Metal-Air Batteries: The Ultimate Guide & Applications

Metal-air batteries have emerged as a promising energy storage technology due to their high energy density and lightweight design. These batteries, including lithium-air, zinc-air, and aluminum-air types, are considered potential game-changers in the fields of electric vehicles (EVs), renewable energy storage, and portable electronics. Metal-air batteries work by using metal as the anode and oxygen from the air as the cathode, a configuration that makes them fundamentally different from traditional rechargeable batteries like lithium-ion batteries.

In this comprehensive guide, we explore the workings of metal-air batteries, their various types, advantages, challenges, and the future applications of this advanced nanomaterial-based energy storage system.

What Are Metal-Air Batteries?

Metal-air batteries are a type of primary or secondary battery that utilizes the electrochemical reaction between a metal anode (such as zinc, lithium, or aluminum) and oxygen from the air as the cathode. The key distinguishing feature of metal-air batteries is their use of air as a reactant instead of a traditional cathode material, which leads to exceptional energy density.

Unlike conventional rechargeable batteries, metal-air batteries rely on oxygen, which is freely available from the air, instead of storing the cathode material. This significantly reduces the battery’s weight and makes them more cost-effective and efficient in terms of energy storage.

Types of Metal-Air Batteries

There are several types of metal-air batteries, each with its unique characteristics and potential applications:

- Zinc-Air Batteries:

- Zinc-air batteries are one of the most widely researched types of metal-air batteries. They use zinc as the anode and oxygen from the air as the cathode. These batteries offer a relatively low cost and high energy density, making them suitable for applications such as hearing aids and small electronics. However, challenges with battery rechargeability and cyclic stability limit their widespread use in larger applications.

- Lithium-Air Batteries:

- Lithium-air batteries are considered the most promising metal-air batteries due to their extremely high energy density. They use lithium metal as the anode and oxygen from the air as the cathode. Lithium-air batteries have the potential to surpass lithium-ion batteries in terms of energy storage, which could revolutionize industries such as electric vehicles (EVs) and grid-scale energy storage. However, issues like poor cycling stability and inefficiency in recharging remain key challenges in their development.

- Aluminum-Air Batteries:

- Aluminum-air batteries use aluminum as the anode and oxygen from the air as the cathode. They are known for their lightweight design and high energy density, making them ideal for electric vehicles and military applications. However, they currently suffer from issues related to limited reusability and difficulties in maintaining the integrity of the aluminum anode over multiple cycles.

- Magnesium-Air Batteries:

- Magnesium-air batteries are another variation that utilizes magnesium as the anode and oxygen as the cathode. These batteries have a higher theoretical energy density than zinc-air batteries and offer better safety profiles than lithium-air batteries. They are still under research, with the goal of overcoming issues related to the cost and stability of magnesium-based systems.

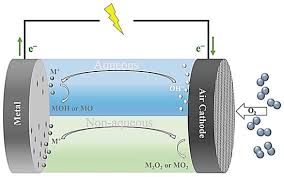

How Metal-Air Batteries Work

Metal-air batteries operate on a simple principle: a metal anode (such as zinc, lithium, or aluminum) reacts with oxygen from the air, producing electricity and releasing by-products. The process occurs in two main steps:

- Anode Reaction: The metal at the anode undergoes an oxidation reaction, releasing electrons and creating positive ions.

- Cathode Reaction: The oxygen in the air is reduced at the cathode, combining with the positive ions from the anode and the electrons traveling through the external circuit to form hydroxide or other compounds.

This overall reaction produces electricity as a result of the flow of electrons through the external circuit. The key difference between metal-air and other battery technologies is the use of oxygen from the air instead of a conventional cathode material, which leads to a significantly higher energy density.

Advantages of Metal-Air Batteries

Metal-air batteries offer several advantages, particularly in terms of energy density and sustainability:

- High Energy Density: Metal-air batteries have the potential to offer much higher energy densities than traditional lithium-ion batteries due to the use of air as a reactant. For example, lithium-air batteries theoretically offer an energy density that is 10 times higher than conventional lithium-ion batteries.

- Lightweight: Since the cathode material (oxygen) is extracted from the air, metal-air batteries are lighter compared to conventional batteries that require a heavy cathode material.

- Cost Efficiency: Many metal-air batteries use abundant, low-cost metals like zinc and aluminum, which makes them relatively inexpensive compared to traditional battery technologies.

- Environmentally Friendly: Metal-air batteries, especially those using zinc or aluminum, are more environmentally friendly than batteries that rely on toxic or rare materials, such as lithium and cobalt.

- Extended Range for Electric Vehicles: Given their high energy density, metal-air batteries could provide electric vehicles (EVs) with significantly extended driving range, making them a viable alternative to lithium-ion batteries in the future.

Challenges of Metal-Air Batteries

While metal-air batteries offer several benefits, they also face a range of challenges that must be addressed to enable their widespread use:

- Rechargeability: One of the most significant challenges for metal-air batteries, especially lithium-air and zinc-air batteries, is their poor rechargeability. The reactions at the anode and cathode can degrade over time, reducing the battery’s capacity and efficiency.

- Cycling Stability: Metal-air batteries often suffer from poor cycling stability, meaning they lose their ability to hold charge over many cycles. This is a particular issue for lithium-air and aluminum-air batteries.

- Air Contaminants: Since metal-air batteries use oxygen from the air as the cathode, the presence of humidity and carbon dioxide can interfere with the chemical reactions, leading to efficiency loss and reduced battery lifespan.

- Structural Integrity: In some metal-air battery types, such as aluminum-air, the anode may degrade or corrode during the reaction, which limits the battery’s lifespan and performance.

- Cost of Materials: While metals like zinc and aluminum are abundant, lithium-air batteries require lithium, which is expensive, and air filters may increase the cost of these batteries.

Applications of Metal-Air Batteries

Despite the challenges, metal-air batteries hold great potential for a range of applications:

- Electric Vehicles (EVs):

- Metal-air batteries, particularly lithium-air and zinc-air batteries, are being researched as a solution to extend the driving range of electric vehicles. Their high energy density could offer a longer driving range than current lithium-ion batteries.

- Grid-Scale Energy Storage:

- The high energy density of metal-air batteries makes them ideal for energy storage systems that can store excess energy generated from renewable sources, such as solar and wind. They could help balance the grid by storing energy during peak production and releasing it when demand is high.

- Consumer Electronics:

- Zinc-air batteries are already used in small devices like hearing aids and watch batteries. With further advancements, they could be used in other portable electronic devices.

- Military and Aerospace Applications:

- Aluminum-air batteries are being explored for use in military and aerospace applications due to their high energy density and lightweight nature. These batteries could power unmanned aerial vehicles (UAVs) or provide backup power in remote operations.

- Portable Power Systems:

- Metal-air batteries have potential in portable power generation applications due to their ability to deliver a high energy output relative to their size and weight, making them ideal for off-grid and emergency backup systems.

Conclusion

Metal-air batteries represent an exciting advancement in energy storage technology. With their high energy density, lightweight design, and cost-efficiency, they are well-suited for applications in electric vehicles, renewable energy storage, and consumer electronics. While challenges such as rechargeability and cycling stability remain, ongoing research and development are focused on overcoming these hurdles. The potential for metal-air batteries to revolutionize energy storage and reduce carbon emissions makes them a promising technology for the future of clean energy and sustainable power solutions.