Graphene Sheet Films Applications: A Revolution in Technology and Industry

Introduction

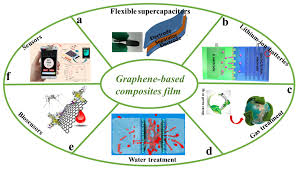

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is one of the most remarkable materials discovered in recent times. Since its isolation in 2004, graphene has sparked a revolution in various fields due to its exceptional properties, including high electrical conductivity, mechanical strength, and thermal conductivity. One of the most intriguing forms of graphene is graphene sheet films—thin, flexible sheets of graphene that retain many of these remarkable properties. These films are being actively researched and used in a wide array of industries, from electronics to energy, medicine, and beyond.

In this article, we explore the various applications of graphene sheet films, their benefits, and the potential they hold for future technological advancements.

1. Flexible and Transparent Electronics

Graphene sheet films are increasingly used in the production of flexible electronics. Their remarkable mechanical properties, including high flexibility, lightweight nature, and strength, make them ideal candidates for use in devices that need to be both bendable and conductive.

Applications in Flexible Electronics:

- Touchscreens: Graphene films can serve as transparent conductive films (TCFs) for touchscreen displays, offering an alternative to indium tin oxide (ITO), which is brittle and expensive.

- OLED Displays: Graphene’s high conductivity and flexibility make it a great material for the transparent electrodes in organic light-emitting diodes (OLEDs).

- Wearable Electronics: Graphene sheet films can be integrated into wearables, such as fitness trackers, health-monitoring devices, and smart clothing. The film’s flexibility allows it to conform to the body, while its electrical conductivity enables the integration of sensors and power sources.

- Flexible Solar Cells: Graphene films are being explored in photovoltaic cells, especially flexible solar panels, which are lightweight and durable, offering the potential to integrate solar power generation into portable devices or clothing.

Benefits:

- High flexibility and transparency.

- Lightweight, which is critical for portable electronics.

- Low electrical resistance and high conductivity, ensuring efficient energy transfer.

2. Energy Storage and Supercapacitors

Graphene sheet films have made significant strides in energy storage technologies, particularly in the development of supercapacitors and batteries. Supercapacitors, in particular, benefit from graphene’s high surface area and conductivity, allowing for the storage of a larger amount of energy in a smaller space.

Applications in Energy Storage:

- Supercapacitors: Graphene-based supercapacitors can charge and discharge much faster than traditional capacitors and batteries, offering advantages in power density and cycle life. These devices are essential for applications requiring rapid energy bursts, such as in electric vehicles (EVs) or renewable energy systems.

- Batteries: Graphene films are used in lithium-ion batteries, particularly in the anode or cathode materials. The conductive nature of graphene enhances the charge-discharge cycle and improves the battery’s energy density.

- Energy Harvesting: Graphene’s flexibility and conductivity make it an ideal material for energy harvesting devices, where it can capture energy from environmental sources like vibration, heat, or solar radiation.

Benefits:

- Higher charge-discharge efficiency.

- Enhanced storage capacity in smaller and more flexible formats.

- Potential for longer-lasting energy storage solutions.

3. Sensors and Environmental Monitoring

Graphene sheet films can also be used to develop sensors for detecting a wide range of chemical, biological, and environmental factors. The high surface area of graphene allows it to interact strongly with various molecules, making it an ideal candidate for creating sensitive, fast-response sensors.

Applications in Sensors:

- Gas Sensors: Graphene films can be used in the detection of toxic gases or air pollutants, such as carbon dioxide (CO2), nitrogen dioxide (NO2), and ammonia (NH3). Their high sensitivity and rapid response time make graphene-based gas sensors highly efficient.

- Biosensors: Graphene sheets are used in the development of biosensors that can detect specific biomarkers, enabling faster and more sensitive diagnostic tools. These sensors can be used for medical diagnostics or in environmental monitoring to detect contaminants.

- Chemical Sensors: Graphene sheet films are also used for detecting harmful chemicals in water or air. Their ability to modify their electronic properties upon exposure to specific chemicals allows for highly sensitive detection.

Benefits:

- High sensitivity to chemical and biological agents.

- Faster response times compared to traditional sensor technologies.

- Compact and flexible, suitable for portable and wearable sensor devices.

4. Biomedical Applications

The biomedical industry is one of the most exciting fields in which graphene sheet films are showing significant promise. Due to their biocompatibility, high surface area, and ability to functionalize for specific tasks, graphene sheet films are finding use in a wide range of medical applications.

Applications in Biomedical Fields:

- Drug Delivery: Graphene-based materials, including graphene sheet films, are used in drug delivery systems. Their large surface area allows them to carry drug molecules and release them in a controlled manner. This is particularly beneficial for targeting specific tissues or organs, such as tumor cells in cancer therapy.

- Tissue Engineering: Graphene films are being investigated as scaffolds in tissue engineering. Their structural properties can be tailored to mimic the extracellular matrix, providing a supportive environment for cell growth and tissue regeneration.

- Wound Healing: Graphene’s antibacterial properties and biocompatibility make it useful for wound dressings. Graphene-based films can accelerate the healing process by promoting cell growth and protecting the wound from infections.

- Biosensors: In addition to chemical and environmental sensors, graphene sheet films are used in medical diagnostics. They can be functionalized to detect disease markers and provide real-time health monitoring, such as blood glucose levels or cancer biomarkers.

Benefits:

- Biocompatible, reducing the risk of rejection or side effects.

- Highly customizable for drug delivery, tissue regeneration, and diagnostic applications.

- Antibacterial properties, making them ideal for medical device coatings and wound healing.

5. Water Purification and Desalination

Graphene sheet films are also making strides in water treatment technologies, including desalination and water purification. Their high surface area, combined with the ability to create nanoporous structures, makes graphene ideal for filtering and separating substances at the molecular level.

Applications in Water Purification:

- Desalination: Graphene oxide membranes have shown promise in desalination, where they can filter out salt ions from seawater. These membranes offer high selectivity and permeability, making them more efficient than traditional desalination methods.

- Water Filtration: Graphene sheets can be used in water filters to remove organic contaminants, heavy metals, and bacteria. Their ability to be functionalized with antibacterial agents further enhances their filtration capabilities.

- Pollutant Removal: Graphene films are capable of adsorbing toxic pollutants and chemical contaminants from water, providing a sustainable solution to global water pollution issues.

Benefits:

- High filtration efficiency.

- Cost-effective and sustainable water purification.

- Enhanced selectivity for ions and molecules, improving overall performance.

Challenges and Future Outlook

While graphene sheet films show immense potential across these various applications, there are still challenges to overcome in order to fully harness their capabilities. Some of the key challenges include:

- Scalability: Producing graphene sheet films on a large scale with consistent quality remains a significant challenge. Advances in production techniques, such as chemical vapor deposition (CVD) or liquid-phase exfoliation, are essential for scaling up graphene manufacturing.

- Cost: The production of high-quality graphene sheets is still relatively expensive, limiting their widespread adoption in commercial products.

- Long-term stability: The long-term stability of graphene-based materials in certain environments, such as in biological systems or harsh industrial conditions, needs further investigation.

Despite these challenges, ongoing research and development in graphene-based technologies are likely to overcome these hurdles, leading to more widespread and cost-effective applications in the future.

Conclusion

Graphene sheet films are poised to revolutionize a range of industries, from electronics and energy storage to healthcare and water purification. Their combination of flexibility, conductivity, strength, and biocompatibility makes them ideal candidates for a wide range of applications, offering significant advancements in technology and sustainability. As research into graphene continues to progress, we can expect even more innovative uses of graphene sheet films, driving progress in next-generation electronics, medical devices, and environmental technologies.