Laser-Induced Graphene: Paving the Way for Innovative Implementations

Introduction

In recent years, Laser-Induced Graphene (LIG) has emerged as a groundbreaking material that is reshaping the landscape of various industries, including energy storage, electronics, and environmental applications. LIG is created by exposing carbon-containing materials to a laser, which induces a highly porous, conductive graphene structure. This versatile material has unlocked numerous potential applications, thanks to its impressive properties such as high electrical conductivity, mechanical strength, and surface area. In this article, we will explore how Laser-Induced Graphene is paving the way for innovative implementations across various sectors.

1. What is Laser-Induced Graphene?

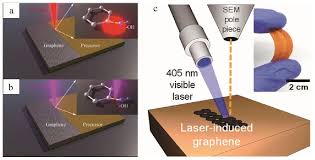

Laser-Induced Graphene (LIG) is a form of graphene that is produced by direct laser irradiation of carbon-rich materials, such as polymers, wood, or plastic. The process involves the use of a femtosecond or nanosecond laser to heat the surface of the material, causing the carbon atoms to reorganize into a graphene-like structure. This technique can be performed without the need for complex or expensive chemical processes, making it an attractive alternative for large-scale production of graphene.

LIG typically has a highly porous structure, which increases its surface area and enhances properties such as electrical conductivity and mechanical strength. The process is highly adaptable, allowing for the creation of LIG on a variety of substrates, ranging from biological tissues to industrial materials.

2. How Laser-Induced Graphene Is Made

The process of making Laser-Induced Graphene begins by selecting a carbon-containing precursor material. Common materials used include:

- Polyimide films

- Wood

- Plastic films

- Paper

- Cotton fabrics

Once the precursor is selected, a laser is focused onto the surface of the material. The laser energy breaks the molecular bonds in the precursor material and causes the carbon atoms to rearrange into a graphene-like lattice structure. The result is a highly conductive, porous surface with a range of unique properties that are ideal for many applications.

One of the main advantages of the laser-induced process is its simplicity and cost-effectiveness. Traditional methods of graphene production often involve expensive chemical vapor deposition (CVD) or other complex techniques, whereas LIG can be achieved using simple laser equipment, making it more accessible for a wider range of industries.

3. Key Properties of Laser-Induced Graphene

Laser-Induced Graphene boasts a set of remarkable properties that make it a valuable material for various advanced applications:

A. High Electrical Conductivity

LIG exhibits excellent electrical conductivity due to the formation of a graphene-like structure, which is known for its high electron mobility. This property makes LIG ideal for use in applications such as supercapacitors, batteries, and electronic circuits.

B. Porous Structure

The laser-induced process produces a highly porous surface, which greatly enhances the surface area of the material. This is a critical feature for energy storage devices, such as supercapacitors and batteries, where a larger surface area allows for greater charge storage capacity.

C. Mechanical Strength

Despite its light weight, LIG is known for its exceptional mechanical strength and flexibility. This makes it suitable for use in flexible electronics, wearable devices, and lightweight materials in the automotive and aerospace industries.

D. Environmental Sustainability

LIG can be produced from a variety of waste or low-cost materials, such as wood or biodegradable plastics, making it an environmentally sustainable alternative to traditional graphene production methods, which often rely on toxic chemicals or costly processes.

4. Applications of Laser-Induced Graphene

Laser-Induced Graphene is driving innovations in a wide array of industries. Below are some key sectors where LIG is expected to make a significant impact:

A. Energy Storage (Supercapacitors and Batteries)

LIG’s high electrical conductivity and large surface area make it an excellent material for energy storage devices like supercapacitors and lithium-ion batteries. Supercapacitors, in particular, benefit from LIG’s ability to store a large amount of charge in a short time, making them ideal for high-power applications such as in electric vehicles or portable electronics.

In batteries, LIG can serve as an electrode material, improving energy density and charge/discharge rates. LIG-based energy storage devices are also cost-effective, offering the potential to make energy storage systems more affordable and accessible.

B. Flexible and Wearable Electronics

Due to its mechanical flexibility and electrical properties, LIG is ideal for flexible electronics. It can be used in applications such as wearable devices, stretchable sensors, and smart textiles. The ability to create graphene-based circuits on flexible substrates opens up new possibilities for wearable health monitors, fitness trackers, and other forms of flexible electronics.

C. Environmental Sensors

LIG’s porous nature and conductivity make it an excellent candidate for environmental sensors. These sensors can detect a variety of environmental pollutants, gases, and even biological agents. The low-cost and versatile nature of LIG allow for the development of sensors for real-time monitoring in air quality assessments, water pollution monitoring, and agricultural applications.

D. Water Purification and Filtration

LIG has been shown to have excellent adsorption capabilities, which makes it effective in water purification and filtration applications. Its porous structure can trap heavy metals, organic pollutants, and other toxins, offering a sustainable solution for clean water access in areas where traditional water treatment systems are inadequate.

E. Biomedical Applications

Laser-induced graphene has also demonstrated potential in biomedical applications. Due to its high surface area and biocompatibility, it can be used in the development of drug delivery systems, biosensors, and even in wound healing applications. LIG’s ability to integrate with biological tissues opens up new possibilities in medical diagnostics and therapeutic interventions.

F. Supercapacitors for Electric Vehicles (EVs)

One of the most promising areas for LIG is its use in electric vehicles (EVs). Supercapacitors made from LIG can be used alongside traditional batteries to improve the range and performance of EVs. They can charge faster and provide bursts of energy for acceleration, complementing the energy storage capabilities of lithium-ion batteries.

5. Challenges and Future Outlook

While Laser-Induced Graphene offers many exciting possibilities, there are still several challenges that need to be addressed before it can be widely adopted. These include:

- Scalability: While LIG can be produced in small batches, scaling up the process to produce larger quantities at low cost remains a challenge.

- Optimization of Material Properties: Further research is needed to optimize the properties of LIG for specific applications, including improving its stability, durability, and reliability in various environments.

However, as the technology matures, the potential of Laser-Induced Graphene to revolutionize industries such as energy storage, electronics, and environmental sustainability is immense. Researchers are actively exploring new methods to improve the efficiency and scalability of LIG production, which will likely drive its widespread commercialization.

6. Conclusion

Laser-Induced Graphene represents a game-changing material with vast potential across various industries, from energy storage to biomedicine. Its ability to combine high electrical conductivity, mechanical strength, and environmental sustainability makes it an exciting material for a wide range of applications. As research into LIG continues to advance, it is expected to play a pivotal role in the development of next-generation technologies that will shape the future of electronics, energy, and environmental solutions.