Applications of Hydrothermal Synthesis Autoclave Reactors

Hydrothermal synthesis is a widely used technique in materials science and chemistry for producing a variety of materials under high temperature and pressure conditions. This process, conducted in an autoclave reactor, is essential for creating materials such as nanomaterials, ceramics, semiconductors, and advanced catalysts. Hydrothermal synthesis allows for the formation of substances that are difficult to create through traditional methods, making it a vital technique in the development of novel materials with unique properties. In this article, we will explore the applications of hydrothermal synthesis and the role of autoclave reactors in producing a wide range of materials.

1. What is Hydrothermal Synthesis?

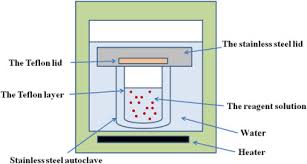

Hydrothermal synthesis involves the reaction of materials in water or aqueous solutions at elevated temperatures and pressures, typically above 100°C and up to several hundred degrees Celsius. The autoclave reactor used for this process is a sealed vessel designed to withstand high pressures and temperatures, facilitating the creation of substances under controlled conditions. This method mimics the natural formation of minerals and crystals deep within the Earth but accelerates the process.

Key parameters in hydrothermal synthesis include:

- Temperature: Typically between 100°C and 500°C.

- Pressure: Often ranging from 1 to 50 MPa.

- Solution Composition: The chemical composition of the precursor materials and solvent (usually water) plays a significant role in the synthesis process.

2. Applications of Hydrothermal Synthesis in Material Science

a. Nanomaterials and Nanostructures

Hydrothermal synthesis is widely used to fabricate nanomaterials, such as nanoparticles, nanorods, nanosheets, and nanotubes. These nanomaterials have unique properties, including high surface area, excellent electrical conductivity, and enhanced catalytic activity, making them suitable for various applications:

- Catalysts: Hydrothermal synthesis can be used to create nanocatalysts for chemical reactions. These catalysts are vital in industries like petroleum refining, environmental remediation, and green chemistry.

- Photocatalysis: Titanium dioxide (TiO₂) and zinc oxide (ZnO) nanoparticles, synthesized via hydrothermal methods, are commonly used in photocatalytic applications like water splitting, degradation of pollutants, and solar energy conversion.

- Battery Materials: Hydrothermal processes are employed to produce high-performance anode and cathode materials for lithium-ion batteries, sodium-ion batteries, and supercapacitors.

b. Ceramics and Semiconductors

Hydrothermal synthesis is a preferred method for producing ceramic materials and semiconductors with excellent purity and controlled crystallinity. This process is essential in fields such as electronics, optics, and energy storage:

- Semiconductor Materials: Hydrothermal synthesis is used to create materials like cadmium sulfide (CdS), zinc oxide (ZnO), and titanium dioxide (TiO₂), which are crucial for applications in photovoltaic cells, light-emitting diodes (LEDs), and photoelectrochemical cells.

- Ceramics: High-quality ceramic powders are synthesized through hydrothermal methods for use in applications like dielectrics, piezoelectric devices, and electroceramics.

c. Batteries and Supercapacitors

The production of advanced materials for batteries and supercapacitors is another critical application of hydrothermal synthesis. Materials like LiFePO₄ (lithium iron phosphate), MnO₂ (manganese dioxide), and graphene oxide are synthesized using hydrothermal methods to enhance the performance and efficiency of energy storage devices:

- Lithium-Ion Batteries: Hydrothermal synthesis is used to create cathode materials with high conductivity and charge storage capacity, improving battery performance.

- Supercapacitors: The creation of high-surface-area activated carbon and carbon-based nanomaterials via hydrothermal methods improves energy density and charge/discharge rates for supercapacitors.

d. Advanced Polymers and Composites

Hydrothermal synthesis is increasingly being employed to produce advanced polymers and polymer composites with superior mechanical, thermal, and chemical properties. These materials find applications in industries ranging from automotive to aerospace.

- Polymeric Nanocomposites: The process can synthesize nanoclay-reinforced composites, improving mechanical strength and thermal stability for use in high-performance materials.

- Hydrogels: Hydrothermal methods are used to create crosslinked hydrogels, which are crucial in biomedical and environmental applications such as drug delivery, tissue engineering, and water treatment.

e. Environmental Remediation and Wastewater Treatment

Hydrothermal synthesis plays a key role in producing adsorbents and catalysts for environmental applications. These materials can be used for removing contaminants, recycling waste materials, and treating wastewater:

- Heavy Metal Removal: Hydrothermal methods are employed to synthesize adsorbents such as activated carbon and biochar, which effectively remove heavy metals and other pollutants from water.

- Pollutant Degradation: Photocatalysts like TiO₂ synthesized via hydrothermal methods are used for degradation of organic pollutants in wastewater.

f. Catalysis and Green Chemistry

The ability to create highly pure, high-surface-area materials makes hydrothermal synthesis a vital technique for the development of catalysts used in green chemistry and sustainable processes:

- Zeolites: Hydrothermal synthesis is commonly used to produce zeolites, which are crucial for catalytic applications such as oil refining and gas separation.

- Nanocatalysts: These catalysts, synthesized hydrothermally, exhibit excellent activity for a wide range of chemical reactions, including hydrogenation, oxidation, and environmental cleanup.

g. Biomaterials and Pharmaceuticals

Hydrothermal methods are increasingly used to create biomaterials and pharmaceuticals, thanks to their ability to produce materials with precise structures and excellent purity:

- Bioceramics: Hydrothermal synthesis is used to produce bioceramics for bone grafts, dental implants, and drug delivery systems.

- Pharmaceuticals: Certain drug molecules and active pharmaceutical ingredients (APIs) can be synthesized using hydrothermal methods, ensuring high purity and consistent quality.

3. Advantages of Hydrothermal Synthesis Using Autoclave Reactors

Hydrothermal synthesis in autoclave reactors offers several advantages that make it a preferred method for producing high-performance materials:

- Controlled Environment: Autoclaves allow precise control of temperature, pressure, and reaction time, enabling the formation of high-quality products with well-defined properties.

- Energy Efficiency: The process is often more energy-efficient compared to traditional methods because reactions can occur at relatively lower temperatures and shorter times, thanks to the high pressure.

- Material Versatility: Hydrothermal synthesis can produce a wide variety of materials, including metals, ceramics, and polymers, allowing for flexibility in industrial applications.

- Enhanced Reaction Rates: The high pressure inside the autoclave reactor accelerates reaction rates, leading to faster production of desired materials.

4. Challenges in Hydrothermal Synthesis

Despite the numerous benefits, there are also several challenges associated with hydrothermal synthesis:

- Material Selection: Finding suitable precursor materials that can withstand the high-pressure and high-temperature conditions inside the autoclave is essential for successful synthesis.

- Scalability: Scaling up hydrothermal synthesis processes for industrial-scale production can be challenging, particularly when dealing with expensive or complex materials.

- Reactor Design: The design of the autoclave reactor needs to accommodate the specific requirements of different materials, such as pressure and temperature tolerances, while ensuring safety.

5. Future Directions in Hydrothermal Synthesis

With continuous advancements in material science, hydrothermal synthesis is expected to play an even greater role in the future:

- Integration with Green Chemistry: The development of more sustainable hydrothermal processes is likely, focusing on reducing the environmental impact of material synthesis.

- Advanced Functional Materials: Hydrothermal methods will continue to be used for creating advanced functional materials for applications in electronics, photovoltaics, sensors, and biomaterials.

- Nanomaterial Design: Future research may focus on the precise control of nanomaterial properties (e.g., size, shape, and crystallinity), enabling the creation of even more efficient catalysts and materials for energy storage.

6. Conclusion

Hydrothermal synthesis in autoclave reactors is a versatile and powerful technique with broad applications across various industries. From nanomaterials and semiconductors to energy storage and environmental applications, hydrothermal synthesis enables the creation of materials with unique properties that would be challenging to obtain through other methods. As the technology advances, we can expect continued growth in its applications, particularly in the fields of green chemistry, biomaterials, and advanced electronics. While challenges remain, the advantages of this method ensure its continued importance in material science and industrial production.