can store relative to its size and weight. Nanotechnology coatings contribute to this by enhancing the electrode materials and improving ion conductivity.

- Graphene coatings: Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, is known for its exceptional electrical conductivity and large surface area. Coating electrodes with graphene can enhance the battery’s ability to store and transfer energy, leading to higher energy density.

- Carbon nanotubes (CNTs): CNTs have a high surface area and excellent conductivity, which improve the performance of anode and cathode materials. By applying CNT-based coatings to electrodes, the overall capacity and energy storage of the battery can be significantly increased.

2. Extended Cycle Life

As batteries undergo multiple charge and discharge cycles, they experience degradation due to the physical and chemical changes in the electrode materials. Nanotechnology coatings can help mitigate this issue by providing structural stability and improving ion mobility.

- Nanostructured coatings: The application of nanostructured materials to the electrodes can create a more stable surface that can withstand the expansion and contraction of the electrodes during charging and discharging. This leads to a reduction in wear and tear, improving the cycle life of the battery.

- Silicon-based nanocoatings: Silicon is a promising material for anode materials due to its high capacity, but it suffers from volumetric expansion during charge/discharge cycles. Nanocoatings of graphene or carbon nanotubes can help accommodate these expansions, reducing stress and preventing cracking of the anode material.

3. Enhanced Safety

Safety is a major concern with battery technologies, especially with the risk of thermal runaway, short-circuiting, or fire. Nanotechnology can improve battery safety by providing thermal stability and improved insulation.

- Thermal conductivity: Nanocoatings such as graphene and metal oxide nanoparticles provide superior thermal conductivity, helping to distribute heat more evenly throughout the battery. This can prevent overheating and mitigate the risk of thermal runaway.

- Fire-resistant coatings: Coatings made from nanomaterials like silica or phosphorus-based compounds can improve the fire resistance of batteries. These coatings act as barriers that delay the propagation of flames or prevent battery components from reaching temperatures high enough to ignite.

4. Faster Charging and Discharging

The rate at which a battery charges and discharges is directly related to how quickly ions can move between the anode and cathode. Nanocoatings can improve ion mobility, leading to faster charging and discharging cycles.

- Nanostructured electrodes: By coating electrodes with nanostructured materials such as carbon nanotubes, graphene, or nanoparticles, the surface area is maximized, enabling a greater number of ion channels and faster ion transport. This leads to significantly faster charging and discharging times.

- Supercapacitor integration: Nanocoatings can also facilitate the integration of supercapacitor-like properties in batteries, which help rapidly store and release energy. This is particularly useful in applications requiring quick bursts of energy, such as in electric vehicles (EVs) or portable electronics.

Types of Nanotechnology Coatings Used in Batteries

Different nanomaterials are used to create coatings that improve battery performance. The choice of nanomaterial depends on the type of battery and the specific performance goals.

1. Graphene Coatings

Graphene’s high electrical conductivity, large surface area, and mechanical strength make it an ideal candidate for enhancing battery coatings. Graphene-based coatings are used to increase the efficiency and performance of both the anode and cathode in lithium-ion batteries, improving capacity and charge/discharge rates.

- Graphene oxide can be used as a precursor for creating graphene-based coatings that are flexible, conductive, and lightweight.

- Reduced graphene oxide (rGO) is another form of graphene that is often applied in batteries to improve energy storage and cycle stability.

2. Carbon Nanotubes (CNTs)

Carbon nanotubes, with their high aspect ratio and excellent electrical properties, are used in battery coatings to improve conductivity and ion transport.

- Single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) are both used to coat electrode surfaces, providing superior conductivity and enhancing the overall battery performance.

- CNTs are often used in conjunction with other nanomaterials like graphene to create hybrid coatings that maximize both structural integrity and ion mobility.

3. Silicon-Based Nanocoatings

Silicon has a high theoretical capacity for lithium storage, making it a promising material for anode electrodes. However, its volumetric expansion during cycling can lead to cracking and capacity loss. Nanocoatings using carbon nanotubes or graphene are used to stabilize silicon and improve its cycling stability.

- Silicon nanowires: Coating silicon anodes with nanowires or nanoparticles allows for better stress accommodation, reducing cracking and improving overall cycle life.

4. Metal Oxide Nanoparticles

Metal oxide nanoparticles, such as titania (TiO2) and zinc oxide (ZnO), are incorporated into battery coatings to improve thermal stability, electrical conductivity, and safety.

- Titanium dioxide (TiO2) is used in battery coatings to improve thermal stability and safety by preventing overheating and thermal runaway.

- Zinc oxide (ZnO) nanoparticles can be used to enhance safety by acting as a fire retardant, preventing the spread of flames during battery failures.

Applications of Nanotechnology in Battery Coatings

Nanotechnology-enhanced battery coatings are finding applications in several industries, including:

1. Electric Vehicles (EVs)

Electric vehicles require high-performance batteries with long cycle life, fast charging, and high energy density. Nanotechnology-based coatings improve the safety, performance, and reliability of EV batteries, making them more suitable for mass adoption.

2. Consumer Electronics

Smartphones, laptops, and wearable devices require batteries that charge quickly and last longer. Nanotechnology coatings are used to enhance the efficiency, safety, and charging speed of batteries in these devices, improving the overall user experience.

3. Renewable Energy Storage

In the renewable energy sector, energy storage systems like solar or wind battery storage require long-lasting, efficient batteries. Nanotechnology coatings improve the performance and safety of these energy storage systems, enabling better management of renewable energy.

4. Military and Aerospace Applications

Batteries used in military and aerospace applications require high energy density, reliability, and safety. Nanotechnology-enhanced coatings help improve battery performance, reduce overheating risks, and extend battery life in these critical applications.

Future Outlook

The integration of nanotechnology in battery coatings is still in the early stages, but the potential for these coatings to revolutionize energy storage is vast. As researchers continue to develop new nanomaterials and coating techniques, we can expect further advancements in battery efficiency, safety, and sustainability.

Nanotechnology could also contribute to the development of solid-state batteries, which promise to offer higher energy densities and greater safety than conventional liquid electrolyte batteries. Nanocoatings will play a critical role in making these next-generation batteries a reality.

Conclusion

Battery coating with nanotechnology represents a major breakthrough in energy storage, offering significant improvements in capacity, cycle life, safety, and charging speed. By incorporating graphene, carbon nanotubes, and other nanomaterials, batteries are becoming more efficient, safer, and longer-lasting, opening the door to sustainable energy solutions across various industries.

As the technology evolves, nanotechnology-based coatings will play a crucial role in the development of next-generation batteries that power everything from electric vehicles to portable electronics, paving the way for a future with more efficient and reliable energy storage solutions.