Applications of Silicon Rubbers in Nanotechnology

Silicon rubber, often referred to as silicone rubber, is a versatile and highly durable material that has become indispensable in various industries, including the rapidly evolving field of nanotechnology. Known for its flexibility, heat resistance, and electrical insulating properties, silicon rubber finds applications in a variety of nanotech-based devices and systems. These unique attributes are particularly advantageous in the development of nanoelectronics, nanomaterials, sensors, and other advanced technologies.

This article explores the various applications of silicon rubbers in nanotechnology, highlighting their role in the design of nano-devices, nano-sensors, and advanced coatings, as well as their contribution to biomedical and energy applications.

1. What is Silicon Rubber?

Silicon rubber is a synthetic elastomer made from silicon-based polymers, specifically polysiloxanes. These polymers consist of repeating units of silicon-oxygen (Si-O) bonds, giving the material its unique properties:

- Thermal stability: Silicone rubber remains stable and flexible across a wide temperature range, typically from -50°C to 250°C.

- Electrical insulation: It offers excellent electrical insulating properties.

- Flexibility: Silicon rubber is highly flexible and can be molded into various shapes without losing its structural integrity.

- Chemical resistance: It is resistant to many chemicals, making it suitable for harsh environments.

Because of these features, silicon rubber is widely used in industries ranging from automotive to medical devices. However, in the context of nanotechnology, its unique characteristics are leveraged for innovations in nanoelectronics, sensors, biomedical devices, and energy applications.

2. Applications of Silicon Rubber in Nanotechnology

a. Nanomaterial Synthesis and Template Development

Silicon rubber is utilized in nanomaterial synthesis and as a template for the fabrication of nanostructures. Its flexibility and moldability allow it to serve as an excellent medium for the creation of complex nanostructures with high precision.

- Nanoparticle Patterning: Silicon rubber is used to mold and pattern nanoparticles. For instance, it can be employed in soft lithography to imprint nanoscale patterns on substrates, facilitating the production of nanoelectronic devices and photonic crystals.

- Nano-coatings: Silicone rubber-based materials are used to coat and protect nanostructures in various devices. The material’s flexibility and ability to withstand high temperatures make it ideal for use in nanotechnology applications that involve extreme environmental conditions.

- Nanostructure Templates: By creating flexible molds from silicone rubber, researchers can fabricate nanostructures like nanowires, nanotubes, and nanorods with high precision, which are then used in nanoelectronics, energy harvesting systems, and biosensors.

b. Nanoelectronics and Flexible Electronics

Silicon rubber’s flexibility, electrical insulating properties, and thermal resistance make it an ideal material for use in the nanoelectronics sector. The ability to create stretchable and flexible circuits opens new possibilities for wearable electronics, flexible displays, and smart sensors.

- Flexible Printed Circuits: Silicone rubber is used to create flexible substrates for printed circuit boards (PCBs), which are foundational for nanoelectronics. These flexible circuits can be used in wearable electronics, foldable displays, and bioelectronics.

- Flexible Sensors: Silicon rubber-based sensors can be embedded into soft, stretchable materials, enabling the creation of sensors that can conform to the human body or other irregular surfaces. This is particularly useful in health monitoring systems, wearable devices, and smart textiles.

c. Nanostructured Coatings and Surface Modifications

In nanotechnology, coatings and surface modifications are essential for enhancing material properties such as durability, adhesion, biocompatibility, and conductivity. Silicon rubber, with its ability to form uniform, high-performance coatings, is extensively used for this purpose.

- Self-Cleaning Surfaces: Silicon rubber-based coatings can be functionalized with nanostructures such as nano-porous surfaces or hydrophobic coatings, leading to the development of self-cleaning surfaces. This is used in nanomaterial protection and nano-optical devices.

- Anti-Fouling Coatings: Silicon rubber’s resistance to water and its anti-fouling properties are useful in biomedical applications where surfaces are exposed to bacteria, fungi, or marine environments. This property is used in medical implants, nano-robotics, and sensor surfaces that require high biocompatibility and long-lasting performance.

d. Nano-Sensors for Biomedical Applications

Silicon rubber’s flexibility, biocompatibility, and chemical resistance make it an excellent choice for use in nanobiotechnology and biomedical applications. The use of silicone rubber in nano-sensors is particularly significant in the fields of healthcare, diagnostics, and biosensing.

- Biosensors for Disease Detection: Silicone rubber-based sensors are used to detect biomarkers for diseases, including cancer, diabetes, and infection. These sensors can be integrated into wearable devices, allowing continuous monitoring of various physiological parameters.

- Implantable Medical Devices: Due to its biocompatibility and flexibility, silicon rubber is used in the development of implantable sensors and devices such as artificial organs and neuroprosthetics. These devices need to maintain flexibility while interfacing with biological systems for long periods without causing irritation or damage.

- Nanostructured Electrodes: Silicon rubber is employed to create nanostructured electrodes that are used in electrochemical biosensors, neuroelectronic interfaces, and drug delivery systems.

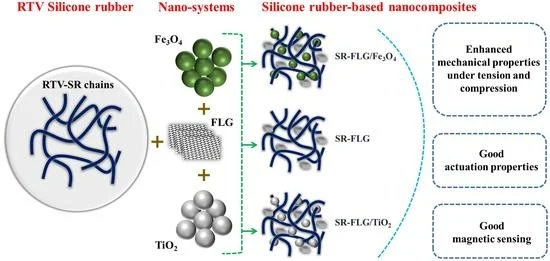

e. Nanocomposites for Enhanced Performance

In nanotechnology, nanocomposites—materials made by embedding nanomaterials into a matrix of silicon rubber—offer significant improvements in material properties such as strength, conductivity, and thermal stability. Silicon rubber is often used as the matrix material in these nanocomposites.

- Conductive Nanocomposites: Silicon rubber composites can be embedded with carbon nanotubes (CNTs), graphene, or metal nanoparticles to enhance their electrical conductivity. These materials are used in flexible electronics, strain sensors, and supercapacitors.

- Thermal Conductivity: By adding nanoparticles such as graphene or boron nitride to silicone rubber, the thermal conductivity of the material can be significantly enhanced. These nanocomposites are used in thermal management systems, especially in nanoelectronics and energy storage systems.

f. Energy Harvesting and Storage Systems

Silicon rubber plays an essential role in energy harvesting technologies, particularly in nanogenerators and energy storage devices. When combined with nanomaterials, silicon rubber can contribute to the development of high-efficiency energy devices.

- Flexible Piezoelectric Devices: Silicon rubber can be used in combination with piezoelectric nanomaterials to create flexible energy harvesting devices. These devices convert mechanical energy (from motion or pressure) into electrical energy and are used in wearable electronics and smart fabrics.

- Flexible Batteries and Supercapacitors: Silicon rubber can be used to encapsulate flexible batteries and supercapacitors, protecting them while maintaining flexibility. These devices are used in wearable energy storage systems, which need to be lightweight, flexible, and capable of high power density.

3. Challenges and Future Directions

While silicon rubber offers many advantages in nanotechnology applications, there are some challenges that need to be addressed:

- Material Durability: Over time, silicon rubber can suffer from wear and tear, particularly under extreme conditions. Research is focused on improving its longevity and resilience when used in nanoelectronics and biomedical devices.

- Optimization of Nanocomposites: The performance of silicon rubber nanocomposites can be highly dependent on the uniform distribution of nanoparticles. Future developments may focus on improving the dispersion and integration of nanoparticles within the rubber matrix.

- Cost and Scalability: While the use of silicon rubber in nanotechnology is promising, the cost and scalability of producing high-quality silicon rubber nanocomposites for large-scale applications need further optimization.

4. Conclusion

Silicon rubber plays a crucial role in nanotechnology, providing solutions in nanoelectronics, biomedical applications, energy harvesting, and sensors. Its unique properties, such as flexibility, thermal stability, and electrical insulating capabilities, make it an indispensable material for the development of cutting-edge nanodevices. As nanotechnology continues to advance, the demand for high-performance, versatile materials like silicon rubber will only increase, driving innovations in a variety of industries.