Abundance and Production of Praseodymium: A Critical Rare Earth Element

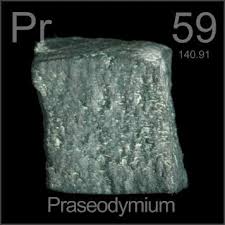

Praseodymium (Pr) is one of the rare earth elements (REEs) that play a crucial role in modern technologies, from electronics to renewable energy systems. As a soft, silvery metal, praseodymium is used in a variety of industrial applications, including the production of magnets, batteries, light sources, and aerospace components. This article delves into the abundance of praseodymium in nature, its production methods, and its global supply chain, providing insights into the challenges and opportunities in the praseodymium industry.

What is Praseodymium?

Praseodymium is a lanthanide element, often grouped with other rare earth metals in the periodic table. It has the chemical symbol Pr and atomic number 59. Praseodymium is highly valued for its magnetic and electrical properties, which make it an essential material in several high-tech industries, including electronics, energy storage, and defense technologies.

In its natural state, praseodymium is never found as a pure element but is usually extracted from minerals containing a mix of rare earth elements, such as monazite and bastnäsite.

Abundance of Praseodymium in the Earth’s Crust

Praseodymium is considered a rare earth element because it is not found in abundance like more common metals such as iron or copper. However, its concentration in the Earth’s crust is not as low as some other rare earth elements.

- The average abundance of praseodymium in the Earth’s crust is estimated to be ~ 9.2 parts per million (ppm).

- While this makes it relatively abundant compared to some other heavy rare earth elements, praseodymium is still considered rare when compared to the abundance of more commonly used metals like iron (which has a crustal abundance of around 5,000 ppm).

The natural abundance of praseodymium places it among the light rare earth elements (LREEs), which are generally more abundant and easier to extract than the heavy rare earth elements (HREEs). Despite being classified as a “rare” earth metal, praseodymium is still much more abundant than the precious metals like gold or platinum.

Sources of Praseodymium

Praseodymium is primarily obtained as a byproduct of the extraction of other rare earth elements, rather than being mined directly as a standalone element. The most important sources of praseodymium are:

1. Monazite Ore

Monazite is a phosphate mineral that contains a significant amount of rare earth elements, including praseodymium. It is one of the primary sources of light rare earth elements and is found in sand deposits, particularly in regions like India, Brazil, and Australia.

2. Bastnäsite Ore

Bastnäsite is another important source of rare earth elements and contains significant amounts of lanthanum, cerium, and praseodymium. This ore is commonly mined in places such as China and the United States, particularly in California.

3. Ion-adsorption Clays

Ion-adsorption clays, particularly found in Southern China, are rich in rare earth elements. These ores are particularly valuable for their ability to adsorb rare earth ions from water, allowing for cost-effective extraction of praseodymium and other elements in the lanthanide series.

Global Production of Praseodymium

The production of praseodymium is largely driven by the demand for rare earth elements in various high-tech industries. According to industry reports, the production of praseodymium is closely tied to the broader rare earth supply chain, which includes the mining and processing of ores such as monazite and bastnäsite.

Major Producers of Praseodymium

The production of praseodymium is concentrated in a few key countries, with China being by far the largest producer, controlling the majority of the global supply of rare earth elements. The main global producers of praseodymium include:

- China: As the world’s largest producer of rare earths, China dominates the supply of praseodymium. It is estimated that China accounts for around 60-70% of the global production of rare earth elements, including praseodymium.

- United States: The United States also produces praseodymium, particularly through the Mountain Pass Mine in California, which was reopened in recent years to meet growing global demand for rare earth elements.

- Australia: Australia is another significant producer of rare earth elements, including praseodymium, mainly from its Lynas Corporation operations.

- India: India has substantial reserves of monazite ore, which contains praseodymium, although its production levels remain lower compared to China and the United States.

- Russia: Russia is also a notable player in the rare earth market, with growing investments in rare earth mining and production capabilities.

Extraction and Refining Process

Praseodymium is primarily extracted from rare earth ore deposits, such as bastnäsite and monazite. The extraction process involves several stages:

- Mining: Rare earth minerals are extracted from the earth using conventional mining methods, including open-pit mining and underground mining.

- Crushing and Milling: The mined ore is crushed and ground into fine particles to facilitate the extraction of praseodymium and other rare earth elements.

- Separation: The next step involves separating the praseodymium from other elements through chemical processes, such as solvent extraction or ion-exchange. This helps isolate praseodymium and other valuable rare earth elements.

- Refining: The final refining process produces high-purity praseodymium, which is typically available in the form of praseodymium oxide (Pr₂O₃) or praseodymium metal.

Applications of Praseodymium

Praseodymium has several important applications across various industries, particularly due to its unique magnetic, optical, and chemical properties. Some of the major uses of praseodymium include:

- Alloys and Magnets: Praseodymium is used to create high-strength alloys for use in aircraft engines and other aerospace applications. It is also used in the manufacture of powerful permanent magnets for motors, hard disk drives, and electric vehicles.

- Catalysts: Praseodymium compounds are used as catalysts in various chemical processes, including the production of petrochemicals and hydrogenation.

- Glass and Ceramics: Praseodymium is used to color glass and ceramics, giving them a yellow-green tint. It is also used in optical lenses.

- Phosphors and Lighting: Praseodymium is used in the production of phosphors for fluorescent lamps and energy-efficient lighting. It is also used in color television tubes and LEDs.

- Batteries: Praseodymium plays a role in nickel-metal hydride (NiMH) batteries, which are used in electric vehicles and portable electronics.

Challenges and Future Outlook

Despite its relatively abundant supply in the Earth’s crust, the production and supply of praseodymium face several challenges:

- Concentration in China: China’s dominance in the praseodymium production sector poses potential risks for global supply chains, especially if geopolitical tensions or trade restrictions arise.

- Environmental Concerns: The extraction and processing of praseodymium and other rare earth elements are environmentally intensive processes, with concerns regarding radioactive byproducts and pollution.

- Recycling: Increasing the recycling of praseodymium from used electronics, magnets, and batteries could reduce the reliance on mining and mitigate environmental impacts.

Conclusion

Praseodymium is a critical element in many modern technologies, from energy storage to aerospace engineering. Its abundance in the Earth’s crust, especially compared to other rare earth elements, offers opportunities for widespread use. However, the global production of praseodymium remains concentrated in a few countries, with China controlling a significant portion of the supply.

As the demand for rare earth elements continues to grow, sustainable production methods and recycling initiatives will play an essential role in ensuring the continued availability of praseodymium for its diverse applications.