Monolayer Graphene on SiO2/Si Substrate: Properties, Fabrication, and Applications

Graphene, a single layer of carbon atoms arranged in a honeycomb lattice, has captured the attention of researchers and industries alike due to its exceptional electrical, thermal, and mechanical properties. One of the most widely studied configurations for fabricating graphene is by growing it on a SiO2/Si (Silicon Dioxide/Silicon) substrate. This combination has proven to be essential in both academic research and practical applications, especially in electronics and nanoelectronics.

In this article, we will explore the properties of monolayer graphene grown on SiO2/Si substrates, the methods used for its fabrication, and the applications that benefit from this combination.

What is Monolayer Graphene?

Monolayer graphene refers to a single layer of carbon atoms bonded in a two-dimensional hexagonal lattice. Unlike multi-layer graphene, which consists of several graphene sheets stacked on top of each other, a monolayer graphene structure exhibits unique electrical, mechanical, and thermal properties that make it a promising material for a wide range of nanoelectronic applications.

Key characteristics of monolayer graphene include:

- Exceptional Electrical Conductivity: Monolayer graphene has a high carrier mobility (up to 15,000 cm²/V·s) at room temperature, making it an ideal candidate for high-speed transistors and other electronic devices.

- Mechanical Strength: It has extraordinary tensile strength, being 100 times stronger than steel.

- Thermal Conductivity: Graphene exhibits high thermal conductivity, allowing it to efficiently dissipate heat.

- Transparency: It absorbs only about 2.3% of light, making it transparent and useful for applications in optics and photonics.

When grown on a SiO2/Si substrate, monolayer graphene can be integrated into various silicon-based technologies, leveraging the established infrastructure of semiconductor manufacturing.

SiO2/Si Substrate: A Popular Platform for Graphene Growth

The SiO2/Si substrate is commonly used as a supporting platform for growing graphene due to several reasons:

- Established Technology: Silicon wafers with a SiO2 (silicon dioxide) layer are already widely used in semiconductor industry processes. This makes it easier to integrate graphene with existing CMOS (complementary metal-oxide-semiconductor) technologies.

- Optical and Electrical Properties: The SiO2 layer serves as a dielectric layer, ensuring good insulation and providing the necessary conditions for the characterization of graphene’s electronic properties. Additionally, the Si substrate is transparent in the infrared region, enabling optical characterizations of graphene.

- Ease of Fabrication: SiO2/Si substrates are affordable and readily available, making them a cost-effective choice for large-scale graphene production.

Methods of Fabricating Monolayer Graphene on SiO2/Si Substrate

There are several methods used to fabricate monolayer graphene on SiO2/Si substrates, with the most popular techniques being chemical vapor deposition (CVD) and exfoliation methods.

1. Chemical Vapor Deposition (CVD)

CVD is the most widely used technique to grow high-quality monolayer graphene on SiO2/Si substrates. The process typically involves introducing gaseous carbon precursors (such as methane (CH4)) into a high-temperature reaction chamber, where the carbon atoms are deposited on the substrate. The key steps in the CVD process include:

- Heating the SiO2/Si substrate to high temperatures (typically between 900°C to 1100°C).

- Introducing a carbon-rich precursor gas (like methane) and hydrogen into the chamber.

- The carbon atoms from the precursor gas decompose and bond to form a monolayer graphene structure on the surface of the substrate.

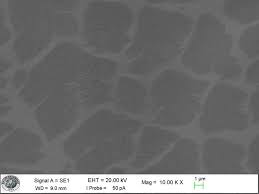

The quality of graphene grown using CVD on SiO2/Si is generally very high, with low defect density and large crystal size, which is ideal for use in electronics.

2. Mechanical Exfoliation (Scotch Tape Method)

While CVD offers high-quality graphene, mechanical exfoliation, commonly known as the Scotch tape method, is a simpler and more straightforward way to create monolayer graphene. In this method, graphite is mechanically peeled to produce thin layers of graphene, which can then be transferred onto a SiO2/Si substrate.

- Process: A piece of scotch tape is used to peel layers from a graphite sample. The resulting thin layers are then transferred onto the SiO2/Si substrate. This method is mainly used for research purposes, as it does not always yield large-area graphene films and may produce less uniformity compared to CVD.

3. Liquid-Phase Exfoliation

In this method, graphene oxide (GO) or graphite is dispersed in a liquid solvent and subjected to ultrasonic vibrations. The graphene sheets are separated and deposited onto the SiO2/Si substrate through drop-casting or spin-coating.

- Challenges: While this method is suitable for producing high-yield graphene, the graphene obtained is often non-uniform and requires further reduction processes to achieve high-quality monolayer graphene.

Properties of Monolayer Graphene on SiO2/Si Substrate

When monolayer graphene is transferred onto a SiO2/Si substrate, it retains many of its intrinsic properties, but the interaction with the underlying substrate also induces some changes in its behavior:

- Substrate Interaction: The SiO2 layer can slightly influence the electronic properties of graphene. For example, the charge carrier density and Fermi level of graphene can be modulated by the electric fields induced by the SiO2 substrate.

- Carrier Mobility: The carrier mobility of graphene grown on SiO2/Si substrates typically ranges from 10,000 cm²/V·s to 15,000 cm²/V·s. However, the presence of defects, contamination, and substrate interactions can reduce this value in practical devices.

- Optical Transparency: Since graphene is highly transparent, monolayer graphene on SiO2/Si retains its optical properties, making it useful in applications where transparent conductive films are needed.

- Mechanical Strength: Graphene retains its remarkable mechanical properties when transferred onto the SiO2/Si substrate, such as high tensile strength and flexibility, although the substrate itself may influence the overall flexibility of the device.

Applications of Monolayer Graphene on SiO2/Si Substrate

Monolayer graphene grown on SiO2/Si substrates has found applications across various fields, particularly in nanoelectronics, optoelectronics, and energy storage. Some of the most notable applications include:

1. Field-Effect Transistors (FETs)

Graphene’s high carrier mobility makes it an excellent candidate for high-speed transistors. Graphene field-effect transistors (GFETs), fabricated on SiO2/Si substrates, can potentially replace conventional silicon-based transistors in high-performance electronic circuits. The SiO2 layer acts as the gate dielectric, and the graphene acts as the conducting channel.

2. Transparent Conductive Films

Graphene is an excellent material for transparent conductive electrodes. On SiO2/Si substrates, graphene can be used for touchscreens, OLED displays, and solar cells. Its transparency combined with good conductivity makes it an attractive alternative to indium tin oxide (ITO) in flexible and transparent electronics.

3. Sensors and Biosensors

Monolayer graphene on SiO2/Si substrates is highly sensitive to changes in its environment, making it an ideal material for sensors. The high surface area and reactivity of graphene allow for the detection of gases, biomolecules, and other environmental changes at very low concentrations.

- Example: Graphene-based biosensors can detect biomarkers in biological fluids for medical diagnostics.

4. Photodetectors and Optoelectronic Devices

The electrical and optical properties of graphene make it a suitable material for photodetectors and optical modulators. When integrated on SiO2/Si substrates, graphene can detect light in a wide range of wavelengths, including infrared, making it useful in imaging systems and communication devices.

5. Energy Storage Devices

Monolayer graphene on SiO2/Si substrates is being explored for use in supercapacitors and batteries. Its high surface area, conductivity, and mechanical strength make it an ideal material for storing energy in energy-efficient devices.

Challenges and Future Directions

While monolayer graphene on SiO2/Si substrates shows great promise, several challenges still exist:

- Defects and Contamination: During the fabrication process, defects and impurities can affect the quality of graphene, reducing its performance in applications like transistors and sensors.

- Scalability: Large-scale production of high-quality monolayer graphene remains a challenge. While CVD offers good results for small areas, scaling it up for industrial applications is still under development.

- Integration: Integrating graphene into existing semiconductor technologies without compromising the performance of silicon devices requires careful design and fabrication techniques.

Future research will focus on improving fabrication techniques, enhancing the quality of graphene, and exploring new applications in fields such as quantum computing, biomedicine, and flexible electronics.

Conclusion

Monolayer graphene on SiO2/Si substrates represents a highly promising material platform for various electronic, optical, and energy applications. The combination of graphene’s exceptional properties and the established infrastructure of SiO2/Si substrates makes it an attractive candidate for next-generation nanoelectronic devices, transparent electronics, and sensors. As fabrication techniques improve and new applications emerge, the role of graphene in shaping the future of electronics and nanotechnology will continue to expand.