Advantages of Silicon Anode Materials for Lithium-Ion Batteries

Silicon-based anode materials are rapidly emerging as a promising alternative to traditional graphite anodes in lithium-ion batteries (LIBs). With the increasing demand for higher energy densities and faster charging times, the limitations of conventional graphite anodes have prompted researchers and manufacturers to explore new materials that can push the boundaries of battery performance. Among these, silicon has gained significant attention due to its remarkable properties and potential to revolutionize energy storage systems. This article delves into the advantages of silicon anode materials for lithium-ion batteries, exploring how they improve battery performance, lifespan, and sustainability.

1. Higher Energy Density

One of the most compelling advantages of using silicon anodes is the significantly higher energy density compared to conventional graphite anodes.

- Silicon’s Theoretical Capacity: Silicon can store much more lithium ions per unit mass than graphite. While graphite has a theoretical capacity of about 372 mAh/g, silicon can theoretically deliver up to 4200 mAh/g, a substantial increase. This means that silicon anodes can potentially increase the overall energy density of lithium-ion batteries by 10 times, leading to batteries with a higher capacity and longer runtime.

- Compact Power Storage: Due to its high energy density, silicon anodes allow for smaller, lighter batteries with the same or even greater energy storage capacity. This can significantly benefit portable electronics, electric vehicles (EVs), and renewable energy storage systems where battery size and weight are critical factors.

2. Improved Cycle Life and Durability

Silicon anodes, when engineered correctly, can offer better cycle life and durability compared to traditional graphite anodes.

- Silicon’s Potential for Long-Term Use: Silicon has a higher specific capacity, which allows for better retention of charge over extended cycles. Unlike graphite, which experiences degradation after several charge and discharge cycles, silicon can maintain its capacity for a longer period, leading to batteries that last longer and require fewer replacements.

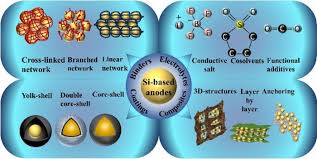

- Modification Techniques: Although pure silicon undergoes significant volume expansion and contraction during charge-discharge cycles, leading to material degradation, researchers have developed various approaches to mitigate this issue. By incorporating silicon into composites with materials like carbon, graphene, or other nanoparticles, the structural integrity of silicon anodes can be preserved, improving the overall cycle life.

3. Faster Charging Times

The ability to charge batteries quickly is a highly sought-after feature in consumer electronics and electric vehicles. Silicon anodes have been shown to enhance the charging speed of lithium-ion batteries, offering another significant advantage over graphite-based anodes.

- Faster Lithium-Ion Diffusion: The nanostructuring of silicon-based materials, such as silicon nanowires, can improve the diffusion of lithium ions within the anode, leading to faster charging times. This is particularly beneficial in applications like electric vehicles (EVs), where users demand quick recharge times.

- High Power Density: Silicon anodes can also improve the power density of lithium-ion batteries, allowing for faster energy discharge, which is vital in high-power applications, such as acceleration in electric cars.

4. Cost-Effectiveness and Sustainability

Despite the relatively high cost of silicon anode materials compared to graphite, the long-term sustainability and cost-effectiveness of silicon-based batteries are key considerations for the future of energy storage.

- Abundant Raw Material: Silicon is the second most abundant element in the Earth’s crust, which makes it a much more abundant and potentially less expensive raw material compared to the materials required for other advanced battery technologies. This abundance reduces the risks associated with material scarcity and price volatility, making silicon an ideal candidate for mass-scale adoption.

- Recycling Potential: Silicon is also more easily recycled compared to some other battery materials, offering long-term environmental and cost benefits. This is especially important as the world continues to push for more sustainable energy solutions and closed-loop recycling systems.

5. Compatibility with Existing Battery Manufacturing Processes

Another significant advantage of silicon anode materials is that they can be integrated into current lithium-ion battery manufacturing processes with relatively minimal changes.

- Scalable Manufacturing: The integration of silicon into existing battery technology is feasible with some modifications, allowing for scalable production and widespread adoption in consumer electronics and electric vehicles. Since silicon anodes can be incorporated into existing battery architectures, the transition from graphite to silicon anodes can be more seamless than the shift to entirely new technologies.

- Combinable with Graphite: Researchers are increasingly using a combination of silicon and graphite in the anode material. This hybrid approach allows for a balance between the high energy density of silicon and the stability of graphite, making it a more practical solution for commercial applications while still providing the advantages of both materials.

6. Environmental Impact

The environmental benefits of silicon as an anode material in lithium-ion batteries cannot be understated.

- Eco-Friendly Material: Silicon, unlike other rare materials used in batteries, such as cobalt, is abundant and non-toxic. This makes it a greener option for energy storage solutions, aligning with the increasing global demand for environmentally friendly technologies.

- Reduced Dependence on Rare Earth Metals: Many lithium-ion batteries today rely on rare and often environmentally problematic materials, such as cobalt and nickel. Silicon’s abundant availability and non-toxic nature reduce the dependence on these materials, contributing to a more sustainable battery production process.

7. Advanced Research and Innovation Potential

Silicon anode technology is still in the early stages of commercialization, and ongoing research continues to unlock new methods for improving its performance.

- Nanostructuring Techniques: Nanotechnology is playing a crucial role in enhancing the properties of silicon-based anodes. Techniques such as silicon nanowires, silicon nanostructures, and silicon-carbon composites are improving the efficiency and stability of silicon anodes, allowing for faster charging, higher capacity, and longer battery life.

- Hybrid Anodes: Combining silicon with other materials like graphene or conductive polymers can help alleviate some of the drawbacks of pure silicon, such as its tendency to expand and contract during cycling. These innovations offer exciting opportunities for further improving the performance of lithium-ion batteries.

Conclusion

Silicon-based anode materials present a highly promising solution to the challenges faced by traditional graphite anodes in lithium-ion batteries. With their higher energy density, faster charging capabilities, longer cycle life, and sustainability advantages, silicon anodes are set to play a crucial role in the future of energy storage. As research continues to refine and optimize silicon-based technologies, we can expect these batteries to drive significant advances in consumer electronics, electric vehicles, and renewable energy storage, paving the way for a more energy-efficient and sustainable future.