Applications of Multi-Walled Carbon Nanotubes (MWCNTs)

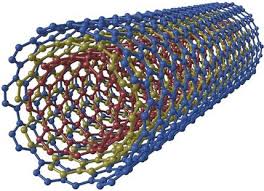

Multi-walled carbon nanotubes (MWCNTs), a subclass of carbon nanotubes (CNTs), have garnered significant attention due to their unique structure, exceptional mechanical properties, and versatile functionalities. These nanomaterials consist of multiple layers of carbon atoms arranged in a cylindrical shape, making them particularly strong, lightweight, and electrically conductive. MWCNTs are often compared to single-walled carbon nanotubes (SWCNTs), but their multi-layered structure offers enhanced properties in several areas, including thermal conductivity, strength, and chemical stability.

In this article, we explore the diverse applications of multi-walled carbon nanotubes (MWCNTs) in various industries, from electronics to medicine, energy, and environmental remediation.

1. Electronics and Electrical Devices

Electrical Conductivity in Nanoelectronics

MWCNTs exhibit high electrical conductivity, which makes them highly suitable for use in nanoelectronics. Their conductive properties are utilized in the following applications:

- Conductive films: MWCNTs are integrated into thin films used for electronic displays and conductive coatings. These films are employed in transparent conductive layers for touchscreens, displays, and solar cells.

- Electrode materials: MWCNTs are used as electrodes in batteries and supercapacitors, where their high conductivity enhances charge storage and energy discharge rates.

- Interconnects in integrated circuits: MWCNTs serve as interconnects in semiconductor devices, replacing traditional metals like copper, which are more prone to signal degradation and overheating.

Flexible Electronics

The inherent flexibility and mechanical strength of MWCNTs make them ideal for flexible electronics. They are incorporated into flexible circuits, smart textiles, and wearable devices, providing enhanced electrical conductivity while maintaining flexibility and durability.

2. Energy Storage and Conversion

Batteries

MWCNTs are used in the development of advanced batteries, particularly lithium-ion and sodium-ion batteries. Their high surface area and electrical conductivity contribute to improved charge/discharge efficiency, cycle life, and overall performance. Key applications include:

- Anode materials: MWCNTs are used as an additive in the anode materials of lithium-ion batteries, improving their energy density, charge rate, and thermal stability.

- Supercapacitors: MWCNTs are also employed in supercapacitors, which store energy in the form of electrostatic charge, offering rapid charge/discharge cycles and high power output. MWCNTs enhance the performance of supercapacitors by improving their capacitance and energy density.

Hydrogen Storage

MWCNTs have shown potential in hydrogen storage applications, which is crucial for fuel cell technology. The high surface area of MWCNTs allows them to absorb significant quantities of hydrogen molecules, making them viable candidates for hydrogen storage systems in fuel cell vehicles and energy generation.

Thermal Conductivity in Heat Sinks

Due to their high thermal conductivity, MWCNTs are integrated into heat sinks used in electronic devices, including computers, LEDs, and power electronics. These heat sinks help manage heat dissipation, preventing devices from overheating and improving their performance and longevity.

3. Composite Materials

Reinforcement in Polymers and Composites

MWCNTs are widely used as reinforcements in polymers, ceramics, and metals to create nanocomposites. These composites exhibit enhanced mechanical, thermal, and electrical properties, making them highly desirable in industries requiring high-performance materials.

- Polymer nanocomposites: MWCNTs are incorporated into polymers to improve their strength, ductility, and electrical conductivity. These composites are used in automotive, aerospace, and electronics industries.

- Structural composites: In aerospace, automotive, and sports equipment, MWCNTs are used to reinforce carbon fiber composites, enhancing their strength-to-weight ratio while maintaining flexibility.

Conductive Paints and Coatings

MWCNTs are added to paints and coatings to create conductive coatings. These are used for anti-static surfaces and as shielding materials for electromagnetic interference (EMI). The high conductivity of MWCNTs makes them ideal for such applications.

4. Medical and Healthcare Applications

Drug Delivery Systems

One of the most exciting applications of MWCNTs is in nanomedicine, particularly in drug delivery systems. The large surface area of MWCNTs allows them to efficiently carry a variety of drugs, including chemotherapeutic agents, antibiotics, and gene therapies.

- Targeted drug delivery: MWCNTs can be functionalized with specific molecules that target diseased cells or tissues. This allows for precise delivery of drugs, reducing side effects and improving treatment efficacy.

- Cancer treatment: MWCNTs can be used to deliver drugs directly to cancer cells, increasing the drug’s concentration at the site of action while minimizing damage to healthy cells.

Biosensors

MWCNTs are employed in biosensors for the detection of biomarkers associated with diseases. These sensors work by functionalizing MWCNTs with specific receptors that bind to biomolecules, triggering a detectable response. They are used for:

- Disease diagnostics: MWCNT-based biosensors enable rapid and sensitive detection of pathogens, viral infections, and cancer markers.

- Point-of-care diagnostics: Due to their small size and high sensitivity, MWCNT-based biosensors are ideal for portable point-of-care diagnostics in remote and resource-limited settings.

5. Environmental Applications

Water Purification

MWCNTs are increasingly used in water filtration and purification systems due to their ability to adsorb a wide range of contaminants, including heavy metals, organic pollutants, and bacteria.

- Heavy metal removal: MWCNTs can be functionalized to selectively bind to heavy metals, such as lead, cadmium, and arsenic, effectively removing these harmful substances from drinking water.

- Oil-water separation: MWCNTs are used in oil-water separation membranes, where they help efficiently remove oils and hydrophobic substances from water, making them valuable in oil spill cleanup efforts.

Environmental Sensors

MWCNTs are also employed in environmental monitoring systems, where they are integrated into sensors that detect pollutants and toxic gases. The high surface area and sensitivity of MWCNTs make them ideal for detecting low levels of environmental contaminants, such as carbon dioxide (CO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs).

6. Automotive and Aerospace Industries

Lightweight, High-Strength Materials

In both the automotive and aerospace industries, MWCNTs are used to develop lightweight composites with superior mechanical strength. These materials are essential for improving fuel efficiency, performance, and safety in aircraft and vehicles.

- Carbon-fiber composites reinforced with MWCNTs offer a high strength-to-weight ratio, making them ideal for use in aircraft parts, automotive bodies, and sporting equipment.

- Energy-efficient vehicles: In electric vehicles, the use of MWCNT-based composites contributes to reducing vehicle weight, thereby increasing battery life and overall energy efficiency.

Electromagnetic Shielding

MWCNTs are used in electromagnetic shielding materials, which are vital for protecting sensitive equipment from electromagnetic interference (EMI). In the automotive and aerospace sectors, these materials are applied to wiring, electronic components, and vehicle bodies.

Challenges and Future Directions

While MWCNTs offer numerous advantages, their large-scale production and integration into real-world applications present some challenges:

- Cost: The cost of producing high-quality MWCNTs remains relatively high, although advancements in production techniques may help reduce costs over time.

- Toxicity and Safety: The potential toxicity of MWCNTs, especially when inhaled or ingested, remains a subject of ongoing research. Safety protocols are essential when handling MWCNTs in industrial and medical applications.

- Scalability: The large-scale synthesis of MWCNTs with consistent quality remains a challenge. Advances in chemical vapor deposition (CVD) and other production techniques may help address this issue.

Conclusion

Multi-walled carbon nanotubes (MWCNTs) are at the forefront of a wide range of cutting-edge applications across industries, from electronics and energy storage to medicine, environmental remediation, and automotive engineering. Their combination of mechanical strength, electrical conductivity, and versatility makes them one of the most exciting materials in nanotechnology today. As research progresses and production techniques improve, MWCNTs are likely to play an even more significant role in shaping the future of technology and industry.