Applications of Shape Memory Polymers and Their Composites

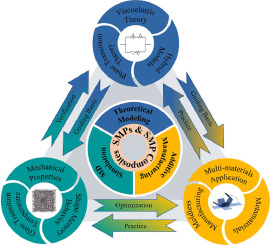

Shape Memory Polymers (SMPs) are a class of materials that have the ability to return to a predetermined shape when triggered by an external stimulus such as temperature, pH, light, or an electric field. These materials exhibit unique mechanical and thermal properties that make them suitable for a wide range of applications across various industries, from aerospace to medical devices. The incorporation of composites with shape memory polymers further enhances their functionality, leading to the creation of advanced materials with improved mechanical strength, durability, and responsiveness.

In this article, we will explore the diverse applications of Shape Memory Polymers (SMPs) and their composites, their key benefits, and the challenges associated with their implementation in different industries.

1. Introduction to Shape Memory Polymers (SMPs)

Shape Memory Polymers (SMPs) belong to a unique group of polymers that can “remember” a specific shape and revert back to it when exposed to a specific external stimulus. SMPs exhibit two key phases:

- Temporary Shape (Set Shape): The shape the polymer adopts when it is cooled or processed.

- Permanent Shape: The original, pre-programmed shape that the polymer returns to when triggered.

The ability of these materials to undergo reversible shape changes makes them highly attractive for a variety of functional applications. SMPs can be triggered by heat (thermal), light (photo), or other environmental stimuli, depending on the type of polymer and its specific application.

2. Applications of Shape Memory Polymers (SMPs)

a. Medical Devices and Implants

SMPs have gained significant attention in the medical field due to their ability to change shape in response to external stimuli. Some key applications include:

- Self-Expanding Stents: SMPs are used to create stents that can expand once inserted into the body. These stents are compressed for insertion and, upon exposure to body temperature, expand to their permanent shape, providing support to blood vessels or airways.

- Drug Delivery Systems: SMPs are used in controlled drug release systems, where the polymeric structure can change in response to stimuli (such as temperature), releasing drugs in a controlled manner.

- Orthopedic Devices: SMP-based materials are also used in orthopedic applications like braces or casts. These materials can adapt to the body’s shape after being heated or cooled, providing improved comfort and support.

b. Aerospace and Defense

In aerospace engineering, the lightweight, adaptable nature of SMPs makes them ideal for applications where materials need to change shape in response to temperature fluctuations or other conditions. Some key applications include:

- Deployable Structures: SMPs are used in deployable structures such as solar panels, antennas, and satellite components that must fold up for launch and then “deploy” when they reach space.

- Aerospace Actuators: SMPs are utilized in the development of actuators for aerospace systems. These actuators can change shape or stiffness when triggered, which can be advantageous for adjusting the aerodynamic characteristics of aircraft or spacecraft.

c. Smart Textiles and Clothing

Shape memory polymers have also found a place in the textile industry, particularly in the development of smart textiles. SMPs are integrated into fibers or fabrics to create clothes that adapt to external stimuli:

- Temperature-Responsive Clothing: Clothing that can change its shape or size in response to temperature fluctuations. For example, a jacket that expands in the cold to provide insulation and shrinks back when warmed.

- Self-Healing Fabrics: Some fabrics are embedded with SMPs that allow them to “heal” when damaged by returning to their original form after exposure to heat or light.

d. Automotive Industry

The automotive sector is increasingly looking at Shape Memory Polymers to develop innovative solutions for improving vehicle performance and comfort:

- Self-Healing Materials: SMPs are used to develop self-healing materials for automobile parts that can repair minor damage (like scratches or dents) when exposed to heat.

- Adaptive Seats and Interiors: SMPs are used in automotive seats and interiors, where the shape of the seat or components can be adjusted for better comfort or ergonomics when triggered by temperature.

e. Robotics and Actuators

In robotics, Shape Memory Polymers are used to create soft actuators that can change their shape or stiffness in response to external stimuli. This allows for more flexible and adaptable robots that can perform tasks in environments where traditional rigid robots would be ineffective.

- Soft Robots: SMP-based actuators are used in soft robots that can deform in complex ways. These robots are suitable for delicate tasks such as surgery, exploration, or agriculture.

- Artificial Muscles: SMPs are being developed for use in artificial muscles that mimic the movement and flexibility of biological muscles. These can be used in various robotic systems, from exoskeletons to medical devices.

3. Composites of Shape Memory Polymers

While Shape Memory Polymers are versatile on their own, they can be enhanced by incorporating them into composite materials. Composites of SMPs combine the advantages of SMPs with the mechanical strength, durability, and enhanced properties provided by fillers such as carbon fibers, fiberglass, nano-fillers, or inorganic particles.

a. Improved Mechanical Properties

The addition of fillers or reinforcements can significantly enhance the mechanical properties of SMPs, such as:

- Increased Strength: Adding carbon fiber or glass fibers to SMPs can increase the overall strength and stiffness, making the composite more suitable for load-bearing applications such as in aerospace and automotive industries.

- Enhanced Durability: Composites can improve the long-term stability and durability of SMPs, making them more reliable for demanding applications in harsh environments.

b. Multistimuli-Responsive Composites

The incorporation of fillers or functional nanoparticles can lead to multistimuli-responsive composites. For example, SMP composites that respond to a combination of temperature, light, and pH can have expanded functionality for applications in drug delivery, biomedical devices, and smart materials.

c. Shape Memory Polymeric Nanocomposites

The development of nanocomposites by incorporating nanoscale materials like carbon nanotubes (CNTs) or graphene into SMPs has opened new possibilities. These nanocomposites exhibit enhanced mechanical properties, electrical conductivity, and thermal stability.

- Enhanced Shape Memory Effect: Nanocomposites can have a more pronounced shape memory effect, with faster response times to external stimuli.

- Electrical Conductivity: The incorporation of conductive nanomaterials can allow the SMP composites to respond to electrical stimuli, expanding their use in actuators, sensors, and robotic applications.

4. Challenges and Limitations

Despite the promising applications and advantages, there are several challenges associated with the use of SMPs and their composites:

- Thermal Sensitivity: Most SMPs are primarily responsive to thermal stimuli, which may limit their use in applications requiring a broader range of responsive stimuli or more precise temperature control.

- Processing Complexity: The processing and shaping of SMPs, especially when used in composite form, can be challenging and require specialized equipment and techniques.

- Cost: High-performance SMPs, particularly those enhanced with nanomaterials, can be expensive to produce, limiting their widespread adoption in commercial applications.

- Environmental and Long-Term Stability: While SMPs are generally durable, exposure to extreme environmental conditions, such as high humidity or UV radiation, can degrade their properties over time.

5. Future Directions and Innovations

The potential of SMPs and their composites is vast, and ongoing research continues to expand their applications. Future directions include:

- Multifunctional Materials: Research is focused on creating multifunctional SMP composites that combine shape memory properties with other functionalities like conductivity, sensing, and self-healing.

- Bio-Inspired Designs: Inspired by natural organisms, scientists are developing bio-inspired SMPs that can mimic biological responses and adaptive behaviors, especially in medical and robotics applications.

- Environmentally Friendly SMPs: There is growing interest in developing biodegradable and eco-friendly SMPs, which can be used in medical applications or reduce environmental impact in industrial sectors.

6. Conclusion

Shape Memory Polymers and their composites represent a highly versatile class of materials with applications spanning multiple industries. From medical devices to aerospace, robotics, and automotive sectors, SMPs have the potential to revolutionize design and functionality. By enhancing these materials with composite reinforcements, such as carbon fibers, nanotubes, and other nanomaterials, researchers are unlocking new capabilities that were previously unimaginable.

While there are challenges to overcome, particularly in terms of cost, processing, and environmental stability, ongoing research and innovation will likely address these issues and expand the use of SMPs in advanced applications. As such, Shape Memory Polymers and their composites will continue to be a driving force in the development of smart materials with cutting-edge functionalities in the years to come.