2 Best Ways to Synthesize Carbon Nanotubes (CNTs)

Carbon Nanotubes (CNTs) are cylindrical nanostructures made up of carbon atoms arranged in a hexagonal lattice. Known for their exceptional properties, including high tensile strength, electrical conductivity, and thermal stability, CNTs have emerged as one of the most promising materials for applications in electronics, energy storage, biomedical devices, and nanocomposites. However, to harness the potential of CNTs, it’s essential to use effective synthesis methods that allow for control over their properties, such as diameter, length, and chirality. Below are the two best methods for synthesizing carbon nanotubes, each with its advantages and unique capabilities:

1. Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is widely regarded as one of the most effective and scalable methods for the synthesis of carbon nanotubes. This method involves the decomposition of gaseous carbon-containing precursors, usually methane, acetylene, or ethylene, in the presence of a catalyst under high temperatures.

Process Overview:

- A substrate (usually a metal catalyst like iron, nickel, or cobalt) is placed in a furnace.

- A carbon-containing gas (such as methane) is introduced into the reaction chamber.

- The gas decomposes under high temperatures (typically 600°C to 1000°C), and carbon atoms are deposited onto the catalyst surface.

- As the carbon atoms accumulate, they form nanotube structures, which can grow vertically or horizontally depending on the conditions.

Advantages:

- Control Over Properties: CVD allows for precise control over the nanotube’s diameter, length, and alignment by adjusting parameters like temperature, gas composition, and catalyst type. This is essential for producing CNTs with specific desired properties.

- High Purity: The process typically results in high-purity CNTs with fewer impurities, which is crucial for many applications in electronics and energy storage.

- Scalability: CVD can be scaled up for industrial production, making it suitable for large-scale synthesis of CNTs for commercial purposes.

- Versatility: By modifying the precursor gases and catalyst materials, CVD can be adapted for the synthesis of both single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs).

Challenges:

- Catalyst Contamination: The catalyst particles can sometimes remain embedded within the CNTs, requiring additional purification steps.

- Temperature Sensitivity: The high temperatures required for CVD can lead to issues with controlling the growth rate and uniformity of the CNTs if not properly managed.

Applications:

CVD-synthesized CNTs are widely used in the fabrication of nanoelectronics, energy storage devices, field emission displays, sensor technology, and nanocomposites.

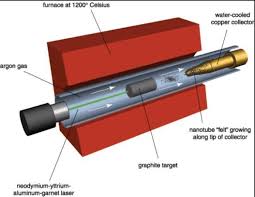

2. Arc Discharge Method

The Arc Discharge Method is another widely used technique for synthesizing carbon nanotubes, especially for producing high-quality single-walled carbon nanotubes (SWCNTs). In this method, a high current is passed between two carbon electrodes under inert gas conditions (such as helium or argon), which generates the conditions needed for CNT formation.

Process Overview:

- Two carbon electrodes (typically graphite) are placed in a chamber filled with an inert gas.

- A high voltage is applied to the electrodes, creating an arc discharge between them.

- The intense heat generated by the arc causes the carbon atoms from the electrodes to vaporize.

- The vaporized carbon condenses on cooler surfaces, forming CNTs. This process may occur at temperatures around 2000°C.

Advantages:

- High Purity SWCNTs: The arc discharge method is particularly effective for producing high-purity single-walled carbon nanotubes. It is one of the best techniques for obtaining pristine CNTs without significant defects.

- Simplicity: The process is relatively simple and can be carried out in a straightforward experimental setup with the right equipment. This simplicity makes it attractive for both research and small-scale production.

- High Yield of CNTs: The method can produce a relatively high yield of CNTs compared to some other methods, especially in terms of high-quality single-walled nanotubes.

Challenges:

- Large Amount of Byproducts: The arc discharge process often produces a significant amount of amorphous carbon and soot, which requires additional purification steps to obtain high-quality CNTs.

- Limited Control: While the process is efficient at producing CNTs, controlling the alignment, length, and chirality of the nanotubes can be more challenging compared to methods like CVD.

- Energy Consumption: The method is energy-intensive due to the high temperatures needed to sustain the arc discharge.

Applications:

The arc discharge method is often employed in research settings where high-quality SWCNTs are required for applications in nanocomposites, electronics, energy storage devices, and supercapacitors.

Conclusion

Both the Chemical Vapor Deposition (CVD) and Arc Discharge methods are highly effective for the synthesis of carbon nanotubes, each with its unique advantages. CVD is preferred for industrial-scale production due to its versatility, scalability, and control over the nanotube’s properties, making it ideal for applications in electronics, energy storage, and nanoelectronics. On the other hand, Arc Discharge is better suited for producing high-purity single-walled carbon nanotubes, often used in specialized applications like nanoelectronics and superconducting materials.

Choosing the right synthesis method depends on factors such as the desired properties of the CNTs, the scale of production, and the specific application. With continued advancements in these synthesis techniques, carbon nanotubes are expected to play a crucial role in a wide range of emerging technologies.