Advanced Applications of Polymer-Nanoclay Composites

Polymer-nanoclay composites represent a fascinating and highly functional class of materials that have gained significant attention in recent years. These materials combine the unique properties of polymers with the advanced characteristics of nanoclay particles, leading to enhanced performance across a range of applications. The nanoclay particles, typically on the nanometer scale, possess exceptional properties such as high surface area, unique mechanical strength, and excellent thermal stability. When dispersed in a polymer matrix, these properties are imparted to the composite, making them suitable for a wide variety of advanced applications in industries such as automotive, aerospace, electronics, packaging, and more.

In this article, we will explore the advanced applications of polymer-nanoclay composites, highlighting how they are revolutionizing industries and offering solutions to modern technological challenges.

What Are Polymer-Nanoclay Composites?

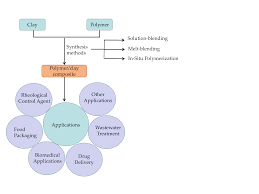

Polymer-nanoclay composites are hybrid materials made by incorporating nanoclay particles into a polymer matrix. The term “nanoclay” refers to naturally occurring, layered silicate minerals such as montmorillonite, which possess an internal structure that can easily intercalate (insert) or exfoliate (disperse) within the polymer matrix. This dispersion results in a unique composite material that exhibits improved properties compared to the individual components.

Key Benefits of Polymer-Nanoclay Composites

- Enhanced Mechanical Properties: Nanoclay particles reinforce the polymer matrix, significantly improving its mechanical strength, stiffness, and toughness. These enhanced properties allow the composites to perform under demanding conditions.

- Improved Thermal Stability: The addition of nanoclay improves the thermal resistance of polymers, making these composites more suitable for high-temperature applications where conventional polymers would typically degrade.

- Barrier Properties: Nanoclay incorporation enhances the barrier properties of the polymer matrix, such as resistance to gas, moisture, and chemicals. This is particularly useful in packaging applications, where these properties are critical for preserving food, pharmaceuticals, and other sensitive products.

- Environmental Resistance: Polymer-nanoclay composites exhibit superior resistance to ultraviolet (UV) radiation, chemicals, and abrasion, making them more durable and long-lasting in outdoor and industrial environments.

- Electrical Conductivity: In some applications, the introduction of nanoclay particles can help create a conductive pathway within the polymer matrix, giving rise to materials with controlled electrical conductivity.

- Improved Processability: Nanoclay-filled polymer composites can be processed using conventional polymer processing techniques such as extrusion, injection molding, and blow molding, making them versatile in manufacturing.

Advanced Applications of Polymer-Nanoclay Composites

- Automotive Industry

Polymer-nanoclay composites have gained prominence in the automotive industry due to their enhanced mechanical and thermal properties. These materials are used to manufacture lightweight, high-performance parts for vehicles, including:

- Interior Components: Nanoclay composites are used for interior car parts like dashboards, door panels, and seating materials. These composites provide a high degree of mechanical strength, impact resistance, and thermal stability, which are essential for automotive applications.

- Exterior Parts: Components like bumpers and trim are made using polymer-nanoclay composites for better durability, resistance to UV degradation, and aesthetic quality.

- Fuel Efficiency: Due to their lightweight nature, polymer-nanoclay composites help reduce the overall weight of vehicles, contributing to improved fuel efficiency and reduced carbon emissions.

- Aerospace Industry

The aerospace industry demands materials that can withstand extreme conditions, including high temperatures, chemical exposure, and significant mechanical stress. Polymer-nanoclay composites are being used in a variety of aerospace applications due to their:

- Lightweight Characteristics: Reducing the weight of aircraft components is crucial for improving fuel efficiency and performance. Nanoclay composites offer a lightweight alternative to traditional materials like metals and plastics without compromising strength or durability.

- Thermal Stability: Aircraft components exposed to high temperatures, such as engine parts and external panels, benefit from the enhanced thermal resistance of polymer-nanoclay composites, ensuring performance in extreme conditions.

- Structural Integrity: The composites’ high mechanical strength and impact resistance make them ideal for parts subjected to mechanical stress during flight.

- Packaging Industry

One of the most widely used applications of polymer-nanoclay composites is in packaging, where they provide exceptional barrier properties to protect food, pharmaceuticals, and other sensitive products. The main benefits include:

- Moisture and Gas Barrier: The nanoclay particles reinforce the polymer matrix, reducing permeability to gases like oxygen and moisture, which helps extend the shelf life of packaged products. This is particularly important in food packaging, where maintaining freshness is key.

- Sustainability: Polymer-nanoclay composites are being used to create biodegradable packaging materials that offer superior strength, barrier properties, and environmental sustainability compared to conventional packaging materials.

- Electronics Industry

Polymer-nanoclay composites are increasingly finding applications in the electronics industry, particularly in:

- Conductive Polymers: By incorporating nanoclay, polymer composites can be engineered to possess controlled electrical conductivity. This makes them suitable for applications such as electronic circuit boards, conductive coatings, and capacitors.

- Thermal Management: Electronics often generate significant amounts of heat, and materials with high thermal conductivity are required to dissipate heat efficiently. Nanoclay composites improve the heat dissipation properties of polymers, helping to prevent overheating and improve the reliability and longevity of electronic devices.

- Flexible Electronics: The combination of lightweight and flexible properties makes polymer-nanoclay composites ideal for the development of flexible electronic devices, such as wearables, flexible displays, and sensors.

- Medical and Biomedical Applications

Polymer-nanoclay composites are being explored for use in medical and biomedical applications, including:

- Implants and Prosthetics: The biocompatibility, mechanical strength, and wear resistance of these composites make them suitable for manufacturing medical implants and prosthetics that require long-term durability in the human body.

- Wound Dressings: The ability of polymer-nanoclay composites to control the release of drugs, as well as their antibacterial properties, makes them useful in creating advanced wound dressings.

- Construction and Coatings

Polymer-nanoclay composites are increasingly used in construction materials and coatings due to their durability and resistance to environmental degradation:

- Waterproof Coatings: These composites are used to produce waterproof coatings for building materials, providing protection against moisture and chemical exposure.

- Thermal Insulation: Due to their improved thermal properties, polymer-nanoclay composites are also used in insulating materials, such as roofing and wall panels, to help conserve energy in buildings.

- Durable Coatings: In industrial and infrastructure applications, polymer-nanoclay composites are used for protective coatings that enhance the longevity of equipment, machinery, and infrastructure against corrosion and wear.

Challenges and Future Directions

While polymer-nanoclay composites offer significant benefits, challenges still exist in their widespread adoption:

- Dispersibility of Nanoclay: Achieving a uniform dispersion of nanoclay particles within the polymer matrix is crucial for realizing the full potential of the composite. Poor dispersion can lead to agglomeration, which reduces the desired properties.

- Cost: The high cost of nanoclay materials and processing methods can limit the widespread commercialization of polymer-nanoclay composites. As manufacturing processes improve, these costs are expected to decrease.

- Environmental Impact: Although nanoclay is a naturally occurring material, the production and disposal of polymer-nanoclay composites should be managed to minimize environmental impact, especially when using non-biodegradable polymers.

Future research efforts are focused on enhancing the compatibility between nanoclay and different polymers, developing new processing techniques, and exploring sustainable and eco-friendly options for these composites.

Conclusion

Polymer-nanoclay composites are versatile, high-performance materials with a broad range of advanced applications across industries such as automotive, aerospace, electronics, packaging, and healthcare. The incorporation of nanoclay into polymers imparts enhanced mechanical, thermal, barrier, and electrical properties, making these composites highly desirable for a variety of demanding applications. While challenges remain, ongoing research and development efforts are paving the way for even more innovative uses of polymer-nanoclay composites in the future, contributing to advancements in technology, sustainability, and manufacturing.