Nanostructured Epoxy Adhesives: Enhancing Bonding Strength and Durability

Epoxy adhesives are widely used in industrial, automotive, and construction applications due to their strong bonding capabilities, durability, and versatility. However, the increasing demand for higher performance in terms of strength, resistance, and longevity has driven the development of nanostructured epoxy adhesives. By incorporating nanomaterials, these adhesives are significantly enhanced, offering superior mechanical properties, thermal resistance, and environmental durability compared to traditional epoxy adhesives.

1. What are Nanostructured Epoxy Adhesives?

Nanostructured epoxy adhesives are modified epoxy-based adhesives that incorporate nanomaterials, such as nanoparticles, nanofillers, and nanotubes, into the adhesive matrix. The integration of these nanomaterials improves the material properties of the epoxy, making it more effective for bonding a wider range of substrates in various demanding applications.

Nanostructured adhesives typically contain nanoparticles such as silica (SiO2), carbon nanotubes (CNTs), graphene, titanium dioxide (TiO2), and clay nanoparticles. These additives are embedded at the nanoscale level within the adhesive to enhance the chemical and mechanical interactions between the adhesive and the bonded surfaces.

2. Advantages of Nanostructured Epoxy Adhesives

A. Enhanced Bonding Strength

Nanostructured epoxy adhesives exhibit improved bonding strength due to the increased surface area of the nanomaterials. These particles form stronger chemical and physical interactions with the substrates, resulting in higher shear and tensile strengths. This makes them ideal for use in high-stress environments, such as in the automotive, aerospace, and construction industries.

B. Improved Thermal and Chemical Resistance

Nanoparticles, such as silica and graphene, provide enhanced thermal and chemical resistance to epoxy adhesives. This allows nanostructured adhesives to withstand extreme temperatures and harsh chemical environments without degrading, which is crucial in applications like automotive engine components, aerospace equipment, and marine environments.

C. Superior Toughness and Durability

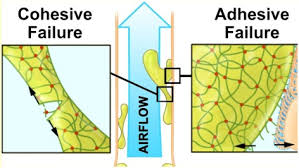

Incorporating nanomaterials into the epoxy matrix can improve the fracture toughness of the adhesive. Nanostructured adhesives are more resistant to cracking and deformation, offering improved impact resistance and fatigue resistance. These qualities are especially important in applications that experience repeated loading or high mechanical stresses, such as in structural bonding and composite materials.

D. Improved Curing Properties

Nanostructured epoxy adhesives can offer improved curing behavior, allowing for faster curing times and better performance at various temperatures. This is particularly useful in industrial assembly lines where time efficiency and optimal bonding are crucial.

E. Enhanced Barrier Properties

Nanoparticles can enhance the barrier properties of epoxy adhesives, making them more resistant to moisture, gases, and environmental degradation. This can be especially beneficial for electronic devices, automotive applications, and packaging materials, where protection from moisture and corrosion is essential.

F. Better Electrical and Conductive Properties

Certain nanomaterials, such as carbon nanotubes (CNTs) and graphene, can improve the electrical conductivity of epoxy adhesives, which is valuable in applications involving electrical connections or electronics packaging. The improved conductivity can contribute to enhanced performance in circuits and sensors.

3. Types of Nanomaterials Used in Epoxy Adhesives

Several nanomaterials can be integrated into epoxy adhesives to achieve specific enhancements:

A. Silica (SiO2) Nanoparticles

Silica nanoparticles are commonly used to improve the mechanical strength, thermal resistance, and viscosity of epoxy adhesives. They increase the viscoelastic properties and provide better adhesion to a variety of surfaces.

B. Carbon Nanotubes (CNTs)

Carbon nanotubes are one of the most promising nanomaterials for enhancing the mechanical strength, toughness, and electrical conductivity of epoxy adhesives. CNTs form a network-like structure within the adhesive, improving its stress distribution and enhancing its conductive properties.

C. Graphene

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, is known for its exceptional strength, flexibility, and conductivity. When added to epoxy adhesives, graphene enhances their mechanical properties, electrical conductivity, and thermal stability.

D. Titanium Dioxide (TiO2)

Titanium dioxide nanoparticles improve the UV resistance and corrosion resistance of epoxy adhesives, making them suitable for outdoor applications. TiO2 also provides photocatalytic properties, which can be useful for self-cleaning surfaces in certain adhesive applications.

E. Clay Nanoparticles

Clay nanoparticles, such as montmorillonite, are used to improve the barrier properties and viscosity of epoxy adhesives. These materials can enhance the resistance of the adhesive to gases, liquids, and solvents.

4. Applications of Nanostructured Epoxy Adhesives

The enhanced properties of nanostructured epoxy adhesives make them ideal for a variety of applications across different industries:

A. Automotive Industry

In the automotive sector, nanostructured epoxy adhesives are used for structural bonding of components, such as metal, plastic, and composite parts. They provide high strength and durability, improving vehicle safety and performance. These adhesives also help in the manufacture of lightweight vehicles by bonding composite materials.

B. Aerospace Industry

Nanostructured epoxy adhesives are extensively used in the aerospace industry for bonding critical components such as aircraft wings, fuselage parts, and electronic components. Their ability to withstand extreme temperatures, pressures, and chemical exposure makes them perfect for aerospace applications.

C. Electronics and Electrical Devices

Nanostructured epoxy adhesives are used in electronics packaging, such as semiconductor bonding, sensors, and LEDs. The improved electrical conductivity and thermal stability make them suitable for power electronics and circuit board applications.

D. Construction and Infrastructure

In the construction sector, these adhesives are used for bonding materials like steel, concrete, and glass. Their superior durability and resistance to environmental factors make them ideal for use in building facades, roads, and bridges.

E. Marine Industry

In marine applications, nanostructured epoxy adhesives are used for bonding components in boats, ships, and underwater structures. Their resistance to water, moisture, and corrosion is essential for maintaining the longevity of these structures.

5. Challenges and Future Directions

Despite the numerous advantages, the widespread adoption of nanostructured epoxy adhesives faces some challenges:

A. Cost of Production

The incorporation of nanomaterials into epoxy adhesives can increase the production cost. However, as research progresses and manufacturing techniques improve, the cost of production is expected to decrease, making these adhesives more accessible.

B. Consistency and Dispersion of Nanoparticles

Achieving uniform dispersion of nanoparticles within the epoxy matrix is a challenge. Agglomeration of nanoparticles can reduce the effectiveness of the adhesive. Ongoing research is focused on improving the dispersion techniques to ensure consistent performance.

C. Regulatory and Safety Concerns

The use of nanoparticles in adhesives raises concerns about their environmental impact and health safety. Regulatory agencies are continuously evaluating the safety of nanomaterials, and guidelines will be established to ensure the safe use of nanostructured epoxy adhesives.

6. Conclusion

Nanostructured epoxy adhesives represent a significant advancement in bonding technology. By incorporating nanomaterials like silica, carbon nanotubes, graphene, and titanium dioxide, these adhesives offer improved mechanical strength, thermal stability, chemical resistance, and electrical conductivity. As a result, they find applications in a wide range of industries, including automotive, aerospace, electronics, and construction. While challenges related to cost and nanoparticle dispersion exist, the continued development of nanostructured epoxy adhesives promises even more innovative and high-performance solutions for bonding applications in the future.