How to Sustainably Produce Nano Clays: A Comprehensive Guide to Green Synthesis and Applications

Nano clays are an emerging class of nanomaterials with significant potential in various industries, including plastics, electronics, medicine, and environmental protection. As demand for nano clays increases, the importance of sustainable and environmentally friendly production methods is growing. Traditional production methods can be energy-intensive and generate waste, which makes sustainable synthesis techniques an urgent area of research.

In this article, we will explore the sustainable production of nano clays, including green synthesis methods, their advantages, challenges, and future trends in the industry.

1. What Are Nano Clays?

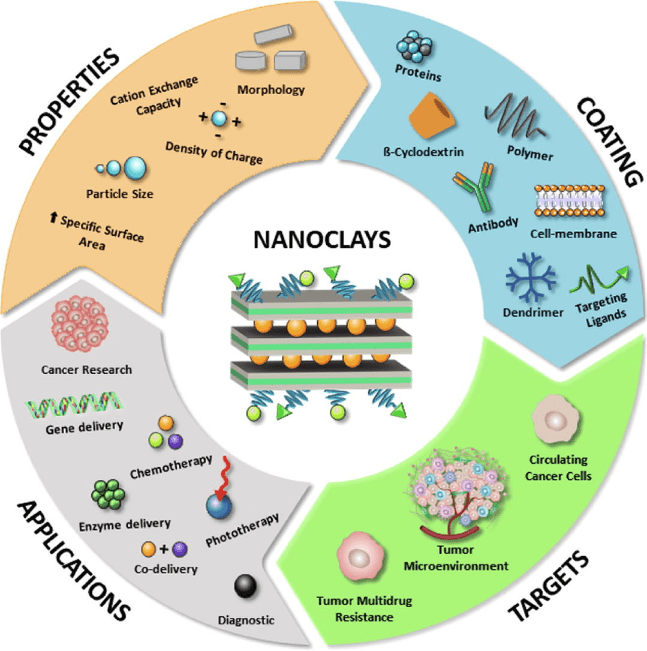

Nano clays are nano-sized particles derived from natural clay minerals, such as montmorillonite, kaolinite, smectite, and bentonite. These materials have a high surface area and layered structure, which give them unique properties, such as excellent adsorption, mechanical strength, and thermal stability. As nanomaterials, nano clays exhibit a wide range of functional properties, making them valuable in applications such as:

- Nanocomposites (for plastics, coatings, and electronics)

- Drug delivery systems in medicine

- Environmental remediation (e.g., water purification)

- Catalysis and filtration systems

2. Traditional Methods of Nano Clay Production

Conventional production techniques for nano clays involve top-down processes such as mechanical grinding, ball milling, and chemical exfoliation, which break larger clay particles into smaller, nano-sized ones. While these methods can be effective, they often have significant drawbacks, including:

- High energy consumption: Grinding and milling processes are energy-intensive.

- Chemical waste: The use of chemicals, especially in exfoliation, can generate harmful by-products.

- Material waste: These methods often result in a significant loss of material due to inefficient processing.

3. Sustainable Production Methods for Nano Clays

As the demand for sustainable production methods rises, researchers and industry players are increasingly turning to greener, more efficient techniques to produce nano clays. Some promising green synthesis methods include:

3.1. Biological Synthesis (Green Synthesis)

Biological synthesis, or green synthesis, uses natural materials such as microorganisms, plants, or biomolecules to synthesize nanoparticles. This process is more environmentally friendly, as it avoids the use of toxic chemicals and reduces energy consumption.

- Microbial Synthesis: Certain bacteria, fungi, and actinomycetes have been shown to naturally synthesize nano-sized clays by breaking down bulk clays or by producing enzymes that help exfoliate the layered structure of the clay. For example, some bacteria can enhance the exfoliation of montmorillonite by secreting specific enzymes that promote the separation of clay layers.

- Plant-Based Synthesis: Plants can also be used in the biomineralization process. By exposing plant extracts or plant residues to clay suspensions, nanoparticles can form through biosorption and bioreduction processes. Plant-derived compounds like polyphenols and flavonoids can act as reducing agents, reducing metal ions and promoting the synthesis of nano clays.

Advantages of Biological Synthesis:

- Non-toxic and eco-friendly: The use of natural resources eliminates harmful chemicals.

- Low energy requirements: Biological processes often occur at room temperature and under mild conditions, reducing energy consumption.

- Cost-effective: Using biomass or microorganisms is often more affordable than conventional chemical processes.

3.2. Hydrothermal Synthesis

Hydrothermal synthesis involves high-temperature water-based reactions in a sealed environment, such as an autoclave, to produce nanomaterials. This method can be used to synthesize nano clays directly from bulk clays by using a water-soluble alkaline solution or other solvents to exfoliate the clay layers.

- Low environmental impact: The process uses water as a solvent and can be done under mild conditions.

- High yield: Hydrothermal synthesis produces a large number of nanosheets with controlled sizes and properties.

Advantages of Hydrothermal Synthesis:

- Scalable: It can be applied on an industrial scale to produce nano clays in bulk.

- Eco-friendly solvents: Using water or green solvents reduces the need for hazardous chemicals.

- Customizable properties: The process allows for control over the particle size, morphology, and surface charge of the nano clays.

3.3. Microwave-Assisted Synthesis

Microwave-assisted synthesis uses microwave radiation to rapidly heat clay materials, promoting exfoliation and producing nano clays in a short period. This technique is gaining popularity due to its energy efficiency and speed compared to traditional methods.

- Faster processing times: Microwave heating reduces processing times by allowing more rapid heating of materials.

- Uniform heating: Microwaves heat materials uniformly, reducing the risk of thermal degradation and improving yield.

Advantages of Microwave-Assisted Synthesis:

- Energy-efficient: It significantly reduces energy consumption compared to conventional methods.

- Reduced environmental impact: It uses minimal or no solvents, reducing chemical waste.

- Controlled exfoliation: The technique allows for precise control over the size and distribution of the nano clays.

3.4. Sol-Gel Process

The sol-gel process involves the use of colloidal suspensions (sols) to form a gel, which is then dried and calcined to produce the desired nanomaterials. The sol-gel method is used for producing nano clays that are more uniform and well-dispersed in composite materials.

- Low temperature: The sol-gel process operates at relatively low temperatures (compared to traditional high-temperature methods), reducing energy consumption.

- Flexibility: The process can be adjusted to tailor the properties of the resulting nano clays.

Advantages of the Sol-Gel Process:

- Environmentally benign: The method often uses aqueous solutions and low-toxicity precursors.

- Versatile: It is adaptable to various types of clays and allows for the creation of nano composites.

4. Applications of Nano Clays

Sustainably produced nano clays have a wide range of applications across industries:

4.1. Polymer Nanocomposites

Nano clays are often incorporated into polymers to improve properties like mechanical strength, thermal stability, and barrier properties. These composite materials are used in the production of automotive parts, packaging, and construction materials.

4.2. Environmental Remediation

Nano clays have excellent adsorption properties, making them useful for water and soil remediation. They can be used to remove heavy metals, toxins, and organic pollutants from water.

4.3. Drug Delivery Systems

In the pharmaceutical industry, nano clays are used to develop drug delivery systems due to their ability to encapsulate and control the release of therapeutic agents.

4.4. Catalysis

Nano clays are used as catalysts or catalyst supports in a variety of chemical processes, including green chemistry applications. Their high surface area and active sites make them ideal for enhancing reaction rates.

5. Challenges and Considerations in Sustainable Nano Clay Production

Despite the advancements in green synthesis methods, there are still several challenges to overcome:

- Scalability: While lab-scale production of nano clays via green methods is promising, scaling these processes for industrial production is often difficult and may require further optimization.

- Cost: Some green methods, such as biological synthesis, may not yet be as cost-effective as traditional methods, though ongoing research is likely to reduce costs.

- Purity: Ensuring that the produced nano clays are free from impurities and consistent in quality is crucial for their use in high-performance applications.

6. Future Trends in Sustainable Nano Clay Production

The future of sustainable nano clay production is likely to involve a combination of biological synthesis, green chemistry, and advanced processing techniques. Research is focusing on:

- Improved scalability of green production methods for large-scale applications.

- Hybrid synthesis techniques, combining biological, hydrothermal, and microwave methods to achieve even more sustainable and cost-effective production processes.

- Developing new applications for nano clays in areas like energy storage, water filtration, and eco-friendly composites.

7. Conclusion

Sustainably producing nano clays represents a key challenge in the pursuit of greener and more efficient material production. Techniques like biological synthesis, hydrothermal synthesis, microwave-assisted synthesis, and sol-gel processes offer promising alternatives to traditional methods, reducing energy consumption and environmental impact. As research continues, the commercial viability of these techniques is expected to improve, enabling a more sustainable future for nano clay production and its wide array of applications across industries.