Strategies for Improving Rechargeable Lithium-Ion Batteries

Introduction

Rechargeable lithium-ion (Li-ion) batteries have revolutionized energy storage and become the dominant power source for devices ranging from smartphones and laptops to electric vehicles (EVs) and renewable energy storage systems. Despite their success, Li-ion batteries still face several challenges, including limited energy density, degradation over time, long charging times, and safety concerns. As demand for higher performance and longer-lasting batteries continues to grow, researchers, manufacturers, and engineers are developing innovative strategies to improve the performance, efficiency, and safety of lithium-ion batteries.

This article explores various strategies being pursued to enhance rechargeable lithium-ion batteries, focusing on advancements in materials, battery design, charging technology, and other areas that could contribute to the next generation of Li-ion batteries.

1. Enhancing Energy Density

Increasing the energy density of lithium-ion batteries is one of the most critical goals for improving their performance. Energy density determines how much energy a battery can store for a given size and weight, and higher energy density enables longer battery life and more efficient power delivery. Some of the strategies for enhancing energy density include:

a. Silicon Anodes

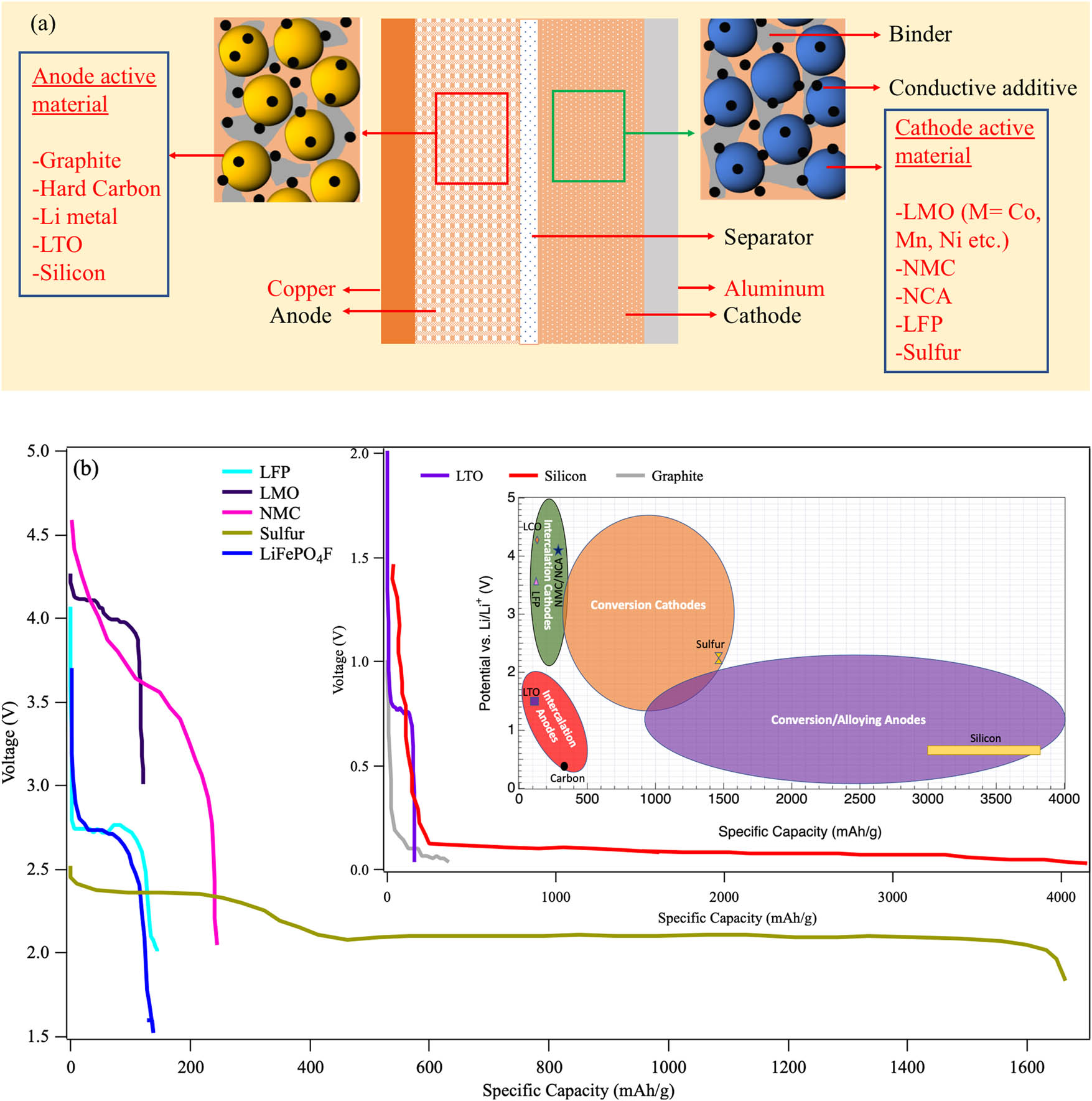

Traditional lithium-ion batteries use graphite as the anode material, which has a relatively low capacity for storing lithium ions. Silicon has the potential to significantly increase the energy density because it can hold more lithium ions compared to graphite. However, silicon expands and contracts during charge and discharge cycles, which leads to material degradation and loss of capacity.

Strategies to improve silicon anodes:

- Nano-structuring silicon: By breaking silicon into nanoscale particles or using silicon nanowires, researchers are able to minimize the volume expansion problem and enhance the material’s stability.

- Silicon-graphene composites: Combining silicon with graphene can help mitigate the expansion issue while benefiting from the high conductivity and strength of graphene.

- Silicon oxide: Silicon oxide can be used as a more stable form of silicon, though it has a lower capacity than pure silicon.

b. High-Voltage Cathodes

While the anode material is crucial, the cathode material also plays a significant role in determining the energy density of Li-ion batteries. Traditional cathodes, such as lithium cobalt oxide (LiCoO2), have limited voltage stability. High-voltage cathodes like nickel-cobalt-aluminum (NCA) and nickel-manganese-cobalt (NMC) alloys are being developed to enable batteries to operate at higher voltages, thus increasing energy density.

New Cathode Materials:

- Lithium-rich layered oxide cathodes: These cathodes can provide higher voltages and enhance the overall energy density.

- High-nickel cathodes: These materials offer improved energy storage capabilities by increasing the amount of nickel in the cathode, which results in higher capacity and power output.

c. Solid-State Batteries

Solid-state batteries replace the liquid electrolyte used in traditional lithium-ion batteries with a solid electrolyte, which improves both the energy density and safety of the battery. Solid-state batteries can utilize higher-energy materials, such as lithium metal anodes, which can significantly increase energy density compared to conventional graphite anodes.

- Challenges to overcome: Solid-state batteries require high ionic conductivity in the solid electrolyte, and there are issues related to manufacturing scalability and cost.

2. Improving Battery Longevity and Cycle Life

Battery longevity, or cycle life, is an essential factor in the performance of rechargeable lithium-ion batteries. Over time, repeated charge and discharge cycles degrade the materials in the battery, leading to reduced capacity and shortened battery life. Strategies to extend battery lifespan include:

a. Enhancing Electrolyte Stability

The electrolyte is one of the most critical components of lithium-ion batteries, and its degradation over time is a major cause of capacity fade. Researchers are exploring new electrolyte materials that offer greater stability and resilience, such as:

- Solid electrolytes that prevent dendrite formation and improve safety.

- Ionic liquids and gel polymer electrolytes, which can provide better thermal stability and prevent the formation of harmful by-products during cycling.

b. Improving Battery Management Systems (BMS)

An advanced Battery Management System (BMS) can optimize the charging and discharging process, helping to balance the cells and prevent overcharging or deep discharging, which can damage the battery. Modern BMS can use algorithms and sensors to:

- Monitor battery temperature, voltage, and current.

- Equalize charge between cells in a battery pack.

- Predict and prevent degradation, thereby improving overall battery lifespan.

c. Advanced Coatings for Electrodes

The surfaces of electrodes are prone to degradation over time due to side reactions with the electrolyte, particularly at high voltages. Protective coatings on electrodes can help enhance their cycle stability. For example:

- Lithium phosphate coatings can improve the stability of the anode.

- Nanocoatings can prevent oxidation and reduce the rate of material degradation on the cathode and anode.

d. High-Performance Graphene Composites

Graphene is a highly conductive material that can be used as a coating or composite material for both the anode and cathode. When incorporated into battery materials, graphene can improve the mechanical properties, conductivity, and structural integrity of the electrodes, leading to better cycle stability and longer battery life.

3. Enhancing Charging Speed

The charging speed of lithium-ion batteries is a crucial factor for user convenience, especially in electric vehicles and portable electronics. Strategies to reduce charging times and improve efficiency include:

a. High-Conductivity Electrolytes

Faster charging requires more efficient movement of lithium ions through the electrolyte. Research into high-conductivity electrolytes aims to speed up the charging process. These include:

- Gel polymer electrolytes that facilitate faster ion diffusion.

- Ionic liquid-based electrolytes that can maintain high conductivity even at lower temperatures.

b. Advanced Charging Protocols

Developing advanced charging protocols can also play a crucial role in reducing charging times without compromising battery health. Techniques like pulsed charging and constant current charging can accelerate the process by optimizing ion movement and preventing overheating during fast charging.

c. Silicon Nanostructures

Nanostructuring silicon, as mentioned earlier, can not only improve energy density but also increase the rate at which lithium ions can move in and out of the anode material. This facilitates faster charging without significant loss in capacity or safety.

4. Improving Battery Safety

Safety remains a primary concern for lithium-ion batteries, particularly in applications like electric vehicles and consumer electronics. Overcharging, short circuits, and thermal runaway can cause fires or explosions. Strategies to improve safety include:

a. Solid-State Electrolytes

As mentioned, solid-state electrolytes are non-flammable and offer superior thermal stability compared to liquid electrolytes. These electrolytes significantly reduce the risks of thermal runaway and fire hazards in the event of mechanical damage or overcharging.

b. Thermal Management Systems

Implementing efficient thermal management systems can help maintain battery temperatures within safe limits. Innovations in cooling technologies, including liquid cooling or phase-change materials, can ensure that batteries in high-demand applications like electric vehicles remain safe during prolonged use.

c. Battery Design for Safety

Designing batteries with inherent safety features, such as safety vents, shutdown separators, and pressure relief mechanisms, can help prevent accidents. These features ensure that in the event of an internal fault, the battery can safely vent gases or shut down before catastrophic failure occurs.

5. Sustainable and Scalable Manufacturing

Finally, improving the sustainability and scalability of lithium-ion battery production is essential for the widespread adoption of next-generation battery technologies. Key strategies include:

a. Recycling and Reuse

Developing more efficient battery recycling methods can reduce the need for raw materials like cobalt and lithium. Recycling technologies that recover high-value metals and components can help reduce the environmental impact of battery production and make the supply chain more sustainable.

b. Green Materials and Manufacturing Techniques

Using eco-friendly materials and low-energy manufacturing techniques can reduce the carbon footprint of lithium-ion battery production. Researchers are working on new processes to minimize waste, reduce the need for toxic solvents, and improve the recyclability of battery components.

Conclusion

Improving rechargeable lithium-ion batteries involves a multifaceted approach that includes enhancing energy density, longevity, charging speed, and safety while also ensuring sustainability in the manufacturing process. From advances in silicon anodes and solid-state electrolytes to more efficient battery management systems and novel manufacturing techniques, these innovations are helping push the boundaries of what lithium-ion batteries can achieve.

As research continues and commercial applications evolve, we can expect significant improvements in battery performance, which will play a critical role in the future of electric vehicles, renewable energy storage, and a variety of consumer electronics. The progress made in improving lithium-ion batteries will be a key driver in the transition to a more sustainable, energy-efficient future.