3 Best Application Areas of Graphene Nanoplatelets

Introduction

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, has generated immense interest in the scientific community for its extraordinary properties. When in the form of graphene nanoplatelets (GNPs)—which are multiple layers of graphene stacked together—these materials exhibit enhanced performance in various industries. GNPs combine the unique properties of graphene, such as high electrical conductivity, mechanical strength, thermal conductivity, and flexibility, with the advantages of being easy to synthesize, scalable, and versatile.

In this article, we will discuss the three best application areas of graphene nanoplatelets, exploring how they are transforming industries such as electronics, energy storage, and composite materials.

1. Energy Storage and Supercapacitors

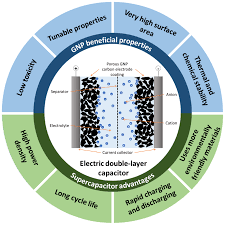

Graphene nanoplatelets are a key material in the development of advanced energy storage systems, particularly supercapacitors and batteries. The high surface area, electrical conductivity, and structural properties of GNPs make them ideal for use in energy storage applications, where efficient charge/discharge cycles, high energy density, and long cycle life are critical.

Supercapacitors:

Supercapacitors, or ultracapacitors, store energy through electrostatic fields, unlike traditional batteries, which store energy chemically. They are used in applications requiring fast bursts of energy and long cycle life. GNPs are incorporated into supercapacitor electrodes to enhance charge storage capacity and rate capability.

- High Surface Area: Graphene nanoplatelets provide an extensive surface area that increases the charge storage capacity of supercapacitors. The more surface area available, the more ions can be adsorbed, leading to increased energy density.

- Enhanced Conductivity: GNPs also improve the electrical conductivity of the electrodes, facilitating faster charging and discharging cycles, which is essential for applications like electric vehicles, power grids, and consumer electronics.

- Durability: The mechanical strength and structural integrity of graphene nanoplatelets help in maintaining long-term performance and improving the cycle life of supercapacitors.

Lithium-Ion and Sodium-Ion Batteries:

Graphene nanoplatelets are also being studied as anode materials in lithium-ion and sodium-ion batteries. The addition of GNPs to the electrode materials enhances conductivity, capacity, and charge/discharge cycles of batteries, making them an attractive alternative to conventional battery materials.

Example: Leading companies, including Tesla and Samsung, are exploring the use of GNPs to improve the energy storage capacity and performance of lithium-ion and sodium-ion batteries, potentially leading to batteries that can store more energy and last longer with faster charging times.

2. Composite Materials for Aerospace, Automotive, and Construction Industries

Graphene nanoplatelets are revolutionizing the composite materials industry by improving the performance and durability of materials used in industries like aerospace, automotive, and construction. The incorporation of GNPs into composites imparts exceptional properties such as lightweight, strength, conductivity, and resistance to wear and tear.

Aerospace and Automotive:

In both aerospace and automotive industries, weight reduction is a major goal. Graphene nanoplatelets can significantly improve the mechanical strength of lightweight composites, allowing vehicles and aircraft to achieve better fuel efficiency and performance without compromising on durability.

- Enhanced Mechanical Properties: GNPs improve the tensile strength, flexural strength, and impact resistance of composites, making them more robust and resistant to damage.

- Thermal Conductivity: Graphene nanoplatelets enhance the thermal conductivity of composites, which is essential for managing heat in high-performance components such as engine parts, brake systems, and exhausts in vehicles and aerospace applications.

- Lightweight Materials: The low density of graphene nanoplatelets allows for the creation of lightweight yet strong composites, which is crucial for fuel efficiency in both the automotive and aerospace industries.

Example: The aircraft manufacturer Airbus and automotive companies such as BMW are researching graphene-infused composite materials to make lighter, stronger, and more energy-efficient vehicles and components.

Construction:

In construction, graphene nanoplatelets are being integrated into materials like concrete and steel to enhance strength, durability, and resistance to environmental factors. GNPs improve crack resistance, longevity, and thermal properties of construction materials, contributing to more sustainable and durable buildings.

- Self-Healing Concrete: By incorporating GNPs into concrete, self-healing properties can be achieved. The graphene nanoparticles can facilitate the repair of cracks and increase the lifespan of the structures.

- Corrosion Resistance: Graphene nanoplatelets enhance the corrosion resistance of metals used in construction, ensuring the longevity of buildings exposed to harsh environmental conditions.

Example: In partnership with research institutions, construction companies like Saint-Gobain and LafargeHolcim are exploring graphene-enhanced concrete for stronger and longer-lasting buildings.

3. Sensors and Flexible Electronics

The high electrical conductivity and flexibility of graphene nanoplatelets make them ideal for applications in sensors and flexible electronics. The ability to create highly sensitive, lightweight, and flexible devices opens up new possibilities for wearable electronics, health monitoring, and environmental sensing.

Sensors:

Graphene nanoplatelets are used in chemical, biosensors, and gas sensors due to their high surface area and electrical properties, which make them highly sensitive to environmental changes. By functionalizing the surface of GNPs, it is possible to detect a wide variety of gases or biological markers at very low concentrations.

- High Sensitivity: The surface reactivity of graphene nanoplatelets allows them to interact with small amounts of substances, making them ideal for sensitive detection applications.

- Fast Response Time: The electrical conductivity of GNPs ensures that sensors can detect changes quickly, enabling real-time monitoring for applications like pollution monitoring, health diagnostics, and food safety.

Example: Researchers at MIT and Stanford have developed highly sensitive gas sensors using graphene nanoplatelets for detecting air pollutants in industrial and urban environments, contributing to better environmental management.

Flexible Electronics:

Graphene nanoplatelets also hold great promise in the field of flexible electronics. Their mechanical flexibility, combined with their electrical properties, enables the development of ultra-thin, bendable electronic devices, such as wearable sensors, OLED displays, and flexible batteries.

- Flexible Displays: Graphene-based composites are used in the production of bendable screens for consumer electronics such as smartphones, tablets, and smartwatches.

- Wearable Electronics: Graphene nanoplatelets are used in wearable health monitors, where the flexibility and conductivity are critical for continuous health monitoring without discomfort.

Example: Companies like Samsung and LG are exploring the use of graphene-enhanced materials to create flexible and foldable electronic devices, pushing the boundaries of consumer electronics design.

Conclusion

Graphene nanoplatelets (GNPs) are paving the way for innovations across multiple industries due to their exceptional properties, including high conductivity, strength, flexibility, and surface area. The three key application areas where GNPs are showing significant promise include:

- Energy storage: Improving the performance of supercapacitors and batteries with higher energy density, faster charging, and longer lifespans.

- Composite materials: Enhancing the mechanical, thermal, and electrical properties of materials used in aerospace, automotive, and construction industries.

- Sensors and flexible electronics: Enabling the development of ultra-sensitive, flexible devices for applications in healthcare, environmental monitoring, and wearable technology.

As research continues, the applications of graphene nanoplatelets are expected to expand, potentially revolutionizing not only electronic and energy storage technologies but also contributing to sustainability and smart manufacturing. The future of GNPs is incredibly promising, and their integration into emerging technologies will likely lead to even more groundbreaking innovations.